Effects of Low-Purge Vehicle Applications and ... - MeadWestvaco

Effects of Low-Purge Vehicle Applications and ... - MeadWestvaco

Effects of Low-Purge Vehicle Applications and ... - MeadWestvaco

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

portion <strong>of</strong> the canister carbon bed closest to the<br />

atmosphere port.<br />

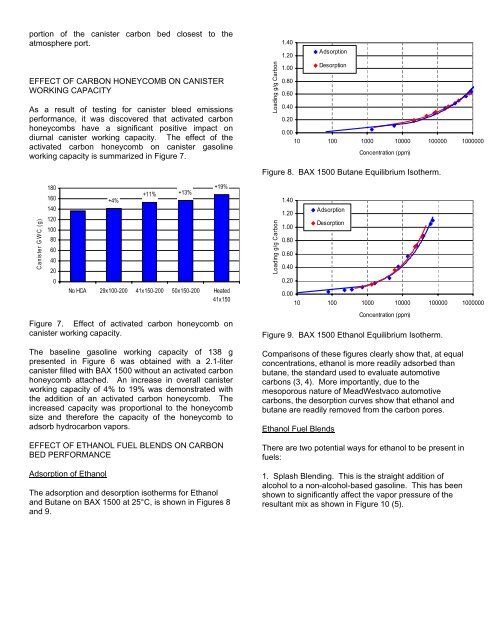

EFFECT OF CARBON HONEYCOMB ON CANISTER<br />

WORKING CAPACITY<br />

As a result <strong>of</strong> testing for canister bleed emissions<br />

performance, it was discovered that activated carbon<br />

honeycombs have a significant positive impact on<br />

diurnal canister working capacity. The effect <strong>of</strong> the<br />

activated carbon honeycomb on canister gasoline<br />

working capacity is summarized in Figure 7.<br />

Canister G W C (g) .<br />

180<br />

160<br />

140<br />

120<br />

100<br />

80<br />

60<br />

40<br />

20<br />

0<br />

+4%<br />

+11%<br />

+13%<br />

+19%<br />

No HCA 29x100-200 41x150-200 50x150-200 Heated<br />

41x150<br />

Figure 7. Effect <strong>of</strong> activated carbon honeycomb on<br />

canister working capacity.<br />

The baseline gasoline working capacity <strong>of</strong> 138 g<br />

presented in Figure 6 was obtained with a 2.1-liter<br />

canister filled with BAX 1500 without an activated carbon<br />

honeycomb attached. An increase in overall canister<br />

working capacity <strong>of</strong> 4% to 19% was demonstrated with<br />

the addition <strong>of</strong> an activated carbon honeycomb. The<br />

increased capacity was proportional to the honeycomb<br />

size <strong>and</strong> therefore the capacity <strong>of</strong> the honeycomb to<br />

adsorb hydrocarbon vapors.<br />

EFFECT OF ETHANOL FUEL BLENDS ON CARBON<br />

BED PERFORMANCE<br />

Adsorption <strong>of</strong> Ethanol<br />

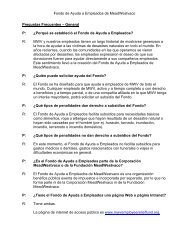

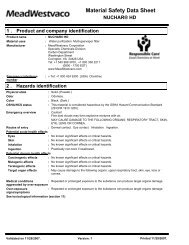

The adsorption <strong>and</strong> desorption isotherms for Ethanol<br />

<strong>and</strong> Butane on BAX 1500 at 25°C, is shown in Figures 8<br />

<strong>and</strong> 9.<br />

Loading g/g Carbon<br />

1.40<br />

1.20<br />

1.00<br />

0.80<br />

0.60<br />

0.40<br />

0.20<br />

Adsorption<br />

Desorption<br />

0.00<br />

10 100 1000 10000 100000 1000000<br />

Concentration (ppm)<br />

Figure 8. BAX 1500 Butane Equilibrium Isotherm.<br />

Loading g/g Carbon<br />

1.40<br />

1.20<br />

1.00<br />

0.80<br />

0.60<br />

0.40<br />

0.20<br />

Adsorption<br />

Desorption<br />

0.00<br />

10 100 1000 10000 100000 1000000<br />

Concentration (ppm)<br />

Figure 9. BAX 1500 Ethanol Equilibrium Isotherm.<br />

Comparisons <strong>of</strong> these figures clearly show that, at equal<br />

concentrations, ethanol is more readily adsorbed than<br />

butane, the st<strong>and</strong>ard used to evaluate automotive<br />

carbons (3, 4). More importantly, due to the<br />

mesoporous nature <strong>of</strong> <strong>MeadWestvaco</strong> automotive<br />

carbons, the desorption curves show that ethanol <strong>and</strong><br />

butane are readily removed from the carbon pores.<br />

Ethanol Fuel Blends<br />

There are two potential ways for ethanol to be present in<br />

fuels:<br />

1. Splash Blending. This is the straight addition <strong>of</strong><br />

alcohol to a non-alcohol-based gasoline. This has been<br />

shown to significantly affect the vapor pressure <strong>of</strong> the<br />

resultant mix as shown in Figure 10 (5).