HANSEN TECHNOLOGIES HANSEN TECHNOLOGIES

HANSEN TECHNOLOGIES HANSEN TECHNOLOGIES

HANSEN TECHNOLOGIES HANSEN TECHNOLOGIES

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

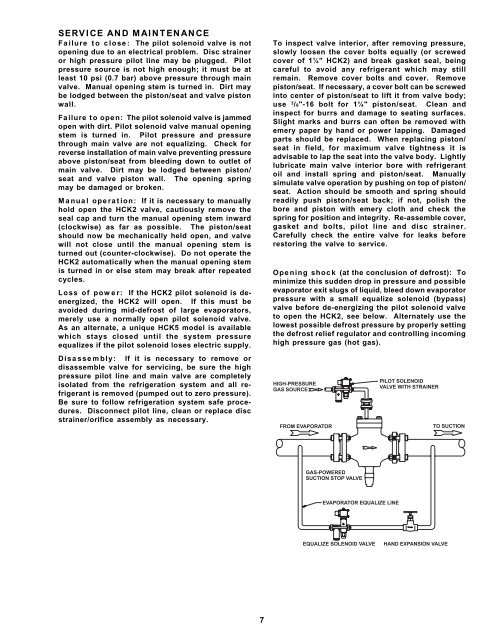

SERVICE AND MAINTENANCEFailure to close: The pilot solenoid valve is notopening due to an electrical problem. Disc straineror high pressure pilot line may be plugged. Pilotpressure source is not high enough; it must be atleast 10 psi (0.7 bar) above pressure through mainvalve. Manual opening stem is turned in. Dirt maybe lodged between the piston/seat and valve pistonwall.Failure to open: The pilot solenoid valve is jammedopen with dirt. Pilot solenoid valve manual openingstem is turned in. Pilot pressure and pressurethrough main valve are not equalizing. Check forreverse installation of main valve preventing pressureabove piston/seat from bleeding down to outlet ofmain valve. Dirt may be lodged between piston/seat and valve piston wall. The opening springmay be damaged or broken.Manual operation: If it is necessary to manuallyhold open the HCK2 valve, cautiously remove theseal cap and turn the manual opening stem inward(clockwise) as far as possible. The piston/seatshould now be mechanically held open, and valvewill not close until the manual opening stem isturned out (counter-clockwise). Do not operate theHCK2 automatically when the manual opening stemis turned in or else stem may break after repeatedcycles.Loss of power: If the HCK2 pilot solenoid is deenergized,the HCK2 will open. If this must beavoided during mid-defrost of large evaporators,merely use a normally open pilot solenoid valve.As an alternate, a unique HCK5 model is availablewhich stays closed until the system pressureequalizes if the pilot solenoid loses electric supply.Disassembly: If it is necessary to remove ordisassemble valve for servicing, be sure the highpressure pilot line and main valve are completelyisolated from the refrigeration system and all refrigerantis removed (pumped out to zero pressure).Be sure to follow refrigeration system safe procedures.Disconnect pilot line, clean or replace discstrainer/orifice assembly as necessary.To inspect valve interior, after removing pressure,slowly loosen the cover bolts equally (or screwedcover of 1¼" HCK2) and break gasket seal, beingcareful to avoid any refrigerant which may stillremain. Remove cover bolts and cover. Removepiston/seat. If necessary, a cover bolt can be screwedinto center of piston/seat to lift it from valve body;use 3 /8"-16 bolt for 1¼" piston/seat. Clean andinspect for burrs and damage to seating surfaces.Slight marks and burrs can often be removed withemery paper by hand or power lapping. Damagedparts should be replaced. When replacing piston/seat in field, for maximum valve tightness it isadvisable to lap the seat into the valve body. Lightlylubricate main valve interior bore with refrigerantoil and install spring and piston/seat. Manuallysimulate valve operation by pushing on top of piston/seat. Action should be smooth and spring shouldreadily push piston/seat back; if not, polish thebore and piston with emery cloth and check thespring for position and integrity. Re-assemble cover,gasket and bolts, pilot line and disc strainer.Carefully check the entire valve for leaks beforerestoring the valve to service.Opening shock (at the conclusion of defrost): Tominimize this sudden drop in pressure and possibleevaporator exit slugs of liquid, bleed down evaporatorpressure with a small equalize solenoid (bypass)valve before de-energizing the pilot solenoid valveto open the HCK2, see below. Alternately use thelowest possible defrost pressure by properly settingthe defrost relief regulator and controlling incominghigh pressure gas (hot gas).7