Facts worth knowing about Oil nozzles - Danfoss.com

Facts worth knowing about Oil nozzles - Danfoss.com

Facts worth knowing about Oil nozzles - Danfoss.com

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

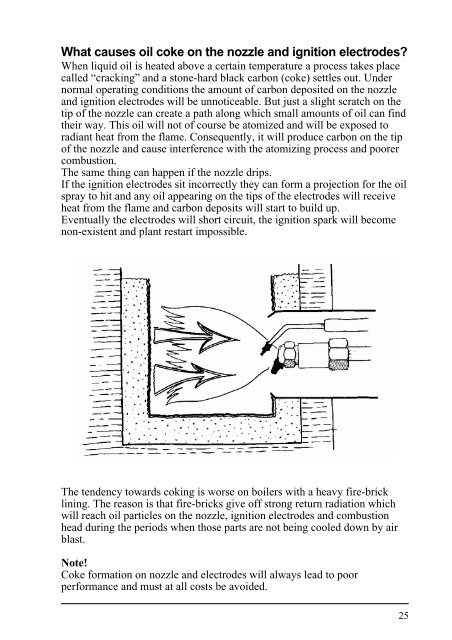

What causes oil coke on the nozzle and ignition electrodes?When liquid oil is heated above a certain temperature a process takes placecalled “cracking” and a stone-hard black carbon (coke) settles out. Undernormal operating conditions the amount of carbon deposited on the nozzleand ignition electrodes will be unnoticeable. But just a slight scratch on thetip of the nozzle can create a path along which small amounts of oil can findtheir way. This oil will not of course be atomized and will be exposed toradiant heat from the flame. Consequently, it will produce carbon on the tipof the nozzle and cause interference with the atomizing process and poorer<strong>com</strong>bustion.The same thing can happen if the nozzle drips.If the ignition electrodes sit incorrectly they can form a projection for the oilspray to hit and any oil appearing on the tips of the electrodes will receiveheat from the flame and carbon deposits will start to build up.Eventually the electrodes will short circuit, the ignition spark will be<strong>com</strong>enon-existent and plant restart impossible.The tendency towards coking is worse on boilers with a heavy fire-bricklining. The reason is that fire-bricks give off strong return radiation whichwill reach oil particles on the nozzle, ignition electrodes and <strong>com</strong>bustionhead during the periods when those parts are not being cooled down by airblast.Note!Coke formation on nozzle and electrodes will always lead to poorperformance and must at all costs be avoided.25