Wetstock Reconciliation at fuel storage facilities - Carrickfergus ...

Wetstock Reconciliation at fuel storage facilities - Carrickfergus ...

Wetstock Reconciliation at fuel storage facilities - Carrickfergus ...

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

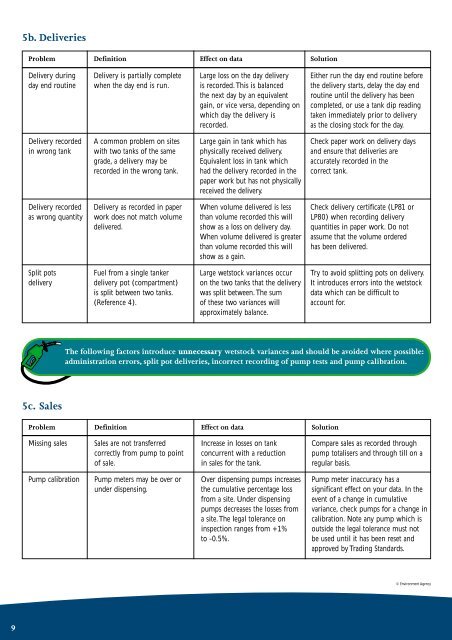

5b. DeliveriesProblem Definition Effect on d<strong>at</strong>a SolutionDelivery during Delivery is partially complete Large loss on the day delivery Either run the day end routine beforeday end routine when the day end is run. is recorded. This is balanced the delivery starts, delay the day endthe next day by an equivalent routine until the delivery has beengain, or vice versa, depending on completed, or use a tank dip readingwhich day the delivery is taken immedi<strong>at</strong>ely prior to deliveryrecorded.as the closing stock for the day.Delivery recorded A common problem on sites Large gain in tank which has Check paper work on delivery daysin wrong tank with two tanks of the same physically received delivery. and ensure th<strong>at</strong> deliveries aregrade, a delivery may be Equivalent loss in tank which accur<strong>at</strong>ely recorded in therecorded in the wrong tank. had the delivery recorded in the correct tank.paper work but has not physicallyreceived the delivery.Delivery recorded Delivery as recorded in paper When volume delivered is less Check delivery certific<strong>at</strong>e (LP81 oras wrong quantity work does not m<strong>at</strong>ch volume than volume recorded this will LP80) when recording deliverydelivered. show as a loss on delivery day. quantities in paper work. Do notWhen volume delivered is gre<strong>at</strong>er assume th<strong>at</strong> the volume orderedthan volume recorded this will has been delivered.show as a gain.Split pots Fuel from a single tanker Large wetstock variances occur Try to avoid splitting pots on delivery.delivery delivery pot (compartment) on the two tanks th<strong>at</strong> the delivery It introduces errors into the wetstockis split between two tanks. was split between. The sum d<strong>at</strong>a which can be difficult to(Reference 4). of these two variances will account for.approxim<strong>at</strong>ely balance.The following factors introduce unnecessary wetstock variances and should be avoided where possible:administr<strong>at</strong>ion errors, split pot deliveries, incorrect recording of pump tests and pump calibr<strong>at</strong>ion.5c. SalesProblem Definition Effect on d<strong>at</strong>a SolutionMissing sales Sales are not transferred Increase in losses on tank Compare sales as recorded throughcorrectly from pump to point concurrent with a reduction pump totalisers and through till on aof sale. in sales for the tank. regular basis.Pump calibr<strong>at</strong>ion Pump meters may be over or Over dispensing pumps increases Pump meter inaccuracy has aunder dispensing. the cumul<strong>at</strong>ive percentage loss significant effect on your d<strong>at</strong>a. In thefrom a site. Under dispensing event of a change in cumul<strong>at</strong>ivepumps decreases the losses from variance, check pumps for a change ina site. The legal tolerance on calibr<strong>at</strong>ion. Note any pump which isinspection ranges from +1% outside the legal tolerance must notto -0.5%.be used until it has been reset andapproved by Trading Standards.© Environment Agency9