GUNS Magazine December 1955 - Jeffersonian's Home Page

GUNS Magazine December 1955 - Jeffersonian's Home Page

GUNS Magazine December 1955 - Jeffersonian's Home Page

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

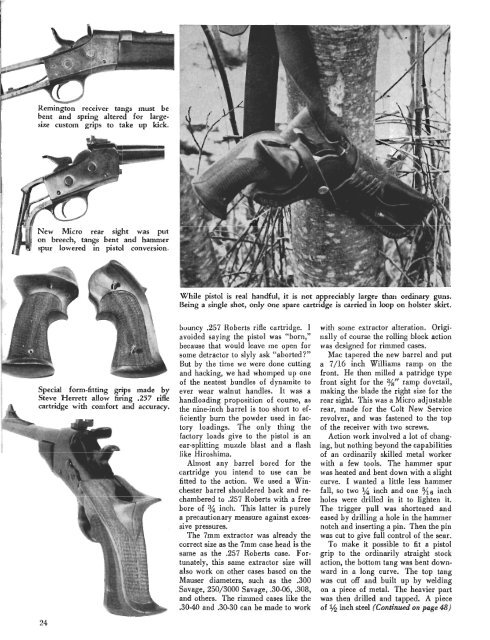

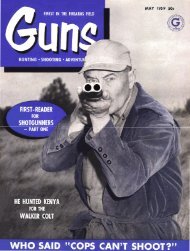

Remington receiver tangs must bebent and spring altered for largesizecustom grips to take up kick.New Micro rear sight was puton breech, tangs bent and hammerspur lowered in pistol conversion.While pistol is real handful, it is not appreciably larger than ordinary guns.Being a single shot, only one spare cartridge is carried in loop on holster skirt.Special form-fitting grips made bySteve Herrett allow firins .257 riflebouncy .257 Roberts rifle cartridge. 1avoided saying the pistol was "born,"because that would leave me open forsome detractor to slyly ask "aborted?"But by the time we were done cuttingand hacking, we had whomped up oneof the neatest bundles of dynamite toever wear walnut handles. It was ahandloading proposition of course, asthe nine-inch barrel is too short to efficientlyburn the powder used in factoryloadings. The only thing thefactory loads give to the pistol is anear-splitting muzzle blast and a flashlike Hiroshima.Almost any barrel bored for thecartridge you intend to use can befitted to the action. We used a Winchesterbarrel shouldered back and rechamberedto .257 Roberts with a freebore of % inch. This latter is purelya precautionary measure against excessivepressures.The 7mm extractor was already thecorrect size as the 7mm case head is thesame as the .257 Roberts case. Fortunately,this same extractor size willalso work on other cases based on theMauser diameters, such as the .300Savage, 250/3000 Savage, .30-06, .308,and others. The rimmed cases like the.30-40 and .30-30 can be made to workwith some extractor alteration. Originallyof course the rolling block actionwas designed for rimmed cases.Mac tapered the new barrel and puta 7/16 inch Williams ramp on thefront. He then milled a patridge typefront sight for theramp dovetail,making the blade the right size for therear sight. This was a Micro adjustablerear, made for the Colt New Servicerevolver, and was fastened to the topof the receiver with two screws.Action work involved a lot of changing,but nothing beyond the capabilitiesof an ordinarily skilled metal workerwith a few tools. The hammer spurwas heated and bent down with a slightcurve. I wanted a little less hammerfall, so two VA, inch and one ^Aa inchholes were drilled in it to lighten it.The trigger pull was shortened andeased by drilling a hole in the hammernotch and inserting a pin. Then the pinwas cut to give full control of the sear.To make it possible to fit a pistolgrip to the ordinarily straight stockaction, the bottom tang was bent downwardin a long curve. The top tangwas cut off and built up by weldingon a piece of metal. The heavier partwas then drilled and tapped. A pieceof % inch steel (Continued on page 48)