You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

www.covers.biz

Why choose <strong>Covers</strong><strong>Covers</strong> vision is to be our customers’preferred supplier of timber, buildingand allied materials...We aim to achieve this in various ways...• By building lasting partnerships with you, ourcustomer, meeting your requirements promptly,courteously, efficiently and professionally.• By ensuring that the quality of our service andproducts give us a leading edge in the market.• By maintaining a competitive advantage, embracingleading production and operational methods andinvesting in constructive change.• By supplying a wide range of quality goods, eitherfrom our own stocks or direct from suppliers, atcompetitive prices.• By providing technical advice on all products we supply.• By creating an environment where everyone feelsvalued and experiences job satisfaction throughteamwork and continuing individual development.• By recruiting and retaining the highest quality staff asan equal opportunities provider.To obtain an estimate or to place an order thereare four easy options:1. Visit your local depot.2. Telephone your local depot.3. Fax your request or order to your local depot.4. Email your local depot with your request or order.Please note we accept: MasterCard, Maestro, Switch and Visa cards.Depots details and account information are on the reverse ofthis brochure.2

Our Environmental Policy• Seek to prevent pollution• Seek to minimise waste• Identify and manage environmental risk and hazards• Identify and influence the choice of construction materials and working methods• Plan best practice working• Make better use of the working environment• Make better and efficient use of resources• Set environmental standards• Promote and provide environmental training• Encourage pro active participation in environmental activities• Avoid material waste, water waste, energy waste, vehicle waste, labour waste• The company is committed to an environmental policy and seeks continuousimprovement in performance• In our organisation there is a continuous learning curve• We are FSC ® and PEFC certificated and purchase the majority of our timberfrom approved managed certified forestsPlease recycle3

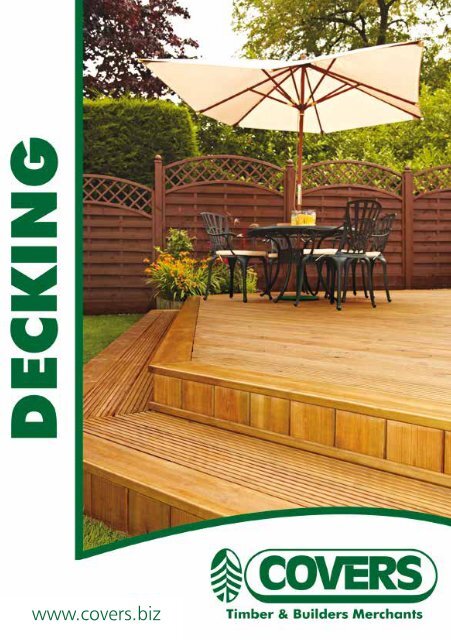

Add that extra dimension to your garden<strong>Decking</strong> creates a natural link between house and garden, making the most of anunder-used but valuable area outdoors.It provides a perfect area for entertaining, barbecues or just relaxing on those long sunnydays. Designed to fit any home and garden, an outdoor deck is a cost effective way tomake extra living space.Enhancing any garden, decking can be enjoyed by everyone in the family and will bedurable, long-lasting, easy to maintain and continue to look good for many years tocome! For a simple ‘patio style’ deck or if you prefer, a more custom designed look,you will find everything you need to create the deck you’ve always wanted with deckingfrom <strong>Covers</strong>.This brochure is an overview of the many variations of decking we have available andwhat decking is best suited to your needs.4

Softwood and Hardwood <strong>Decking</strong>CoverDekDEKThe Complete <strong>Decking</strong> SystemCoverDek is our own branded Softwood and Hardwood decking that is produced in ourmill at Chichester. The CoverDek system we provide includes Baserails, Newells, HandrailsSpindles and Joists.The CoverDek system we have designed will enable the end user to construct a completedeck at an affordable cost.SoftwoodHardwoodNominal Finished Length Code(mm) Dimensions (m)Softwood25 x 100 20 x 94 Per m 61432 x 125 27 x 120 Per m 61538 x 150 33 x 144 Per m 616Hardwood25 x 150 21 x 145 Per m 44299See page 25 for additional parts5

Composite <strong>Decking</strong>FinnForest Composite TMComposite decking provides a natural looking surface that is easy to clean and will lastyear after year. No need to paint, seal, stain or even waterproof.Composite is ideal wherever exceptional durability and weather resistance are required.CompositionMade from 90% recycled hardwood andpolyethylene products, Composite iseco-friendly and long-lasting.‘Secret’ clips and fixings providea flush, fixing free surfaceNominal Finished Length Code(mm) Dimensions (m)25 x 150 21 x 145 3.6 564346

Composite <strong>Decking</strong>UniclassEPICL81215:P511Q13:X52Cl/SfB(90.41) Hi3Millboard Enhanced GrainThe enhanced grain boards create a classic decking area that will complement bothtraditional and contemporary settings. The wood grain finish which is individuallyhand-enhanced, is stylish and durable even in the most demanding of environments.Available in four attractive colours and a choice of widths and lengths.CompositionA blend of reclaimed materials bonded witha hybrid polyurethane polymer and fibres forstrength and durability.spring 2011DriftwoodLimed OakGolden OakCoppered OakNominal Length Code(mm) (m)32 x 146 2.4 N/A32 x 196 2.4 6145732 x 176 3.6 N/AAvailable to orderSee page 25 for additional parts7

Composite <strong>Decking</strong>UniclassEPICL81215:P511Q13:X52Cl/SfB(90.41) Hi3Millboard WeatheredAdding character and style, these charming boards create decking areas of timelessbeauty as they have been made from manufactured moulds created from hand pickedantique oak boards of over 100 years old.Available in two character-full colours, the boards have Lastane anti-slip surfacemaking them not only look good but also safer in wet conditions.CompositionA blend of reclaimed materials bonded spring with 2011a hybrid polyurethane polymer and fibres forstrength and durability.VintageDrifwoodNominal Length Code(mm) (m)32 x 200 3.6 61456See page 25 for additional parts8

