ELECTRIC MOTOR DESIGN Page 1 of 11 Motor Design 2008/12/22 ...

ELECTRIC MOTOR DESIGN Page 1 of 11 Motor Design 2008/12/22 ...

ELECTRIC MOTOR DESIGN Page 1 of 11 Motor Design 2008/12/22 ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

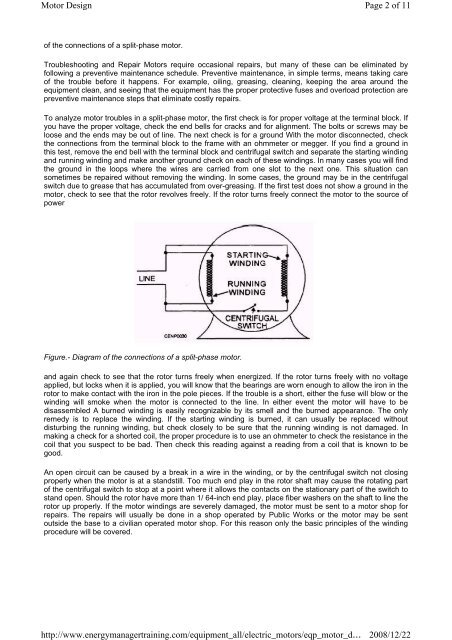

<strong>Motor</strong> <strong>Design</strong>http://www.energymanagertraining.com/equipment_all/electric_motors/eqp_motor_d...<strong>Page</strong> 2 <strong>of</strong> <strong>11</strong><strong>2008</strong>/<strong>12</strong>/<strong>22</strong><strong>of</strong> the connections <strong>of</strong> a split-phase motor.Troubleshooting and Repair <strong>Motor</strong>s require occasional repairs, but many <strong>of</strong> these can be eliminated byfollowing a preventive maintenance schedule. Preventive maintenance, in simple terms, means taking care<strong>of</strong> the trouble before it happens. For example, oiling, greasing, cleaning, keeping the area around theequipment clean, and seeing that the equipment has the proper protective fuses and overload protection arepreventive maintenance steps that eliminate costly repairs.To analyze motor troubles in a split-phase motor, the first check is for proper voltage at the terminal block. Ifyou have the proper voltage, check the end bells for cracks and for alignment. The bolts or screws may beloose and the ends may be out <strong>of</strong> line. The next check is for a ground With the motor disconnected, checkthe connections from the terminal block to the frame with an ohmmeter or megger. If you find a ground inthis test, remove the end bell with the terminal block and centrifugal switch and separate the starting windingand running winding and make another ground check on each <strong>of</strong> these windings. In many cases you will findthe ground in the loops where the wires are carried from one slot to the next one. This situation cansometimes be repaired without removing the winding. In some cases, the ground may be in the centrifugalswitch due to grease that has accumulated from over-greasing. If the first test does not show a ground in themotor, check to see that the rotor revolves freely. If the rotor turns freely connect the motor to the source <strong>of</strong>powerFigure.- Diagram <strong>of</strong> the connections <strong>of</strong> a split-phase motor.and again check to see that the rotor turns freely when energized. If the rotor turns freely with no voltageapplied, but locks when it is applied, you will know that the bearings are worn enough to allow the iron in therotor to make contact with the iron in the pole pieces. If the trouble is a short, either the fuse will blow or thewinding will smoke when the motor is connected to the line. In either event the motor will have to bedisassembled A burned winding is easily recognizable by its smell and the burned appearance. The onlyremedy is to replace the winding. If the starting winding is burned, it can usually be replaced withoutdisturbing the running winding, but check closely to be sure that the running winding is not damaged. Inmaking a check for a shorted coil, the proper procedure is to use an ohmmeter to check the resistance in thecoil that you suspect to be bad. Then check this reading against a reading from a coil that is known to begood.An open circuit can be caused by a break in a wire in the winding, or by the centrifugal switch not closingproperly when the motor is at a standstill. Too much end play in the rotor shaft may cause the rotating part<strong>of</strong> the centrifugal switch to stop at a point where it allows the contacts on the stationary part <strong>of</strong> the switch tostand open. Should the rotor have more than 1/ 64-inch end play, place fiber washers on the shaft to line therotor up properly. If the motor windings are severely damaged, the motor must be sent to a motor shop forrepairs. The repairs will usually be done in a shop operated by Public Works or the motor may be sentoutside the base to a civilian operated motor shop. For this reason only the basic principles <strong>of</strong> the windingprocedure will be covered.