THERMOPLASTIC ELASTOMERS - Softer Group

THERMOPLASTIC ELASTOMERS - Softer Group

THERMOPLASTIC ELASTOMERS - Softer Group

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

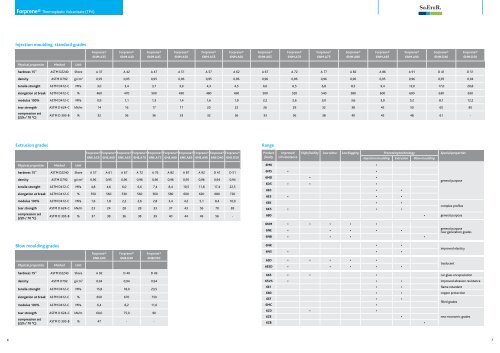

Forprene® Thermoplastic Vulcanizate (TPV)Injection moulding, standard gradesForprene®6NM.A35Forprene®6NM.A40Forprene®6NM.A45Forprene®6NM.A50Forprene®6NM.A55Forprene®6NM.A60Forprene®6NM.A65Forprene®6NM.A70Forprene®6NM.A75Forprene®6NM.A80Forprene®6NM.A85Forprene®6NM.A90Forprene®6NM.D40Forprene®6NM.D50Physical properties Method Unithardness 15'' ASTM D2240 Shore A 37 A 42 A 47 A 51 A 57 A 62 A 67 A 72 A 77 A 82 A 86 A 91 D 41 D 51density ASTM D792 g/cm 3 0,95 0,95 0,95 0,96 0,95 0,96 0,96 0,96 0,96 0,96 0,95 0,96 0,95 0,94tensile strenght ASTM D412-C MPa 3,0 3,4 3,7 3,9 4,3 4,5 6,0 6,5 6,8 8,5 9,4 12,0 17,0 20,8elongation at break ASTM D412-C % 460 470 500 490 480 490 500 520 540 580 600 600 630 650modulus 100% ASTM D412-C MPa 0,9 1,1 1,3 1,4 1,6 1,9 2,2 2,6 3,0 3,6 3,9 5,2 8,1 12,2tear strength ASTM D 624-C kN/m 14 16 17 17 20 22 26 29 32 38 45 50 65 85compression set(22h / 70 °C)ASTM D 395-B % 32 36 36 33 32 36 33 36 38 40 45 48 61 -Extrusion gradesRangeForprene®6NE.A55Forprene®6NE.A60Forprene®6NE.A65Forprene®6NE.A70Forprene®6NE.A75Forprene®6NE.A80Forprene®6NE.A85Forprene®6NE.A90Forprene® Forprene®6NE.D40 6NE.D50ProductfamilyImprovedUV resistanceHigh fluidity Low odour Low fogging Processing technology Special propertiesInjection moulding Extrusion Blow mouldingPhysical properties Method Unithardness 15'' ASTM D2240 Shore A 57 A 61 A 67 A 72 A 76 A 82 A 87 A 92 D 41 D 51density ASTM D792 g/cm 3 0,96 0,95 0,96 0,96 0,96 0,96 0,95 0,96 0,94 0,94tensile strenght ASTM D412-C MPa 4,8 4,6 6,0 6,6 7,4 8,4 10,5 11,8 17,4 22,5elongation at break ASTM D412-C % 550 560 530 560 560 580 600 620 680 720modulus 100% ASTM D412-C MPa 1,6 1,8 2,2 2,6 2,8 3,4 4,2 5,1 8,4 10,9tear strength ASTM D 624-C kN/m 23 24 28 28 33 37 43 56 70 83compression set(22h / 70 °C)Blow moulding gradesASTM D 395-B % 37 38 36 38 39 40 44 49 56 -Physical properties Method UnitForprene®6NB.A90Forprene®6NB.D40Forprene®6NB.D50hardness 15'' ASTM D2240 Shore A 92 D 40 D 49density ASTM D792 g/cm 3 0,94 0,94 0,94tensile strenght ASTM D412-C MPa 15,8 18,0 23,5elongation at break ASTM D412-C % 650 670 750modulus 100% ASTM D412-C MPa 6,4 8,2 11,0tear strength ASTM D 624-C kN/m 60,0 75,0 90compression set(22h / 70 °C)ASTM D 395-B % 47 - -6M06M5 • •6MD • •6D5 • • •6E0 • •6E5 • • •6EK • •6K5 • • ••general purposecomplex profiles6B0 • general purpose6NM • • • • •6NE • • • • •6NB • • • •6NK • •6N5 • • •6SD • • • • •6ESD • • • • •general purposenew generation gradesimproved elasticytraslucent665 • • • car glass encapsulation65VS • • • improved abrasion resistance6E1 • • flame retardant680 • • copper protection6EF • •6MC6Z0 • •6ZE6ZB•••filled gradesnew economic grades6 7