Top Notch Grooving Lathe 4010

Top Notch Grooving Lathe 4010

Top Notch Grooving Lathe 4010

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

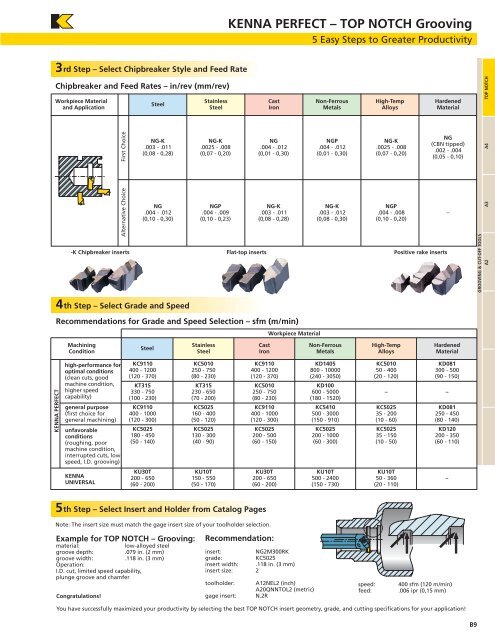

KENNA PERFECT – TOP NOTCH <strong>Grooving</strong>5 Easy Steps to Greater Productivity3rd Step – Select Chipbreaker Style and Feed RateChipbreaker and Feed Rates – in/rev (mm/rev)Workpiece Materialand ApplicationAlternative Choice First ChoiceSteelNG-K.003 - .011(0,08 - 0,28)NG.004 - .012(0,10 - 0,30)StainlessSteelNG-K.0025 - .008(0,07 - 0,20)NGP.004 - .009(0,10 - 0,23)-K Chipbreaker inserts Flat-top inserts Positive rake insertsCastIronNG.004 - .012(0,01 - 0,30)NG-K.003 - .011(0,08 - 0,28)Non-FerrousMetalsNGP.004 - .012(0,01 - 0,30)NG-K.003 - .012(0,08 - 0,30)High-TempAlloysNG-K.0025 - .008(0,07 - 0,20)NGP.004 - .008(0,10 - 0,20)HardenedMaterialNG(CBN tipped).002 - .004(0,05 - 0,10)–GROOVING & CUT-OFF TOOLSA2 A3 A4 TOP NOTCH4th Step – Select Grade and SpeedRecommendations for Grade and Speed Selection – sfm (m/min)Workpiece MaterialMachiningConditionSteelStainlessSteelCastIronNon-FerrousMetalsHigh-TempAlloysHardenedMaterialKENNA PERFECThigh-performance foroptimal conditions(clean cuts, goodmachine condition,higher speedcapability)general purpose(first choice forgeneral machining)unfavorableconditions(roughing, poormachine condition,interrupted cuts, lowspeed, I.D. grooving)KC9110400 - 1200(120 - 370)KT315330 - 750(100 - 230)KC9110400 - 1000(120 - 300)KC5025180 - 450(50 - 140)KC5010250 - 750(80 - 230)KT315230 - 650(70 - 200)KC5025160 - 400(50 - 120)KC5025130 - 300(40 - 90)KC9110400 - 1200(120 - 370)KC5010250 - 750(80 - 230)KC9110400 - 1000(120 - 300)KC5025200 - 500(60 - 150)KD1405800 - 10000(240 - 3050)KD100600 - 5000(180 - 1520)KC5410500 - 3000(150 - 910)KC5025200 - 1000(60 - 300)KC501050 - 400(20 - 120)KD081300 - 500(90 - 150)– –KC502535 - 200(10 - 60)KC502535 - 150(10 - 50)KD081250 - 450(80 - 140)KD120200 - 350(60 - 110)KENNAUNIVERSALKU30T200 - 650(60 - 200)KU10T150 - 550(50 - 170)KU30T200 - 650(60 - 200)KU10T500 - 2400(150 - 730)KU10T50 - 360(20 - 110)–5th Step – Select Insert and Holder from Catalog PagesNote: The insert size must match the gage insert size of your toolholder selection.Example for TOP NOTCH – <strong>Grooving</strong>:material:low-alloyed steelgroove depth:.079 in. (2 mm)groove width:.118 in. (3 mm)Operation:I.D. cut, limited speed capability,plunge groove and chamferCongratulations!Recommendation:insert:NG2M300RKgrade:KC5025insert width: .118 in. (3 mm)insert size: 2toolholder: A12NEL2 (inch)A20QNNTOL2 (metric)gage insert: N.2Rspeed:feed:400 sfm (120 m/min).006 ipr (0,15 mm)You have successfully maximized your productivity by selecting the best TOP NOTCH insert geometry, grade, and cutting specifications for your application!B9

![Download PDF [5.61 MB] - Precision Tooling Services Co.,Ltd.](https://img.yumpu.com/39368757/1/190x245/download-pdf-561-mb-precision-tooling-services-coltd.jpg?quality=85)