Composite <strong>Decking</strong>UniclassEPICL81215:P511Q13:X52Cl/SfB(90.41) Hi3Millboard FlutedTaking inspiration from the classic style of conventional decking but made from low-slipLastane, our fluted boards bring this design right up to date with crisp clean lines thatdefine and enhance the beauty of the oak grain.Available in two attractive colours, fluted is sure to create an eye-catching deck in allsituations.CompositionA blend of reclaimed materials bonded witha hybrid polyurethane polymer and fibres forstrength and durability.spring 2011Coppered OakGolden OakNominal Length(mm) (m)32 x 146 2.4Available to orderSee page 25 for additional parts9

Composite <strong>Decking</strong>UniclassEPICL81215:P511Q13:X52Cl/SfB(90.41) Hi3Millboard Lasta Grip 40 & Last Grip 50For use wherever extra slip resistance is required Lasta Grip 40 and 50 have two integraltextured strips moulded into resilient softer Lastane surface, covering over a third ofthe surface area.Excellent slip resistance is achieved without the risk of personal injury inherent in highlyabrasive sharp grit strips. The non-porous Lastane surface repels moss and needs nomaintenance other than occasional wash down.The surface helps deaden footfall and furniture movement noise, making them theperfect choice for public places, commercial and leisure applications.Compositionspring 2011A blend of reclaimed materials bonded witha hybrid polyurethane polymer and fibres forstrength and durability.Lasta Grip 40 - GoldenLasta Grip 50 - CopperedNominal Length(mm) (m)32 x 146 2.4Available to orderSee page 25 for additional parts10

Composite <strong>Decking</strong>UniclassEPICL81215:P511Q13:X52Cl/SfB(90.41) Hi3Millboard Board-and-end grainThe subtle design of board-and-end grain gives a distinctively different image to anydecking area and is entirely unique in the marketplace.Taken from the finest oak and timber samples, these boards portray the beauty ofcontrasting natural wood characteristics with the end grain, whilst retaining the stabilityand safety that Millboard is renowned for, with the resilient Lastane surface.CompositionA blend of reclaimed materials bonded witha hybrid polyurethane polymer and fibres forstrength and durability.spring 2011Golden OakCoppered OakNominal Length(mm) (m)32 x 146 2.4Available to orderSee page 25 for additional parts11

Composite <strong>Decking</strong>UniclassEPICL81215:P511Q13:X52Cl/SfB(90.41) Hi3Millboard Half WeaveTruly bringing interior design outside, half weave combines the appearance of deckingboards with shorter cross pieces in one board that add the character of parquet flooring.Blending perfectly with most settings, this exclusive design creates a relaxing atmospherethat is perfect for any prestigious outdoor area.Available in two attractive colours, all boards have Lastane resilient, anti-slip surface.CompositionA blend of reclaimed materials bonded witha hybrid polyurethane polymer and fibres forstrength and durability. spring 2011Golden OakCoppered OakNominal Length(mm) (m)32 x 196 2.4Available to orderSee page 25 for additional parts12

Composite <strong>Decking</strong>MAINE Dwood compW.Howard Maine Deck Wood CompositeMAINE DECKwood compositePrimer Mould +Plus Maine Deck boards are profiled and then allowed to air cool whichAvailable ex-Stock...means they will not twist or warp.Unlike other composite decking products which need to be elevated, Primer Mould +Pluspolyethylene plasticMaine Deck wood composite decking can have direct ground contact.Lifecycle Range colours Rainforest Range coloursWood CompositeRecycled product - manufactured uhardwood fibre and recycled premiuLow maintenance - No decoratingonly occasional washingRot free - Will not rot or decayDurable - Hard wearing, does not sCost effective - long lastingFast and easy installationAvailable in a variety of colours -same look and feel as solid hardwooCape Cod Grey Seasoned Mahogany Desert Sand TerracottaCompositionManufactured using recovered hardwoodfibre and recycled premium gradepolyethylene plastic.Available inNominal Length(mm) (m)Lifecycle Range25 x 127 4.88Rainforest Range32 x 137 4.8825 x 127 4.88Available to order13

Anti-Slip <strong>Decking</strong>FinnForest WalkSure TMWalkSureTM low slip decking combines rubber and pressure treated softwooddeck board.The resulting product provides not only an attractive and colourful alternative totraditional timber decking but also a safe, low slip surface in wet or dry conditions, idealfor play areas and pool surrounds. Other applications include public walkways, outdoorsmoking facilities, leisure complexes, hotels, pubs and clubhouses.Available colours:Available to orderAvailable to orderAvailable to orderAvailable to orderAvailable to orderAvailable to orderRed/Charcoal Charcoal/Red Charcoal/Green Sand/Red Sand/Green Sand/Brown Red/BrownNominal Finished Length Code(mm) Dimensions (m)32 x 125 28 x 119 3.6 5643332 x 125 28 x 119 4.2 5643214

Anti-Slip <strong>Decking</strong>John Brash Antislip Plus ® Anti-slip deck boardsJB Antislip Plus® is a slip resistant deck board that provides a beautiful, sustainable andhardwearing solution for decking, steps, ramps, bridges, boardwalks and roof decks,particularly where high levels of footfall are expected.Nominal Finished Length(mm) Dimensions (m)32 x 150 28 x 120 Per m38 x 150 33 x 145 Per mAvailable to order15

Speciality <strong>Decking</strong>FinnForest GrasseDeck TMGrasseDeck® brings a new dimension to decking, creating a softer aesthetic andworking well in contrast to hard landscaping materials.Elegant, sturdy and featuring artificial ‘grass’ on treated softwood boards, GrasseDeck®is easy to maintain and is ideally suited for domestic use within gardens, courtyards,balconies and around spas and swimming pools.Nominal Finished Length Code(mm) Dimensions (m)32 x 150 28 x 144 4.5 5643516

