Protectosil® CHEM-TRETE® 40 D

Protectosil® CHEM-TRETE® 40 D

Protectosil® CHEM-TRETE® 40 D

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

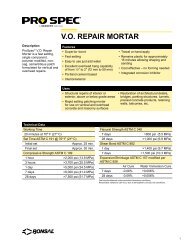

TECHNICAL DATAProtectosil <strong>CHEM</strong>-TRETE <strong>40</strong> D is a clear, colorless liquidcontaining <strong>40</strong>% isobutyltrialkoxysilane and ethyl silicatein alcohol.ColorActive Substancewater whiteisobutyltrialkoxysilaneethyl silicateActive Content <strong>40</strong>% by weightSolventdenatured ethyl alcoholFlash Point 54°FDensity7.0 lb/galTEST DATAASTM C 97“Absorption of Natural Building Stone”83% effective in reducing water absorptionASTM C 88“Sulfate Soundness Test”No weight loss after treatmentFederal Specification SSW-110C“Breathability of Coatings”98.5% moisture vapor transmissionASTM C 67“Testing Bricks for Absorption”92% effective in reducing water intrusionINSTALLATIONConcrete must be allowed to cure for a minimum of 28 days.All repointing must be completed and allowed to cure for atleast 3 days. Concrete repair and replacement must becompleted prior to application of Protectosil <strong>CHEM</strong>-TRETE<strong>40</strong> D. Patching materials, caulking, sealing materials andtraffic paint must be fully cured before applying Protectosil<strong>CHEM</strong>-TRETE <strong>40</strong> D.All surfaces must be cleaned to remove all traces of dirt,dust, efflorescence, mold, salt, grease, oil, asphalt, laitance,curing compounds, paint, coatings and other foreignmaterials. Acceptable surface cleaning methods includeshotblasting, sandblasting, waterblasting and using chemicalcleaners. Check with your Protectosil representative toverify that surface preparation is adequate.Protectosil <strong>CHEM</strong>-TRETE <strong>40</strong> D should be applied usinglow-pressure (15 to 25 psi) pumping equipment with a wetfan type spray nozzle. Alternate methods include usingeither a power roller with a 1" nap or a brush. Do not alter ordilute the material. Do not apply to a wet or damp substrate.A test patch should be applied to the substrate to verifycoverage rate, desired results and application conditions.On vertical surfaces, apply Protectosil <strong>CHEM</strong>-TRETE <strong>40</strong> Din a flooding application from the bottom up, so the materialruns down 6 to 8 inches below the spray pattern. Coveragerates on limestone surfaces are between 75 and 125 ft 2 /gal.Multiple applications may be needed for denser consolidation.Surfaces such as polished marble may have higher coverage rates.For warranty qualification, your Protectosil representative cangive an exact coverage rate for your particular project. Pleaserefer to the “Protectosil <strong>CHEM</strong>-TRETE <strong>40</strong> D ApplicationInstructions” for more detailed information.Precautions: Protectosil <strong>CHEM</strong>-TRETE <strong>40</strong> D is aflammable liquid and should be kept away from heat, sparks,open flame and other sources of ignition. Protectosil<strong>CHEM</strong>-TRETE <strong>40</strong> D containers should be kept closed whennot in use and should be stored at temperatures between0°F (-20°C) and 120°F (50°C), away from rain and standingwater. When working in an enclosed area, an air respiratorshould be used. Please refer to the material safety data sheetfor more detailed information.AVAILABILITYProtectosil <strong>CHEM</strong>-TRETE <strong>40</strong> D is available in 5- and55-gallon drums to approved applicators, F.O.B. to variouswarehouses throughout the United States. Contact EvonikDegussa Corporation at 1 (800) 828-0919 for the salesrepresentative in your area to get specific cost information.TECHNICAL SERVICETechnical service engineers and chemists are available toanswer questions about product performance, applicationmethods and compatibility with other building materials.For more information, MSDS and the most updated product information, and to find your local representative, go to www.protectosil.com.Protectosil ® , <strong>CHEM</strong>-TRETE ® = registered trademarks of Evonik Industries.This information and all technical and other advice are based on Evonik Degussa Corp's ("Evonik") present knowledge and experience. However, Evonik assumesno liability for such information or advice, including the extent to which such information or advice may relate to third party intellectual property rights. Evonikreserves the right to make any changes to information or advice at any time, without prior or subsequent notice. EVONIK DISCLAIMS ALL REPRESENTATIONSAND WARRANTIES, WHETHER EXPRESS OR IMPLIED, AND SHALL HAVE NO LIABILITY FOR, MERCHANTABILITY OF THE PRODUCT OR ITS FITNESSFOR A PARTICULAR PURPOSE (EVEN IF EVONIK IS AWARE OF SUCH PURPOSE), OR OTHERWISE. EVONIK SHALL NOT BE RESPONSIBLE FORCONSEQUENTIAL, INDIRECT OR INCIDENTAL DAMAGES (INCLUDING LOSS OF PROFITS) OF ANY KIND. It is the customer's sole responsibility andobligation to arrange for inspection and testing of all products by qualified experts. Reference to trade names used by other companies is neither a recommendationnor an endorsement of the corresponding product, and does not imply that similar products could not be used.

![sheets/Data sheetsVB6_Spec[1].pdf - Sweeney Materials](https://img.yumpu.com/38180404/1/190x245/sheets-data-sheetsvb6-spec1pdf-sweeney-materials.jpg?quality=85)