Layout 1

Layout 1

Layout 1

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

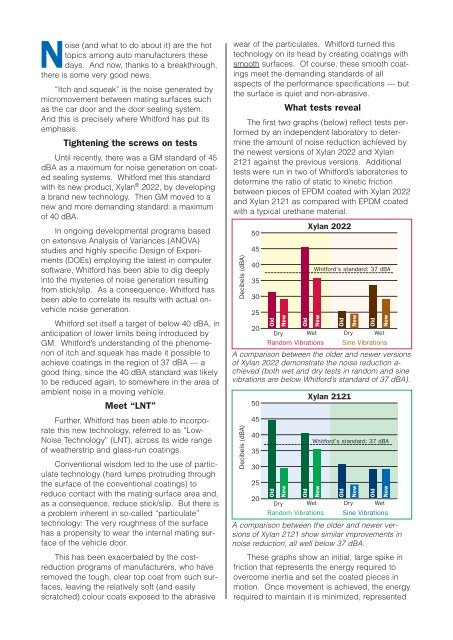

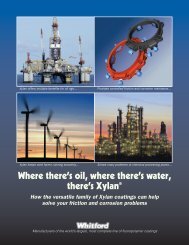

Noise (and what to do about it) are the hottopics among auto manufacturers thesedays. And now, thanks to a breakthrough,there is some very good news.“Itch and squeak” is the noise generated bymicromovement between mating surfaces suchas the car door and the door sealing system.And this is precisely where Whitford has put itsemphasis.Tightening the screws on testsUntil recently, there was a GM standard of 45dBA as a maximum for noise generation on coatedsealing systems. Whitford met this standardwith its new product, Xylan ® 2022, by developinga brand new technology. Then GM moved to anew and more demanding standard: a maximumof 40 dBA.In ongoing developmental programs basedon extensive Analysis of Variances (ANOVA)studies and highly specific Design of Experiments(DOEs) employing the latest in computersoftware, Whitford has been able to dig deeplyinto the mysteries of noise generation resultingfrom stick/slip. As a consequence, Whitford hasbeen able to correlate its results with actual onvehiclenoise generation.Whitford set itself a target of below 40 dBA, inanticipation of lower limits being introduced byGM. Whitford’s understanding of the phenomenonof itch and squeak has made it possible toachieve coatings in the region of 37 dBA — agood thing, since the 40 dBA standard was likelyto be reduced again, to somewhere in the area ofambient noise in a moving vehicle.Meet “LNT”Further, Whitford has been able to incorporatethis new technology, referred to as “Low-Noise Technology” (LNT), across its wide rangeof weatherstrip and glass-run coatings.Conventional wisdom led to the use of particulatetechnology (hard lumps protruding throughthe surface of the conventional coatings) toreduce contact with the mating surface area and,as a consequence, reduce stick/slip. But there isa problem inherent in so-called “particulate”technology: The very roughness of the surfacehas a propensity to wear the internal mating surfaceof the vehicle door.This has been exacerbated by the costreductionprograms of manufacturers, who haveremoved the tough, clear top coat from such surfaces,leaving the relatively soft (and easilyscratched) colour coats exposed to the abrasivewear of the particulates. Whitford turned thistechnology on its head by creating coatings withsmooth surfaces. Of course, these smooth coatingsmeet the demanding standards of allaspects of the performance specifications — butthe surface is quiet and non-abrasive.What tests revealThe first two graphs (below) reflect tests performedby an independent laboratory to determinethe amount of noise reduction achieved bythe newest versions of Xylan 2022 and Xylan2121 against the previous versions. Additionaltests were run in two of Whitford’s laboratories todetermine the ratio of static to kinetic frictionbetween pieces of EPDM coated with Xylan 2022and Xylan 2121 as compared with EPDM coatedwith a typical urethane material.Decibels (dBA)50454035302520OldNewDry WetRandom VibrationsXylan 2022NewDryWetSine VibrationsA comparison between the older and newer versionsof Xylan 2022 demonstrate the noise reduction a-chieved (both wet and dry tests in random and sinevibrations are below Whitford’s standard of 37 dBA).Decibels (dBA)50454035302520OldNewOld OldDry WetRandom VibrationsWhitford’s standard: 37 dBAThese graphs show an initial, large spike infriction that represents the energy required toovercome inertia and set the coated pieces inmotion. Once movement is achieved, the energyrequired to maintain it is minimized, representedOldXylan 2121NewOldDryNewNewOldOldNewWhitford’s standard: 37 dBANewWetSine VibrationsA comparison between the older and newer versionsof Xylan 2121 show similar improvements innoise reduction, all well below 37 dBA.