Speciality <strong>Decking</strong>FinnForest Thermowood TMThe inviting dark tones may resemble hardwood, yet ThermoWood® is made fromScandinavian softwood. The heat treatment that creates ThermoWood® uses nochemicals, which gives the added benefit that you know your deck is good for theenvironment and naturally resistant to weather.Nominal Finished Length(mm) Dimensions (m)32 x 125 26 x 118 3.9Other lengths are available, please ask for detailsAvailable to order17

Balustradingstrading FinnForestrails & postssic softwood Balustradingbalustrading can easily beed to match the decking and fencing ofrails & postschoice. Choose from the solid reliabilityAvailable to ordere Roman column balustrade, theant lines Balustrading of the turned rails spindle & or, for aclean, posts modern Classic look, softwood the squarele. Each balustrading one is finished can to easily the highest bedard and stained guarantees to match you years the ofyment decking your garden. and fencing of yourchoice. Choose from the4 For solid sizes & reliability specifications of the Romancolumn balustrade, theelegant lines of the turnedspindle or, for a more clean,modern look, the squarespindle. Each one is finishedto the highest standard andguarantees you years ofenjoyment in your garden.Square spindleTurned spindleRoman column > page 17 for details on constructing deck board end posts> www.finnforest.co.ukFor a list of nearest stockists18

BalustradingFinnForest Tuscanybalustrade kitCode58359An elegant railing combining the naturalbeauty and strength of wood with curvedaluminium balusters to create a modernblend of style and convenience.Pre-drilled for ease of installation,complete with fixings. Posts not included.FinnForest Traditionalbalustrade kitCode58360A wooden hand and base railcomplementing a set of smooth blackaluminium balusters to create a timeless,classic appeal.Pre-drilled for ease of installation,complete with fixings. Posts not included.FinnForest Clearviewbalustrade kitCode58361A glass railing system with high qualitypreservative treated softwood top andbottom rails, a contemporary treatedsoftwood cap rail and seven cleartempered safety glass panels.This kit is pre-drilled for ease ofinstallation. Posts not included.19

20Tips on <strong>Decking</strong>

Tips on <strong>Decking</strong>Don't forget to look for WoodWorks inthe next issue of Professional Builder7. Mix the deck finishesAlternative deck boards,for example GrasseDeck ®or WalkSure TM not onlyadd a striking look to thearea but also play afunctional role in reducingthe amount of debris anddirt transferred fromfootwear onto the deck.Ideal for steps, walkwaysand pool surrounds.8. Fixing deck boardsTo prevent the timbercupping, it’s always best tofix boards down securelywith two fixings not just one.Screws tend to provide amore secure fixing. It’srecommended to drill apilot hole first beforescrewing down,alternatively use a selfcountersinking screwwhich will save time.Allow an expansion gap of around 5mm betweeneach deck board, this will allow for expansion ofthe timber and assist with drainage.Position the fixing at least20mm from the edge ofthe deck board. Whenjoining two cut deckboards together in a run,fix with screws 10mmfrom the end of eachboard, at an angle toensure secure fixing intothe joists below.9. Balustrade kits save timeTo restore an old and tireddeck or add perspective toa new one, use balustradekits that have pre-drilledhand and base rails and allthe necessary fixings.Traditional and Tuscany kitsfrom Finnforest are ideal.The balusters are finishedin a powder coated, durableblack paint and can beinstalled in no time.Tuscany balustrade kitClearview balustrade kitTraditional balustrade kit> www.finnforest.co.uk or call 0800 00 44 44For step by step build guides21

Planning Your DeckA general guide for constructing a deckImportant Information About Your <strong>Decking</strong>Important Information About Your <strong>Decking</strong>1. Always pre-drill pilot holes prior to fixing with screws.1. Always pre-drill pilot holes prior to fixing with screws.2. Use stainless steel screws and fixings to eliminate rust stains.3. Keep 2. Use posts stainless out of steel contact screws with and the fixings ground to eliminate or standing rust stains. water.4. To 3. maintain Keep posts the out colour of contact of your with deck the treat ground it or with standing a pigmented water.stain 4. To or maintain oil. the colour of your deck treat it with a pigmented stain or oil.Without treatment, exposure to UV light will cause the colour to fade.Without treatment, exposure to UV light will cause the colour to fade.Tools RequiredTools Spade requiredSpadeStraight edge or chalk lineSpirit levelStraight edge or chalk lineSuitable fixingsSpirit levelDrill and hammerSuitable fixingsScrewdriverDrill andHand/PowerhammersawScrewdriver Metal post supports (optional)Hand/Power sawMetal post supports (optional)Safety FirstWear gloves to avoidSafetysplinters.FirstWear gloves to avoid splinters.Avoid prolonged inhalation of sawdust from wood.Avoid prolonged inhalation of sawdust from wood.When using power tools wear safety goggles to protect your eyes fromWhen using power tools wear safety goggles to protect your eyes from thethe possibility of flying particles.possibility of flying particles.A general guide for constructinga deck continued> A guide to constructing a deck continued overleaf…step 1 Preparing the siteMark out desired area for deck with wooden pegs and string. Thisstep 1willPreparinghelp youthevisualisesitethe size of the finished deck and act as aMark out desired area for deck with wooden pegs and string. This will help you visualise the sizeguide to preparing the site. All earthed areas should be coveredof the finished deck and act as a guide to preparing the site. All earthed areas should be coveredwith weed control membrane to stop weeds and other growth. Ifwith weed control membrane to stop weeds and other growth. If your ground is flat and level youyour ground is flat and level you can proceed to Step 3. However,can proceed to Step 3. However, if you wish to raise the deck from ground level or the ground isif you wish to raise the deck from ground level or the ground isuneven or sloped, you should proceed to Step 2.uneven or sloped, you should proceed to Step 2.step 2 Raised deckstep 2 If Raised you choose deck to raise your decked area, the raised deck will needIf you choose to be to raise supported your decked with area, posts. the raised In deck most will circumstances need to be supported a with distance posts. Inofmost circumstances 1.8m between a distance posts of 1.8m should between be posts sufficient. should be This sufficient. may This vary may depending varydepending on on the joist size, size, fixings fixings used and used the potential and the loading. potential Posts will loading. be required tosupport Posts central will joists be as well required as the perimeter to support frame. central joists as well as theperimeter frame.If required If required posts can be posts fixed by can either be concreting fixed by the post either directly concreting into the ground the or post using metal directlysupports* into (see the diagram ground opposite). or Using using a level, metal find supports* the desired floor (see height diagram on the posts opposite). andmark this Using accordingly. a level, This find should the provide desired you with floor the position height of the on top the of your posts deck board and mark andtherefore this enable accordingly. you to identify This the joist should position for provide fixing. Secure you the with joists the using position suitable fixings, of thefor example joist hangers, screws or coach screws.top of your deck board and therefore enable you to identify the*This method is recommended if you are using ThermoWoodjoist position for fixing. Secure the joists ® posts.using suitable fixings, forexample joist hangers, screws or coach screws.Additional supportif requiredSide BeamMetalPost SupportSolid FootingPostEndBeamstep 3 FrameworkCut the side joists (A) that will form the sides of the deck to the size you require and mark theposition of the floor joists (B) at 400mm centres.CCut the deck floor joists (C) to length and place the floor joists in position where the deck is22required. Assemble the framework using 3 screws, or alternatively joist hangers, per joist end.Please note: screwing through the side beam into the end of joists is only recommended for

