CESA BROCHURE - Clariant

CESA BROCHURE - Clariant

CESA BROCHURE - Clariant

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

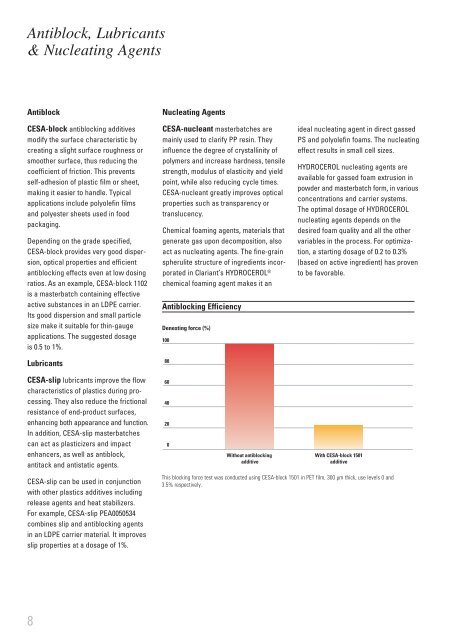

Antiblock, Lubricants& Nucleating AgentsAntiblock<strong>CESA</strong>-block antiblocking additivesmodify the surface characteristic bycreating a slight surface roughness orsmoother surface, thus reducing thecoefficient of friction. This preventsself-adhesion of plastic film or sheet,making it easier to handle. Typicalapplications include polyolefin filmsand polyester sheets used in foodpackaging.Depending on the grade specified,<strong>CESA</strong>-block provides very good dispersion,optical properties and efficientantiblocking effects even at low dosingratios. As an example, <strong>CESA</strong>-block 1102is a masterbatch containing effectiveactive substances in an LDPE carrier.Its good dispersion and small particlesize make it suitable for thin-gaugeapplications. The suggested dosageis 0.5 to 1%.Flame-retardant ratingaccording to UL94 testingV-0Nucleating Agents<strong>CESA</strong>-nucleant masterbatches aremainly used to clarify PP resin. Theyinfluence the degree of crystallinity ofpolymersV-1and increase hardness, tensilestrength, modulus of elasticity and yieldpoint, while also reducing cycle times.<strong>CESA</strong>-nucleant greatly improves opticalV-2properties such as transparency ortranslucency.Denesting force (%)100halogen-containingflame retardantsideal nucleating agent in direct gassedPS and polyolefin foams. The nucleatingeffect results in small cell sizes.HYDROCEROL nucleating agents areavailable for gassed foam extrusion inpowder and masterbatch form, in variousconcentrations and carrier systems.The optimal dosage of HYDROCEROLhalogen-freeflame retardants nucleating agents depends on thenon-classifiedChemical foaming agents, materials that desired foam quality and all the othergenerate 0 gas upon decomposition, 10 also variables 20 in the process. For optimization,a starting (%) dosage of 0.2 to 0.3%30act as nucleating agents. Addition The fine-grain level of flame retardants(based on active ingredient) has provento be favorable.spherulite structure of ingredients incorporatedin <strong>Clariant</strong>’s HYDROCEROL ®chemical foaming agent makes it anAntiblocking EfficiencyLubricants80<strong>CESA</strong>-slip lubricants improve the flowcharacteristics of plastics during processing.They also reduce the frictionalresistance of end-product surfaces,enhancing both appearance and function.In addition, <strong>CESA</strong>-slip masterbatchescan act as plasticizers and impactenhancers, as well as antiblock,antitack and antistatic agents.6040200Without antiblockingadditiveWith <strong>CESA</strong>-block 1501additive<strong>CESA</strong>-slip can be used in conjunctionwith other plastics additives includingrelease agents and heat stabilizers.For example, <strong>CESA</strong>-slip PEA0050534combines slip and antiblocking agentsin an LDPE carrier material. It improvesslip properties at a dosage of 1%.This blocking force test was conducted using <strong>CESA</strong>-block 1501 in PET film, 300 µm thick, use levels 0 and3.5% respectively.8