Electrical - usaid

Electrical - usaid

Electrical - usaid

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Executive Summary<br />

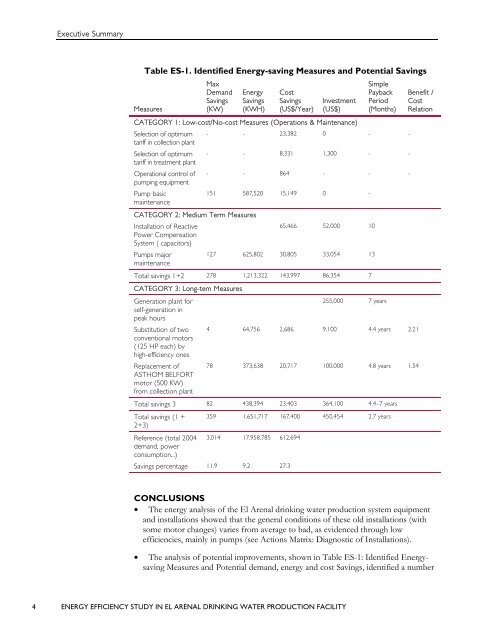

Table ES-1. Identified Energy-saving Measures and Potential Savings<br />

Max<br />

Simple<br />

Demand Energy Cost<br />

Payback Benefit /<br />

Savings Savings Savings Investment Period Cost<br />

Measures<br />

(KW) (KWH) (US$/Year) (US$) (Months) Relation<br />

CATEGORY 1: Low-cost/No-cost Measures (Operations & Maintenance)<br />

Selection of optimum<br />

tariff in collection plant<br />

- - 23,382 0 - -<br />

Selection of optimum<br />

tariff in treatment plant<br />

- - 8,331 1,300 - -<br />

Operational control of<br />

pumping equipment<br />

- - 864 - - -<br />

Pump basic<br />

maintenance<br />

151 587,520 15,149 0 -<br />

CATEGORY 2: Medium Term Measures<br />

Installation of Reactive<br />

Power Compensation<br />

System ( capacitors)<br />

65,466 52,000 10<br />

Pumps major<br />

maintenance<br />

127 625,802 30,805 33,054 13<br />

Total savings 1+2 278 1,213,322 143,997 86,354 7<br />

CATEGORY 3: Long-tem Measures<br />

Generation plant for<br />

self-generation in<br />

peak hours<br />

Substitution of two<br />

conventional motors<br />

(125 HP each) by<br />

high-efficiency ones<br />

Replacement of<br />

ASTHOM BELFORT<br />

motor (500 KW)<br />

from collection plant<br />

4 ENERGY EFFICIENCY STUDY IN EL ARENAL DRINKING WATER PRODUCTION FACILITY<br />

255,000 7 years<br />

4 64,756 2,686 9,100 4.4 years 2.21<br />

78 373,638 20,717 100,000 4.8 years 1.54<br />

Total savings 3 82 438,394 23,403 364,100 4.4–7 years<br />

Total savings (1 +<br />

2+3)<br />

359 1,651,717 167,400 450,454 2.7 years<br />

Reference (total 2004<br />

demand, power<br />

consumption...)<br />

3,014 17,958,785 612,694<br />

Savings percentage 11.9 9.2 27.3<br />

CONCLUSIONS<br />

• The energy analysis of the El Arenal drinking water production system equipment<br />

and installations showed that the general conditions of these old installations (with<br />

some motor changes) varies from average to bad, as evidenced through low<br />

efficiencies, mainly in pumps (see Actions Matrix: Diagnostic of Installations).<br />

• The analysis of potential improvements, shown in Table ES-1: Identified Energysaving<br />

Measures and Potential demand, energy and cost Savings, identified a number