Spin-X UF Concentrator Selection and Use Guide - Corning ...

Spin-X UF Concentrator Selection and Use Guide - Corning ...

Spin-X UF Concentrator Selection and Use Guide - Corning ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

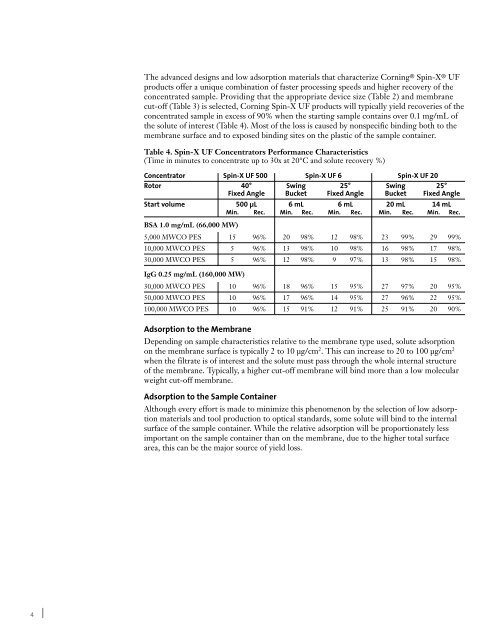

The advanced designs <strong>and</strong> low adsorption materials that characterize <strong>Corning</strong> ® <strong>Spin</strong>-X ® <strong>UF</strong>products offer a unique combination of faster processing speeds <strong>and</strong> higher recovery of theconcentrated sample. Providing that the appropriate device size (Table 2) <strong>and</strong> membranecut-off (Table 3) is selected, <strong>Corning</strong> <strong>Spin</strong>-X <strong>UF</strong> products will typically yield recoveries of theconcentrated sample in excess of 90% when the starting sample contains over 0.1 mg/mL ofthe solute of interest (Table 4). Most of the loss is caused by nonspecific binding both to themembrane surface <strong>and</strong> to exposed binding sites on the plastic of the sample container.Table 4. <strong>Spin</strong>-X <strong>UF</strong> <strong>Concentrator</strong>s Performance Characteristics(Time in minutes to concentrate up to 30x at 20°C <strong>and</strong> solute recovery %)<strong>Concentrator</strong> <strong>Spin</strong>-X <strong>UF</strong> 500 <strong>Spin</strong>-X <strong>UF</strong> 6 <strong>Spin</strong>-X <strong>UF</strong> 20Rotor 40° Swing 25° Swing 25°Fixed Angle Bucket Fixed Angle Bucket Fixed AngleStart volume 500 µL 6 mL 6 mL 20 mL 14 mLMin. Rec. Min. Rec. Min. Rec. Min. Rec. Min. Rec.BSA 1.0 mg/mL (66,000 MW)5,000 MWCO PES 15 96% 20 98% 12 98% 23 99% 29 99%10,000 MWCO PES 5 96% 13 98% 10 98% 16 98% 17 98%30,000 MWCO PES 5 96% 12 98% 9 97% 13 98% 15 98%IgG 0.25 mg/mL (160,000 MW)30,000 MWCO PES 10 96% 18 96% 15 95% 27 97% 20 95%50,000 MWCO PES 10 96% 17 96% 14 95% 27 96% 22 95%100,000 MWCO PES 10 96% 15 91% 12 91% 25 91% 20 90%Adsorption to the MembraneDepending on sample characteristics relative to the membrane type used, solute adsorptionon the membrane surface is typically 2 to 10 µg/cm 2 . This can increase to 20 to 100 µg/cm 2when the filtrate is of interest <strong>and</strong> the solute must pass through the whole internal structureof the membrane. Typically, a higher cut-off membrane will bind more than a low molecularweight cut-off membrane.Adsorption to the Sample ContainerAlthough every effort is made to minimize this phenomenon by the selection of low adsorptionmaterials <strong>and</strong> tool production to optical st<strong>and</strong>ards, some solute will bind to the internalsurface of the sample container. While the relative adsorption will be proportionately lessimportant on the sample container than on the membrane, due to the higher total surfacearea, this can be the major source of yield loss.4