ample joist hangers, screws support coach central screws. joists as well as the perimeter frame.method is recommended if you are using ThermoWood ® posts.If required posts can be fixed by either concreting the post directly into the ground or using metalA general guide for constructing a deck3 Framework step 3 Frameworksupports* (see diagram opposite). Using a level, find the desired floor height on the posts andmark this accordingly. This should provide you with the position of the top of your deck board andtherefore enable you to identify the joist position for fixing. Secure the joists using suitable fixings,for example joist hangers, screws or coach screws.*This method is recommended if you are using ThermoWood ® posts.Cut the side joists (A) that will form the sides of the deck to thee side Chemical joists (A) that free will form the sides of the deck to the size you require and mark the Low slipsize you require and mark the position of the floor joists (B) aton of the The floor wood joists free (B) from at 400mm any chemicals centres. but, due to heatIndependently tested and conforms to having400mm centres.treatment, still has allCut the deck floorstep the properties 3joistsFramework of a preserved timber.a low potential for slip.C(C) to length and place the floor joistse deck floor joists (C) to length Cut the and side place joists (A) the that floor will form joists the in sides position of the deck where to the the size deck you require is and mark thein position wherepositiontheof thedeckfloor joistsis required.(B) at 400mm centres.Assemble the frameworked. Assemble Legal using & the3 sustainableframework using 3 screws, or alternatively joist hangers, per joist end.screws, or alternatively joist hangers, per joist end. Tempered glasse note: The screwingPlease timber throughnote: used in screwing this the Cut product side the deck beam has through floor into been joists the (C) legally to endthe length sourced ofside and joists place beam and is the only floor recommendedinto joists the in position end where forof the deck Has is increased strength and if broken breaks into smallAd level procured decks.joists is from only sustainable required.recommended and Assemble well managed the frameworkfor ground forests. using 3 screws, or alternatively joist hangers, per joistlevel decks.cuboid end. fragments rather than irregular shards making itPlease note: screwing through the side beam into the end of joists is only recommended forBa safe option when A children are present.ground level decks.BLow maintenanceRequires no waterproofing, painting, staining, or similarmaintenancestep 4whenFixingused in manydeckexteriorboardsapplications;only Cut requires your periodic deck boards cleaning. to the required length. Place the first board with4 Fixing deck boardsthe end flush with step 4 the Fixing face deck of boards the front of the deck. Fix this first boardur deck boards to the required Cut your length. deck boards Place to the required first board length. with Place the first end board flush with with the end the flush face with the faceto each joist and always pre-drill a pilot hole prior to fixing. The gapof the front of the deck. Fix this first board to each joist and always pre-drill a pilot hole prior tofront of the deck. Fix this first board to each joist and always pre-drill a pilot hole prior tobetween your boards fixing. The gap should between your be boards 5-8mm should be for 5-8mm for drainage*. Place the next board. The gap between your boards should be 5-8mm for drainage*. Place the next boardPlace the next board parallel to the parallel first and continue to the in the first same and way until continue the last board in is laid. the same wayel to the until first and the continue last board in *Please the same note: thisis laid. way will until vary for the Composite last board due to is the laid. different fixing system.se note: *Please this will vary note: for Composite this will due vary to for the different Composite fixing system. decking due to the differentfixing system.16w much do I need?How much do I need?MetalPost SupportSolid Footing400mmC400mmBeam5mm 5–8mm5mm 5–8mmUSING 150mm width nominal size DECK BOARDSMetres 1 2 3 4 5 6 7 8 9 101 7 14 21 28 35 42 49 56 63 702 14 28 42 56 70 84 98 112 126 1403 21 42 63 84 105 126 147 168 189 2104 28 56 84 112 140 168 196 224 252 2805 35 70 105 140 175 210 245 280 315 3506 42 84 126 168 210 252 294 336 378 4207 49 98 147 196 245 294 343 392 441 4908 56 112 168 224 280 336 392 448 504 5609 63 126 189 252 315 378 441 504 567 63010 70 140 210 280 350 420 490 560 630 700Use for 150mm Softwood, GrasseDeck ® andHardwood deck boardsUSING 125mm width nominal size DECK BOARDSMetres 1 2 3 4 5 6 7 8 9 101 8 16 24 32 40 48 56 64 72 802 16 32 48 64 80 96 112 128 144 1603 24 48 72 96 120 144 168 192 216 2404 32 64 96 128 160 192 224 256 288 3205 40 80 120 160 200 240 280 320 360 4006 48 96 144 192 240 288 336 384 432 4807 56 112 168 224 280 336 392 448 504 5608 64 128 192 256 320 384 448 512 576 6409 72 144 216 288 360 432 504 576 648 72010 80 160 240 320 400 480 560 640 720 800Use for 125mm Softwood, Walksure andThermoWood ® deck boardsUSING 140mm width DECK BOARDSMetres 1 2 3 4 5 6 7 8 9 101 7 14 21 28 35 42 49 56 63 702 14 28 42 56 70 84 98 112 126 1403 21 42 63 84 105 126 147 168 189 2104 28 56 84 112 140 168 196 224 252 2805 35 70 105 140 175 210 245 280 315 3506 42 84 126 168 210 252 294 336 378 4207 49 98 147 196 245 294 343 392 441 4908 56 112 168 224 280 336 392 448 504 5609 63 126 189 252 315 378 441 504 547 63010 70 140 210 280 350 420 490 560 630 700Use for 140mm Composite deck boardsPlease note: the number of boards may varydepending on the design and shape of your deck.Check the amount you need before you buy,as you may need additional boards.The tables above include the gaps requiredbetween the boards.19 23

