HEMPADUR EM 35740 - Hempel

HEMPADUR EM 35740 - Hempel

HEMPADUR EM 35740 - Hempel

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

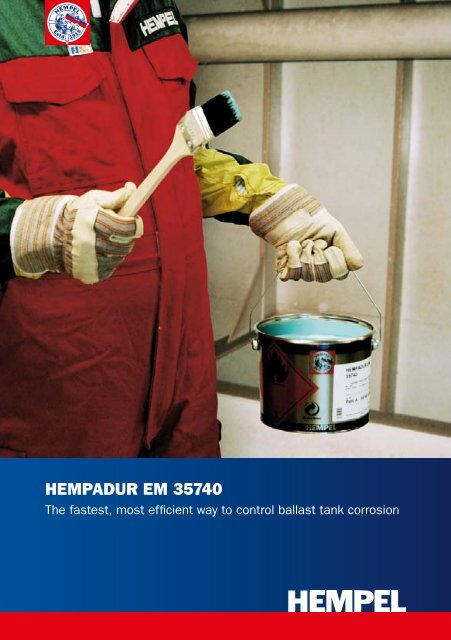

<strong>H<strong>EM</strong>PADUR</strong> <strong>EM</strong> <strong>35740</strong>The fastest, most efficient way to control ballast tank corrosion

Controlling corrosion in ballasttanks just got a whole lot easier<strong>H<strong>EM</strong>PADUR</strong> Easy Maintenance (<strong>EM</strong> <strong>35740</strong>) makes the tediouswork of controlling corrosion in ballast tanks faster and easierTaking chances with ballast tank corrosion is never a good idea, as minor corrosionspots can quickly grow into major problems that can require drydocking to repair.Today, the need to prevent corrosion from getting the upper hand is even more urgent,as the IMO’s new guidelines for maintenance and repair of ballast tank coatings(MSC.1/Circ.1330) call for costly annual inspections and potentially drydocking torepair if ballast tank corrosion is too severe.Still, keeping corrosion down has been costly and cumbersome, leading many operatorsto postpone maintenance and repair until the ship is scheduled for drydocking.DAMPTOLERANTfastRE-ImmersionLOWVOCEasyapplicationhandybucketPrevention is the best cure<strong>H<strong>EM</strong>PADUR</strong> <strong>EM</strong> <strong>35740</strong> changes all that by providing an effective, easy-to-use solutionfor controlling corrosion at sea. Available in easy-to-handle and waste-reducing 2.5 litrecans, <strong>H<strong>EM</strong>PADUR</strong> <strong>EM</strong> <strong>35740</strong> is easily applied e.g. with brush while your vessel is stillat sea. Special moisture-resistance properties mean you can apply the paint in dampenvironments. And the coating’s fast-curing formula enables re-immersion in just eighthours, with continued curing after immersion. What’s more, <strong>H<strong>EM</strong>PADUR</strong> <strong>EM</strong> <strong>35740</strong> isan exceptionally low VOC coating that protects your crew’s health and the environment.Ballast tanks and beyond<strong>H<strong>EM</strong>PADUR</strong> <strong>EM</strong> <strong>35740</strong> is intended primarily for maintenance of ballast tanks, but isan excellent solution anywhere corrosion spots are a problem. Hempadur <strong>EM</strong> <strong>35740</strong>is an especially advantageous coating in dampness-prone and hard-to-reach areas.Major advantages• The easiest way to keep corrosion down while at sea• Helps keep your ballast tank coating in “GOOD” condition(according to IMO guidelines)• Reduced need for repair work at next drydocking• Short drying/curing time (immersion-ready in eight hours, at 20° Celsius)• Easy handling and less waste, thanks to handy 2.5 litre cans• Easy application using a brush• Surface-tolerant for reduced preparation time• Moisture-tolerant for application on damp surfaces• Extremely low VOC for maximum convenience and care for crew and environment• Minimal PPE (personal protection equipment) required

01/2011H<strong>EM</strong>PEL was founded in 1915 and is today one of the world’s leadingsuppliers of marine and industrial paints. Our 3,600 employees work from 3main and 5 regional Research and Development centres, and 21 productionplants situated in strategic locations across six continents. Our global salesand service organisation operates from more than 150 stock points in over80 countries, providing our customers with expert assistance at all stages ofthe contract.The <strong>Hempel</strong> Group Head Office<strong>Hempel</strong> A/SLundtoftevej 150DK-2800 Kgs. LyngbyDenmarkPhone: +45 4593 3800Fax: +45 4588 5518Email: marine@hempel.comwww.hempel.com