309641 - Graco Inc.

309641 - Graco Inc.

309641 - Graco Inc.

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

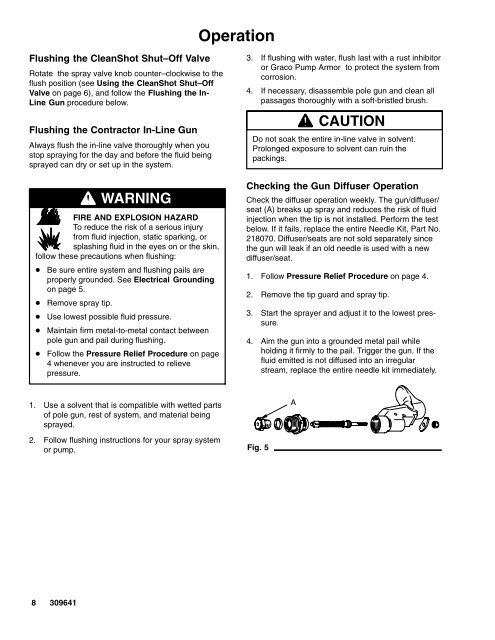

OperationFlushing the CleanShot Shut–Off ValveRotate the spray valve knob counter–clockwise to theflush position (see Using the CleanShot Shut–OffValve on page 6), and follow the Flushing the In-Line Gun procedure below.Flushing the Contractor In-Line GunAlways flush the in-line valve thoroughly when youstop spraying for the day and before the fluid beingsprayed can dry or set up in the system.FIRE AND EXPLOSION HAZARDTo reduce the risk of a serious injuryfrom fluid injection, static sparking, orsplashing fluid in the eyes on or the skin,follow these precautions when flushing:Be sure entire system and flushing pails areproperly grounded. See Electrical Groundingon page 5.Remove spray tip.WARNINGUse lowest possible fluid pressure.Maintain firm metal-to-metal contact betweenpole gun and pail during flushing.Follow the Pressure Relief Procedure on page4 whenever you are instructed to relievepressure.3. If flushing with water, flush last with a rust inhibitoror <strong>Graco</strong> Pump Armor to protect the system fromcorrosion.4. If necessary, disassemble pole gun and clean allpassages thoroughly with a soft-bristled brush.CAUTIONDo not soak the entire in-line valve in solvent.Prolonged exposure to solvent can ruin thepackings.Checking the Gun Diffuser OperationCheck the diffuser operation weekly. The gun/diffuser/seat (A) breaks up spray and reduces the risk of fluidinjection when the tip is not installed. Perform the testbelow. If it fails, replace the entire Needle Kit, Part No.218070. Diffuser/seats are not sold separately sincethe gun will leak if an old needle is used with a newdiffuser/seat.1. Follow Pressure Relief Procedure on page 4.2. Remove the tip guard and spray tip.3. Start the sprayer and adjust it to the lowest pressure.4. Aim the gun into a grounded metal pail whileholding it firmly to the pail. Trigger the gun. If thefluid emitted is not diffused into an irregularstream, replace the entire needle kit immediately.1. Use a solvent that is compatible with wetted partsof pole gun, rest of system, and material beingsprayed.2. Follow flushing instructions for your spray systemor pump.Fig. 5A8 <strong>309641</strong>