Installing a Softwood Balustrade SystemA simple guide to installing a balustrade on your decked area.Please note: if you have purchased a balustrade kit, please refer to the separate instructions included in the pack.Square or turned balustrade1. Attach the base rails in between the posts using angle brackets,at a maximum of 99mm height above the deck2. Cut the fillet section into maximum 99mm segments3. Inlay segments of 99mm fillet followed by a spindle-sized gap.Fillets should be secured to the base rail with panel pins4. Repeat this process for the handrail5. Insert all of the spindles into the gaps left between the fillet andcover with the hand rail.You may wish to use wood glue before inserting the spindles6. Fix the handrail to the posts using angle brackets7. The minimum handrail height for a ballustrade ona domestic deck is 900mmRoman columns1. Screw down through deck board to roman column2. Screw up through deck board to joist above; this ensuresno screws are visible at the topPostbalustradeInstalling asystemsoftwoodbalustrade systemFilletAngleBracketsPostPostthen screw upthrough deckboard to joistabove, thisensures noscrews arevisible at the top99mmmax.AngleBracketsthen screw upthrough deckboard to joistabove, then screw this upensures through nodeckscrews board are to joistvisible above, at this the topensures noscrews arevisible at the topAngleBrackets99mmmax.99mmmax.99mmmax.99mmmax.Base RailHand RailA simPleaseA simseparPleassepaSquar1. AttacSquaHand Railat a m1. Atta2. Cut that aFillet3. InlaySegmentfirst screw down through deck2. CutFilletsboard to roman columnFillet3. InlaSegment4. RepeFille5. Inser4. RepYou mBase Rail5. Inse6. Fix thYouBase RailWIDTH 6. Fix t90mmfirst screw down through deckboard to roman columnfirst screw down through deckboard to roman columnHEIGHT 458mmHEIGHT 458mmWIDTH90mmSegmentHEIGHT 458mmWIDTH90mmRoma1. ScrewRom2. Screw1. Screthis e2. ScrethisRoman column deck board end post - assembly1. It is important to treat any exposed timber with a suitable endgrain preserver to help protect against rot and decay2. Cut four lengths of deck board to the desired height to matchyour roman column wall3. Secure these together as shown (left) to create a complete postRoman column post cap - assembly• Cut two triangles from the end of a deck board; these will formthe top of the post45º275/280mmapprox45º 45º275/280mmapprox90º90º approx45º 45º45º 90º 45º 45º90º45º90º45º45º90ºRoma1. It is imIf you choose Rom totohidhelfixings, attachIf you choose to hide the 1. the It is p2. Cut fofixings, attach the post roman to columnthe roman columnto hhandrail before your full rhandrail If you choose before to fully hide theenclosing the post 2. Cutfixings, attach enclosing the post to the 3. post Secuthe roman columnyourhandrail before fullyenclosing the post 3. Sec45ºRoma• Rom Cut twthese• Cutthes24

Additional PartsDEKThe Complete <strong>Decking</strong> SystemUniclassL81215:P511Cl/SfB(90.41) Hi3CoverDek SoftwoodTreated HandrailNominal Length Code(mm) (m)Ex 50 x 75 1.8 619Ex 50 x 75 2.4 620CoverDek SoftwoodTreated SpindleNominal Length Code(mm) (mm)50 x 50 900 618EPIC(39 x 39 Fin.)Q13:X52CoverDek SoftwoodTreated Base RailNominal Length Code(mm) (m)Ex 25 x 75 1.8 621Ex 25 x 75 2.4 622CoverDek SoftwoodTreated Newell PostNominal Length Code(mm) (m)94 x 94 Fin. 1.2 62394 x 94 Fin. 1.8 624CoverDek Joists(Ground contact)Tanalised to H/C 4Nominal Length Code(mm) (m)47 x 150 3.6 6055847 x 150 4.8 60559Golden Oak Bullnosestep edgeWith an integral half round nosingmoulded on the step edge, ourbullnose step edge provides a stylishclean finish for step situations and isavailable in four colours.Nominal Length Code(mm) (mm)33 x 50 3600 61458Durafix Trimhead FixingsThat’s how easy the ‘hidden’ fixing is. Justscrew straight in, no pre-drilling, countersinking or fiddly clip fixings. The uniqueLastane material closes back over theMillboard Trimhead fixing, leaving a virtuallyindishtinguishable hole or at the most a verysmall entrance hole.All our reccommended board fixings haveself-cutting tip and a torx drive head forease of use. Ensure the head is 5mm belowthe surface.Nominal Code(mm)4.5 x 70 61459500 per packABMillboard Domestic Joist Shoe• Ideal for flat roofs, concrete, paving or tarmac• Does not pierce roof membrane• Height adjusting levellers in 3mm increments• Creates moisture barrier between joists androof surface• Very quick and easy to install• Available in 38mm• Can take up to 250kg weight loading each.AMillboard Plas-Pro recycled Bplastic subframe system• Up to 100% recycled plastic• Reduces landfill• Non rot, split or crack• Ideal for Jetty’s, boardwalks, fishing platforms,dipping platforms, roof terraces, leisure...• Does not leach chemicals or tannins• Range of profiles and coloursspring 2011Nominal (mm) Code38mm 61908Takes joists up to 46mm wideNominal (mm)120 x 40 x 2000, 120 x 60 x 3000& 100 x 100 x 3000 Available to order25

