Distribution of Eggs and Egg Products Distribution of Eggs (in 2010)

Distribution of Eggs and Egg Products Distribution of Eggs (in 2010)

Distribution of Eggs and Egg Products Distribution of Eggs (in 2010)

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

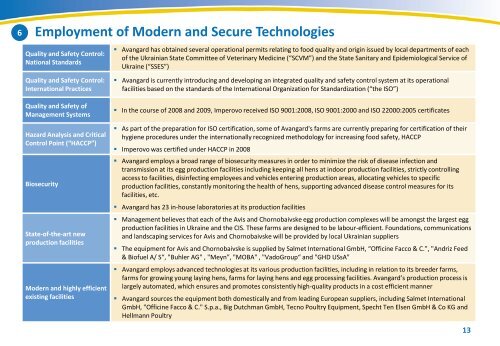

6<br />

Employment <strong>of</strong> Modern <strong>and</strong> Secure Technologies<br />

Quality <strong>and</strong> Safety Control:<br />

National St<strong>and</strong>ards<br />

Quality <strong>and</strong> Safety Control:<br />

International Practices<br />

Quality <strong>and</strong> Safety <strong>of</strong><br />

Management Systems<br />

Hazard Analysis <strong>and</strong> Critical<br />

Control Po<strong>in</strong>t (“HACCP”)<br />

Biosecurity<br />

State-<strong>of</strong>-the-art new<br />

production facilities<br />

Modern <strong>and</strong> highly efficient<br />

exist<strong>in</strong>g facilities<br />

� Avangard has obta<strong>in</strong>ed several operational permits relat<strong>in</strong>g to food quality <strong>and</strong> orig<strong>in</strong> issued by local departments <strong>of</strong> each<br />

<strong>of</strong> the Ukra<strong>in</strong>ian State Committee <strong>of</strong> Veter<strong>in</strong>ary Medic<strong>in</strong>e (“SCVM”) <strong>and</strong> the State Sanitary <strong>and</strong> Epidemiological Service <strong>of</strong><br />

Ukra<strong>in</strong>e (“SSES”)<br />

� Avangard is currently <strong>in</strong>troduc<strong>in</strong>g <strong>and</strong> develop<strong>in</strong>g an <strong>in</strong>tegrated quality <strong>and</strong> safety control system at its operational<br />

facilities based on the st<strong>and</strong>ards <strong>of</strong> the International Organization for St<strong>and</strong>ardization (“the ISO”)<br />

� In the course <strong>of</strong> 2008 <strong>and</strong> 2009, Imperovo received ISO 9001:2008, ISO 9001:2000 <strong>and</strong> ISO 22000:2005 certificates<br />

� As part <strong>of</strong> the preparation for ISO certification, some <strong>of</strong> Avangard's farms are currently prepar<strong>in</strong>g for certification <strong>of</strong> their<br />

hygiene procedures under the <strong>in</strong>ternationally recognized methodology for <strong>in</strong>creas<strong>in</strong>g food safety, HACCP<br />

� Imperovo was certified under HACCP <strong>in</strong> 2008<br />

� Avangard employs a broad range <strong>of</strong> biosecurity measures <strong>in</strong> order to m<strong>in</strong>imize the risk <strong>of</strong> disease <strong>in</strong>fection <strong>and</strong><br />

transmission at its egg production facilities <strong>in</strong>clud<strong>in</strong>g keep<strong>in</strong>g all hens at <strong>in</strong>door production facilities, strictly controll<strong>in</strong>g<br />

access to facilities, dis<strong>in</strong>fect<strong>in</strong>g employees <strong>and</strong> vehicles enter<strong>in</strong>g production areas, allocat<strong>in</strong>g vehicles to specific<br />

production facilities, constantly monitor<strong>in</strong>g the health <strong>of</strong> hens, support<strong>in</strong>g advanced disease control measures for its<br />

facilities, etc.<br />

� Avangard has 23 <strong>in</strong>-house laboratories at its production facilities<br />

� Management believes that each <strong>of</strong> the Avis <strong>and</strong> Chornobaivske egg production complexes will be amongst the largest egg<br />

production facilities <strong>in</strong> Ukra<strong>in</strong>e <strong>and</strong> the CIS. These farms are designed to be labour-efficient. Foundations, communications<br />

<strong>and</strong> l<strong>and</strong>scap<strong>in</strong>g services for Avis <strong>and</strong> Chornobaivske will be provided by local Ukra<strong>in</strong>ian suppliers<br />

� The equipment for Avis <strong>and</strong> Chornobaivske is supplied by Salmet International GmbH, “Offic<strong>in</strong>e Facco & C.”, "Andriz Feed<br />

& Bi<strong>of</strong>uel A/ S“, "Buhler AG" , "Meyn”, "MOBA" , "VadoGroup“ <strong>and</strong> "GHD USsA"<br />

� Avangard employs advanced technologies at its various production facilities, <strong>in</strong>clud<strong>in</strong>g <strong>in</strong> relation to its breeder farms,<br />

farms for grow<strong>in</strong>g young lay<strong>in</strong>g hens, farms for lay<strong>in</strong>g hens <strong>and</strong> egg process<strong>in</strong>g facilities. Avangard’s production process is<br />

largely automated, which ensures <strong>and</strong> promotes consistently high-quality products <strong>in</strong> a cost efficient manner<br />

� Avangard sources the equipment both domestically <strong>and</strong> from lead<strong>in</strong>g European suppliers, <strong>in</strong>clud<strong>in</strong>g Salmet International<br />

GmbH, "Offic<strong>in</strong>e Facco & C." S.p.a., Big Dutchman GmbH, Tecno Poultry Equipment, Specht Ten Elsen GmbH & Co KG <strong>and</strong><br />

Hellmann Poultry<br />

13