Nickel Metal Hydride Technical Handbook - Gold Peak Industries

Nickel Metal Hydride Technical Handbook - Gold Peak Industries

Nickel Metal Hydride Technical Handbook - Gold Peak Industries

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

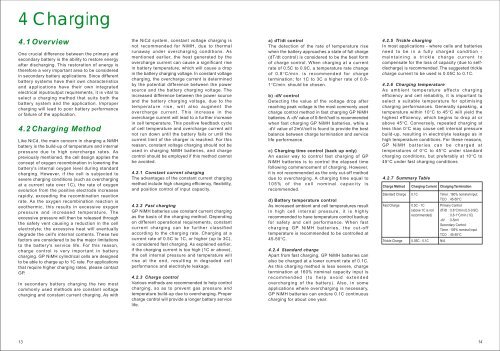

4 Charging4.1OverviewOne crucial difference between the primary andsecondary battery is the ability to restore energyafter discharging. This restoration of energy istherefore a very important area to be consideredin secondary battery applications. Since differentbattery systems have their own characteristicsand applications have their own integratedelectrical input/output requirements, it is vital toselect a charging method that suits both thebattery system and the application. Impropercharging will lead to poor battery performanceor failure of the application.4.2Charging MethodLike NiCd, the main concern in charging a NiMHbattery is the build-up of temperature and internalpressure due to high overcharge rates. Aspreviously mentioned, the cell design applies theconcept of oxygen recombination in lowering thebattery's internal oxygen level during standardcharging. However, if the cell is subjected tosevere charging conditions (such as overchargingat a current rate over 1C), the rate of oxygenevolution from the positive electrode increasesrapidly, exceeding the recombination reactionrate. As the oxygen recombination reaction isexothermic, this results in excessive oxygenpressure and increased temperature. Theexcessive pressure will then be released throughthe safety vent causing a reduction in the cellelectrolyte; the excessive heat will eventuallydegrade the cell's internal contents. These twofactors are considered to be the major limitationsto the battery's service life. For this reason,charge control is very important in batterycharging. GP NiMH cylindrical cells are designedto be able to charge up to 1C rate. For applicationsthat require higher charging rates, please contactGP.In secondary battery charging the two mostcommonly used methods are constant voltagecharging and constant current charging. As withthe NiCd system, constant voltage charging isnot recommended for NiMH, due to thermalrunaway under overcharging conditions. Asmentioned earlier, the heat generated by theovercharge current can cause a significant risein battery temperature, which will cause a dropin the battery charging voltage. In constant voltagecharging, the overcharge current is determinedby the potential difference between the powersource and the battery charging voltage. Theincreased difference between the power sourceand the battery charging voltage, due to thetemperature rise, will also augment theovercharge current. This increase in theovercharge current will lead to a further increasein cell temperature. This positive feedback cycleof cell temperature and overcharge current willnot run down until the battery fails or until thecurrent limit of the charger is reached. For thisreason, constant voltage charging should not beused in charging NiMH batteries, and chargecontrol should be employed if this method cannotbe avoided.4.2.1 Constant current chargingThe advantages of the constant current chargingmethod include high charging efficiency, flexibility,and position control of input capacity.4.2.2 Fast chargingGP NiMH batteries use constant current chargingas the basis of the charging method. Dependingon different operational requirements, constantcurrent charging can be further classifiedaccording to the charging rate. Charging at acurrent rate of 0.5C to 1C, or higher (up to 3C),is considered fast charging. As explained earlier,if the charging current is too high (1C or above),the cell internal pressure and temperature willrise at the end, resulting in degraded cellperformance and electrolyte leakage.4.2.3 Charge controlVarious methods are recommended to help controlcharging, so as to prevent gas pressure andtemperature build-up due to overcharging. Propercharge control will provide a longer battery servicelife.a) dT/dt controlThe detection of the rate of temperature risewhen the battery approaches a state of full charge(dT/dt control) is considered to be the best formof charge control. When charging at a currentrate of 0.5C to 0.9C, a temperature rate changeof 0.8°C/min. is recommended for chargetermination; for 1C to 3C a higher rate of 0.8-1°C/min. should be chosen.b) -dV controlDetecting the value of the voltage drop afterreaching peak voltage is the most commonly usedcharge control method in fast charging GP NiMHbatteries. A -dV value of 0-5mV/cell is recommendedwhen fast charging GP NiMH batteries, while a-dV value of 2mV/cell is found to provide the bestbalance between charge termination and servicelife performance.c) Charging time control (back up only)An easier way to control fast charging of GPNiMH batteries is to control the elapsed timefollowing commencement of charging. However,it is not recommended as the only cut-off methoddue to overcharging. A charging time equal to105% of the cell nominal capacity isrecommended.d) Battery temperature controlAs increased ambient and cell temperatures resultin high cell internal pressure, it is highlyrecommended to have temperature control backupfor safety and cell performance. When fastcharging GP NiMH batteries, the cut-offtemperature is recommended to be controlled at45-50°C.4.2.4 Standard chargeApart from fast charging, GP NiMH batteries canalso be charged at a lower current rate of 0.1C.As this charging method is less severe, chargetermination at 160% nominal capacity input isrecommended (to help avoid extendedovercharging of the battery). Also, in someapplications where overcharging is necessary,GP NiMH batteries can endure 0.1C continuouscharging for about one year.4.2.5 Trickle chargingIn most applications - where cells and batteriesneed to be in a fully charged condition -maintaining a trickle charge current tocompensate for the loss of capacity (due to selfdischarge)is recommended. The suggested tricklecharge current to be used is 0.05C to 0.1C.4.2.6 Charging temperatureAs ambient temperature affects chargingefficiency and cell reliability, it is important toselect a suitable temperature for optimisingcharging performances. Generally speaking, atemperature within 10°C to 45°C will yield thehighest efficiency, which begins to drop at orabove 45°C. Conversely, repeated charging atless than 0°C may cause cell internal pressurebuild-up, resulting in electrolyte leakage as inhigh temperature conditions. For these reasons,GP NiMH batteries can be charged attemperatures of 0°C to 45°C under standardcharging conditions, but preferably at 10°C to45°C under fast charging conditions4.2.7 Summary TableCharge Method Charging Current Charging TerminationStandard Charge 0.1C Timer : 160% nominal input;TCO : 45-50°CFast Charge 0.5C - 1C Primary Control:(above 1C is not dT/dt : 0.8°C/min (0.5-0.9C)recommended): 0.8-1°C/min (1C)-dV : 0-5mVSecondary Control:Timer : 105% nominal inputTCO : 45-50°CTrickle Charge 0.05C - 0.1C N/A13 14