The enTerprises effecT - Correction Enterprises

The enTerprises effecT - Correction Enterprises

The enTerprises effecT - Correction Enterprises

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

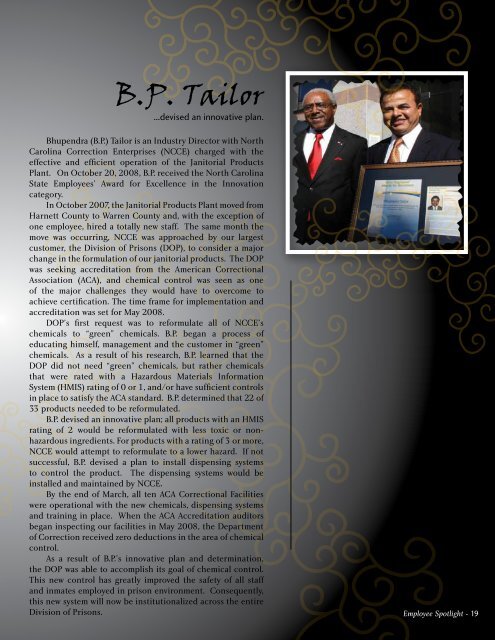

B.P. Tailor...devised an innovative plan.Bhupendra (B.P.) Tailor is an Industry Director with NorthCarolina <strong>Correction</strong> <strong>Enterprises</strong> (NCCE) charged with theeffective and efficient operation of the Janitorial ProductsPlant. On October 20, 2008, B.P. received the North CarolinaState Employees’ Award for Excellence in the Innovationcategory.In October 2007, the Janitorial Products Plant moved fromHarnett County to Warren County and, with the exception ofone employee, hired a totally new staff. <strong>The</strong> same month themove was occurring, NCCE was approached by our largestcustomer, the Division of Prisons (DOP), to consider a majorchange in the formulation of our janitorial products. <strong>The</strong> DOPwas seeking accreditation from the American <strong>Correction</strong>alAssociation (ACA), and chemical control was seen as oneof the major challenges they would have to overcome toachieve certification. <strong>The</strong> time frame for implementation andaccreditation was set for May 2008.DOP’s first request was to reformulate all of NCCE’schemicals to “green” chemicals. B.P. began a process ofeducating himself, management and the customer in “green”chemicals. As a result of his research, B.P. learned that theDOP did not need “green” chemicals, but rather chemicalsthat were rated with a Hazardous Materials InformationSystem (HMIS) rating of 0 or 1, and/or have sufficient controlsin place to satisfy the ACA standard. B.P. determined that 22 of33 products needed to be reformulated.B.P. devised an innovative plan; all products with an HMISrating of 2 would be reformulated with less toxic or nonhazardousingredients. For products with a rating of 3 or more,NCCE would attempt to reformulate to a lower hazard. If notsuccessful, B.P. devised a plan to install dispensing systemsto control the product. <strong>The</strong> dispensing systems would beinstalled and maintained by NCCE.By the end of March, all ten ACA <strong>Correction</strong>al Facilitieswere operational with the new chemicals, dispensing systemsand training in place. When the ACA Accreditation auditorsbegan inspecting our facilities in May 2008, the Departmentof <strong>Correction</strong> received zero deductions in the area of chemicalcontrol.As a result of B.P.’s innovative plan and determination,the DOP was able to accomplish its goal of chemical control.This new control has greatly improved the safety of all staffand inmates employed in prison environment. Consequently,this new system will now be institutionalized across the entireDivision of Prisons.Employee Spotlight - 19