<strong>Decking</strong> Stains and ProtectionRonseal <strong>Decking</strong> Stain is hardwearing, scuff resistant formula, resists cracking, peeling& blistering. Quick Drying - rainproof in 90 minutes, out peforms conventional woodstainson decking. Ronseal <strong>Decking</strong> Seal provides a clear protective barrier that repels moistureand helps protect the timber from water damage, while allowing the wood to breathe.It’s clear finish allows decking to weather naturally over time.Ronseal <strong>Decking</strong> Restorer is the quick and easy way to safely restore grey or weathereddecking back to its natural appearance with the minimum of effort and fuss. The uniquenon-acidic gel formulation will brighten and revive dull and weathered timbers to leaveyour deck looking clean, newly restored and transformed to it’s original colour.Ronseal <strong>Decking</strong> Protector resists greying, surface mould and algae growth. It is aunique wax enriched formula that creates a superb barrier against water penetrationand helps prevent discoloration by protecting the deck against constant wetting, drying,splitting and swelling. Ideal for spraying. Provides the ultimate waterproofing protection,Unique wax enriched formula creates a superb water resistant barrier.Ronseal <strong>Decking</strong> Oil is a durable scuff resistant tinted oil that forms a waterproofbarrier to protect against weathering, warping, swelling, drying and splitting. It resistsmould and algae growth and its fade resistant finish protects against UV rays.For use on hardwood and softwood decking.Ronseal Cleaner & Reviver cleans and revives timber decking, removing dirt, grease,fungus, stains, algae and mildew. It opens the pores of the wood allowing maximumadhesion of coatings for a lasting finish.Ideal for use prior to applying a decking finish.Ensele Brush-On End Grain Preservative is a water based preservative based oncopper/triazole technology. Whenever Tanalised timber is cross-cut, notched or bored onsite, the exposed surfaces must be re-treated with Ensele end-grain preservative tomaintain the integrity of the protective system.Weedex 70 is suitable for tough perennial weeds, flower and shrub beds, vegetable beds,aggregate areas (paths etc) under decking, containers and baskets.Finished CodeDimensions (m)1 x 14 321852 x 25 321862 x 50 3218726

<strong>Decking</strong> FixingsFastenMaster GuardDog Exterior Wood ScrewGuardDog is a versatile exterior wood screw used for a variety ofapplications. The PoziSquare Drive eliminates the strip out of a fastener.Fully tested, fully guaranteed in ACQ, Cedar, Redwood and Copper Azole.The design features of this product include:• Versatile head style can be used with the PoziSquare Drive, #2 square drive, and Phillips drive• Guaranteed corrosion resistance• Colour matched to blend in with the new pressure treated decking• Sharp threads quickly penetrate lumber• Free PoziSquare driver bit included• Available in 40mm, 50mm, 63mm & 90mmFischer <strong>Decking</strong> ScrewsThe design features of this product include:· Unique thread design provides exceptional holding power.· No pre-drilling as these screws can drive into the hardest wood.· Spiral flutes are suitable for end grain applications· Weather resistant coating make them ideally used for all exterior timber applications.· Packed in a handy clear plastic carry box, which can be filled and re-used again.Spax® Wirox ScrewsAn excellent quality construction screw with universal applications. TheWirox coating provides a high level of surface hardness to give greaterresistance to coating damage, and possesses anti-corrosion resistance 10times greater than yellow zinc.The design features of this product include:• Environmentally friendly: chrome vi-free• No pre-drilling required• No splitting even when close to edgePaslode Quattro Woodscrews Zinc PlatedSpecifically developed to ensure installation is simple and hassle free.With no pilot holes required and no damage caused to wood, MDF andchipboard surfaces.The design features of this product include:• Zinc plated Internal Wood Screws• Quattro thread shank - for excellent cut into timber fibres• Profpoint cutting tip - minimises the risk of splitting• Countersunk ribbed head - beautiful finish with no surface damage• TX Drive recess - high torque for powerful driving (Free bit in every box)27

