Round Pack 1250_EN - Guy Machinery

Round Pack 1250_EN - Guy Machinery

Round Pack 1250_EN - Guy Machinery

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

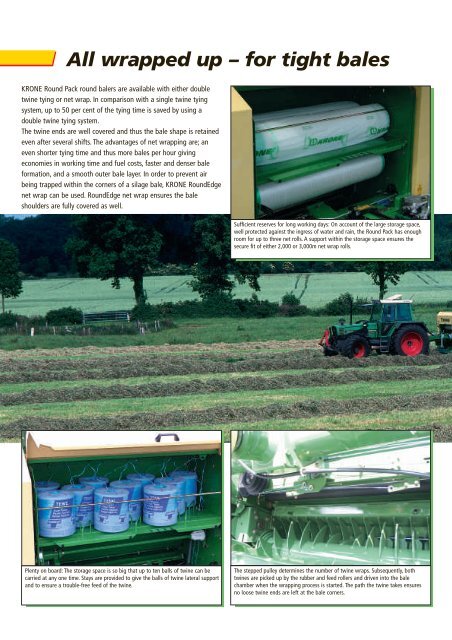

All wrapped up – for tight balesKRONE <strong>Round</strong> <strong>Pack</strong> round balers are available with either doubletwine tying or net wrap. In comparison with a single twine tyingsystem, up to 50 per cent of the tying time is saved by using adouble twine tying system.The twine ends are well covered and thus the bale shape is retainedeven after several shifts. The advantages of net wrapping are; aneven shorter tying time and thus more bales per hour givingeconomies in working time and fuel costs, faster and denser baleformation, and a smooth outer bale layer. In order to prevent airbeing trapped within the corners of a silage bale, KRONE <strong>Round</strong>Edgenet wrap can be used. <strong>Round</strong>Edge net wrap ensures the baleshoulders are fully covered as well.Sufficient reserves for long working days: On account of the large storage space,well protected against the ingress of water and rain, the <strong>Round</strong> <strong>Pack</strong> has enoughroom for up to three net rolls. A support within the storage space ensures thesecure fit of either 2,000 or 3,000m net wrap rolls.Plenty on board: The storage space is so big that up to ten balls of twine can becarried at any one time. Stays are provided to give the balls of twine lateral supportand to ensure a trouble-free feed of the twine.The stepped pulley determines the number of twine wraps. Subsequently, bothtwines are picked up by the rubber and feed rollers and driven into the balechamber when the wrapping process is started. The path the twine takes ensuresno loose twine ends are left at the bale corners.