Products & ServicesWhy not visit your local <strong>Covers</strong> Depot. With over 23,000 products stocked at ourbranches you will find everything you need, whether you are doing DIY, Decorating,or Building a House or Commercial Property from scratch!28Products TimberBlockboardBolted & Connected TrussesBulk Timber upto 12m longCarcassing up to 7.8m lengthsCedar Shingles, Cedar Shiplap, CedarTGVChipboard<strong>Decking</strong> - Softwood & HardwoodDoors - Interior & Exterior fire doorsDry Stress Graded TimberFencing MaterialsFlag PolesFloor CassettesProducts BuildingAdhesives & SealantsAggregatesBathrooms & AccessoriesBiomassBrasswareBricks & BlocksBuilders FixingsCalor GasCementCirculating PumpsCladdingsConcrete MixersConcrete ProductsCopper CylindersCopper TubeCurtain TracksDamproofing ProductsDe-humidifiers<strong>Decking</strong> Nails, Screws & AccessoriesDecorators ProductsDoor FurnitureDrainageServicesBrick MatchingContract Kitchens and BathroomsDeliveryEco ExpertiseKitchen and Bathroom Design ServiceLandscaping Design ServiceMilling ServiceFrames & Linings (All sizes)Glulam BeamsHardboardHardwoodsInsulation BoardsJoinery SoftwoodsMarine Grade Plywood Two GradesMDF Sheets & MouldingsPlasterboardsPlaster Laths 4mm x 25mmPlywoodsPrepared & Moulded TimberPrimed Prepared Timber FacilitiesElectrical FittingsFelts & Damp CourseFencingGarage DoorsGarden SuppliesGround Source Heat PumpsHeating ControlsHousewaresImmersion HeatersInsulation ProductsIronmongeryJoist Hangers & StrapsKitchens & AccessoriesLadders & StepsLeadLintelsManhole <strong>Covers</strong> & FramesMelamine BoardNails, Screws & BoltsPaints, Varnishes & PreservativesPaving SlabsPolycarbonate RoofingPaint MixingPriming and ServiceSawn and Prepared TimbersSawmilling & Machining FacilitiesSheet CuttingSpecial Order ServiceSpecialist ProductsProtim Preservative TreatmentsRoof PackagesRoof TrussesScaffold BoardsSheet MaterialsSleepersStairsTimber Frame StructuresTrussed RaftersTruss Joist ‘I’ BeamsVeneered PlywoodsWindows ~ Wood and UPVCand much more...PlasterboardsPlumbing AccessoriesProtective ClothingRadiatorsRainwater HarvestingRainwater & Soil SystemsRamin MouldingsRoof Slates & TilesSanitarywareShelving SystemsShowersSolar PanelsSun tubes/tunnelsTanks & LaggingsThermafleeceTools - Hand & PowerUnderfloor heatingWaste & OverflowWoodcare Productsand much more...Special Machining serviceStrength GradingTanalith Preservative TreatmentsTimber MouldingTimber Treatmentsand much more...

Other ProductsTimberOur reputation as the South of England’s Timber Specialistshas been built on providing our customers with an unrivalledrange of quality timber, knowledgeable staff and a reliabledelivery service. We import timber direct from well managedand sustainable forests and offer FSC® and PEFC certifiedgoods wherever possible.Our investment in special milling technology allows us to makethe claim…… “If you can draw it, we can produce it”. We canprovide priming, sheet cutting; stress grading and timbertreatment systems to ensure our timber will meet yourspecification. We can also treat timber for both internaland external applications.Softwood RangeKiln dried and graded carcassing • Preservative treatment • CLS studding • Treated battens • Scaffold boardsCedar shingles Shiplap and TGV • PAR and mouldings • Top grade sawn Redwood • <strong>Decking</strong> • FlooringHardwood RangeEuropean Oak • Tulipwood • Iroko and Utile • Sapele and Meranti • American White Oak & AshAmerican Cherry • White Beech • Steamed Beech • Idigbo • American Black WalnutHeavy Building MaterialsBuilding on our experience as a leading independentsupplier of heavy and related building materials, we havea great understanding of both trade and retail needs.Our knowledgeable staff can source almost any item foryou and give advice on the most suitable products to use.We offer a consistently reliable delivery service from stockand provide a direct sales service. Our quotationdepartments provide a fast response for enquiries fordirect to site loads and ex-depot trade. Aggregates areavailable either loose, bagged or in non-returnable bulk bags.Our major Depots hold a wide range of bricks relevantto local requirements. All depots hold stocks of cement,plasters, plasterboard, insulation and drainage and at Chichester specialist stocks are held of new and secondhand clay and cement roof tiles.Delivery vehicles are equipped with mechanical handling equipment to ensure fast and efficient off loading atyour site.Hardware & DecoratingOur vast range of lightside products is forever growing!We are constantly seeking new products, ranges and areaswhich we see as beneficial to our customers.Our skilled sales office staff are equipped with productlibraries to assist the sourcing of special and unusual orders.All of our depots are staffed by experienced individuals whoall have specialist knowledge of the products we sell.29

Other ProductsLandscaping<strong>Covers</strong> stock an extensive range of exciting landscaping materials from theleading manufacturers. Our inspirational selection of natural stone,concrete paving, block paving, decorative aggregates, decking, fencingand garden buildings will ensure you find the perfect products to helpyou transform your garden or driveway. <strong>Covers</strong> landscape centres all boasta diverse range of products on display to assist you with your selectionand knowledgeable staff who can calculate the quantities you require foryour project.FlooringNothing beats the feel of good flooring under foot, whether it’s solid,engineered or laminate. Practical, hard wearing and requiring minimalmaintenance, the best solid flooring has remarkable resilience to theknocks and bumps of everyday life – and can last for decades. At <strong>Covers</strong>,we’re able to offer over 20 different types of timber and timber-style floorcoverings from major manufacturers and importers, with knowledge andinstallation advice to match.Kitchens and BathroomsOur dedicated kitchen and bathroom showrooms at Chichester andBognor Regis offer an array of traditional and contemporary designs toaccommodate all tastes and budgets. <strong>Covers</strong> experienced staff will helpyou through the decision making process and will provide you with a freedesign and quotation.Trade Kitchens and BathroomsAt <strong>Covers</strong>, we never forget that kitchens and bathrooms sell houses.That’s why we offer a vast selection of kitchens, bathrooms, appliancesand accessories to reflect all the very latest design trends. With rangesfrom leading suppliers such as Sheraton, Symphony and Ideal Standard,we have everything you need. We will seamlessly guide you throughthe process of selecting a new kitchen or bathroom for your latestdevelopment, conversion or extension. Consultation, design, quotation,delivery. We’ve got it all under one roof – with a patient and responsiveattitude to service.Doors, Windows and ConservatoriesWe’re the areas largest stockist of quality doors and windows withdedicated showrooms in Chichester, Bognor Regis and Lewes. We stockhigh technology doors and windows from world class suppliers likePremdor, Jeld-Wen, Vicaima, Johnson Aldridge and many more. <strong>Covers</strong>are a proud member of the British Woodworking Federation, which isresponsible for the quality control and development of doors and windowsin the UK.<strong>Covers</strong> also supply an excellent range of made to measure UPVC products,such as doors, windows and conservatories. Fibreglass doorsets are alsoavailable in various colours and styles.Eco Centre<strong>Covers</strong> has put green issues to the top of our agenda and opened theSouth East’s first ever Eco Centre.Customers can now view the very latest eco building products and appliancesunder one roof. The Eco Centre is a vital resource for consumers tolearn about how to make their home energy efficient and eco friendly.• Working solar panel display • Sheepswool Insulation• Wood Pellet Boilers • Heat Pumps• Heat Recovery Systems • Water Saving Devices• Under Floor Heating • Photovoltaic Solar systems30

SHEET MATERIALS 2008.pmd16/25/2008, 8:32 AMOther <strong>Brochure</strong>swww.covers.bizwww.covers.bizwww.covers.bizwww.covers.bizPRODUCTS & SERVICES BROCHURE - 2010.qxp 05/07/2010 16:35 Page 1Sustaining the futureA Customer’s Guide toThe Code forSustainable HomesAre you ready?A step-change in sustainablehome building practiceTimber & Builders Merchantswww.covers.bizPick up a brochure at any depot or download fromwww.covers.biz31

Timber & Builders MerchantsTRADE CARDTimber & Builders MerchantsCASH TRADE CARDAPPLICATION FORMTrade discounts on over 30,000products when you apply todayTimber & Builders MerchantsTRADE CARDTIMBER • HEAVY BUILDING MATERIALSLANDSCAPING • FLOORING • IRONMONGERYDOORS & WINDOWS • ECO RANGEHARDWARE & DECORATINGKITCHEN & BATHROOMSwww.covers.bizHow would you like to pay?Cash or AccountTrade Card: If you prefer to pay as you go. You will get trade terms, whichmeans you don’t have to negotiate every time you pay.Credit Account: We offer a 30 day account to qualifying customers on tradeterms, so that you can buy everything at the right price, with account facilitiesof invoices and statements to your office and planned payments dates.** Credit references required. Terms and conditions apply.Depot Account: This offers the benefits of a Credit Account in terms ofinvoices and statements but no credit is offered. Ideal for a small trader whomay send one of their team to collect goods and does not wish to give themcash or to lose the invoices.You can download the application forms for the above from our website www.covers.biz.AldershotBlackwater ParkHampshireGU12 4PQTel: 01252 320554Fax: 01252 341279sales.aldershot@covers.bizMon - Fri : 7.30am - 5.00pmSat : 8.00am - 1.00pmChichesterQuarry LaneWest SussexPO19 8PETel: 01243 785141Fax: 01243 533977enquiries@covers.biz(For opening times, contactindividual department)RudgwickCrinda Landscape SuppliesBrookside Rural ParkSurrey RH12 3AUTel: 01403 824111Fax: 01403 823405sales.rudgwick@covers.bizMon - Fri : 7.30am - 5.00pmSat : 8.30am - 12.00pmTunbridge WellsLongfield Road, North Farm Ind. Est.Tunbridge WellsKent TN2 3EYTel: 01892 533326Fax: 01892 520132sales.tunbridgewells@covers.bizMon - Fri : 7.30am - 5.00pmSat : 8.00am - 12.00pmAlresford3 Prospect RoadHampshireSO24 9QFTel: 01962 738666Fax: 01962 738777sales.alresford@covers.bizMon - Fri : 7.30am - 5.00pmSat : 8.00am - 12.00pmGosportGunners WayHampshirePO12 4DWTel: 023 9260 4400Fax: 023 9260 4410sales.gosport@covers.bizMon - Fri : 7.30am - 5.00pmSat : 7.30am - 1.00pmSouthamptonBelgrave Road, PortswoodHampshireSO17 3ANTel: 02380 556996Fax: 02380 679065sales.southampton@covers.bizMon - Fri : 7.30am - 5.00pmSat : 8.00am - 12.00pmHead OfficeSussex HouseQuarry Lane,ChichesterWest Sussex PO19 8PETel: 01243 785141Fax: 01243 531151enquiries@covers.bizBognor RegisStation YardWest SussexPO21 1BTTel: 01243 863100Fax: 01243 841215sales.bognor@covers.bizMon - Sat : 7.30am - 5.00pmHorshamFoundry LaneWest SussexRH13 5PXTel: 01403 253123Fax: 01403 240101sales.horsham@covers.bizMon - Fri : 7.30am - 5.00pmSat : 8.00am - 12pmBrightonHome Farm RoadEast SussexBN1 9HUTel: 01273 607044Fax: 01273 685208sales.brighton@covers.bizMon - Fri : 7.30am - 5.00pmSat : 8.00am - 12pmLewesCooksbridgeEast SussexBN8 4TJTel: 01273 476133Fax: 01273 400164sales.lewes@covers.bizMon - Fri : 7.30am - 5.00pmSat : 8.00am - 12.00pmBurgess HillPortsmouth114 Fairfield RoadNorway RoadWest SussexHampshireRH15 8NPPO3 5FTActual product/colour may differ from illustration.Tel: 01444 233358Tel: 023 9267 1900items currently available ex-stock Chichester, items not held at local branch are available within approx. 48 hours.Fax: 01444 248099sales.burgesshill@covers.bizMon - Fri : 7.30am - 5.00pmSat : 8.00am - 12.00pmFax: 023 9267 0350sales.portsmouth@covers.bizMon - Fri : 7.30am - 5.00pmSat : 7.30am - 1.00pmTimber & Builders Merchantswww.covers.bizPrinted June 2011Actual product/colour may differ from illustration.All items currently available ex-stock Chichester, items not held at local branch are available within approx. 48 hours.