Inverting Filter Centrifuge - SEFAR

Inverting Filter Centrifuge - SEFAR

Inverting Filter Centrifuge - SEFAR

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

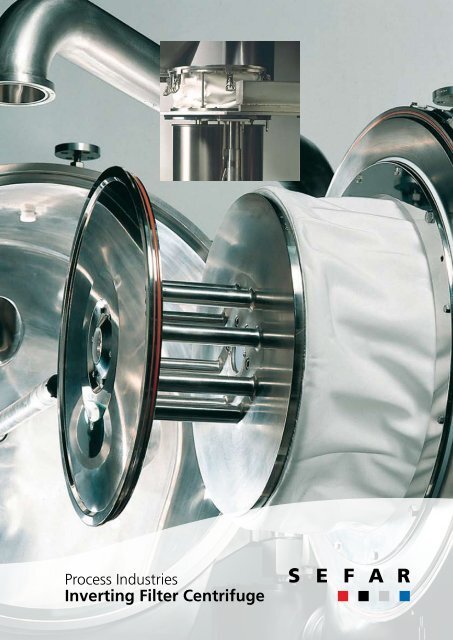

Process Industries<br />

<strong>Inverting</strong> <strong>Filter</strong> <strong>Centrifuge</strong>

Sefar filter cloths for Heinkel<br />

inverting filter centrifuges<br />

Heinkel and Sefar are the two<br />

leading-edge specialists in solid/<br />

liquid separation for the life science<br />

industries – a position gained<br />

through the development of innovative<br />

technologies and compliance<br />

with the most stringent quality and<br />

safety requirements.<br />

1<br />

3 4<br />

3<br />

Zentrifuge<br />

1 filling<br />

3 washing<br />

A new generation of filter cloths<br />

Our new generation of filter cloths<br />

for inverting filter centrifuges optimizes<br />

the filtration performance<br />

(throughput and particle retention),<br />

makes installation/fitting<br />

and cake release easier and has a<br />

longer lifetime together with consistent<br />

quality and traceability.<br />

Sefar is the only filter media<br />

manufacturer in the world that<br />

integrates all the crucial steps<br />

from weaving to fabrication of<br />

the final filter cloth for inverting<br />

filter centrifuges. In this way we<br />

can ensure the quality and traceability<br />

required for applications in<br />

the pharmaceutical industry. The<br />

cooperation between Heinkel and<br />

Sefar now allows users to trace<br />

Our separation equipment and<br />

filter media are in worldwide use<br />

in factories of almost all the wellknown<br />

pharmaceutical enterprises.<br />

Today the names of Heinkel and<br />

Sefar are synonymous with excellence<br />

in separation.<br />

2 2<br />

2 spinning<br />

4 discharging<br />

back the quality of the filter cloth<br />

used in their current operation<br />

back to the original yarn used in<br />

its manufacture.<br />

Advantages<br />

This cooperation provides unique<br />

advantages for users of the new<br />

filter cloth generation:<br />

– direct access to the specific<br />

filtration process know-how of<br />

the original machine manufacturer<br />

Heinkel and the filter<br />

media manufacturer Sefar<br />

– support from the Sefar experts<br />

for filter fabric and filter materials<br />

and the Heinkel experts<br />

for process optimization of<br />

inverting filter centrifuges<br />

– access to a new generation of<br />

filter cloths which are speci-<br />

1<br />

1 <strong>SEFAR</strong> TETEX ® MONO<br />

2 <strong>SEFAR</strong> TETEX ® DLW<br />

3 <strong>SEFAR</strong> TETEX ® MULTI<br />

fically designed for inverting<br />

filter centrifuges<br />

– access to specific solutions<br />

for pharmaceutical filtrations<br />

where Sefar and Heinkel will<br />

provide filter cloths manufactured<br />

under strict quality monitoring<br />

procedures. Sefar will<br />

ensure that all raw materials<br />

used for the <strong>SEFAR</strong> ® PHARMA<br />

Grade Fabrication are either<br />

FDA compliant or have been<br />

thoroughly evaluated during<br />

extraction tests.<br />

– global availability and shortest<br />

possible delivery times through<br />

an optimized distribution network<br />

supported by Sefar and<br />

Heinkel branch offices worldwide.<br />

Individual supply agreements<br />

are available.

<strong>SEFAR</strong> ® PHARMA fabrication<br />

Sefar has established a specially<br />

designed fabrication process to<br />

meet the most critical needs of<br />

the pharmaceutical industry. Sefar<br />

fabrication sites producing<br />

<strong>SEFAR</strong> ® PHARMA-Grade pro ducts<br />

must implement defined GMP-<br />

Guidelines in addition to the tight<br />

quality control systems already in<br />

place.<br />

The guidelines contain directives<br />

for:<br />

– clean liness and traceablility of<br />

all material, components and<br />

supply items/accessories used<br />

for fabrication<br />

– manufacturing documentation<br />

and work instructions<br />

– quality control and final inspection<br />

– employee training<br />

– compliance and implementation<br />

of these guidelines at the<br />

A<br />

B<br />

C D<br />

fabrication plants<br />

– packaging and labelling<br />

Detailed work instructions specific<br />

to <strong>SEFAR</strong> ® PHARMA-Grade products<br />

ensure that the stringent<br />

requirements of cleanliness, traceability,<br />

overall quality and performance<br />

are being met.<br />

However the most important<br />

change to classical fabrication is<br />

the strict limitation of the selection<br />

of usable fabrics and component<br />

items/accessories.<br />

– Only specifically designated<br />

non-filtering component and<br />

supply item/accessories needed<br />

for manufacturing the product<br />

are considered as suitable for<br />

our Pharma products.<br />

– All supply items/accessories<br />

with pro duct contact are either<br />

FDA compliant or have been<br />

A co-operation for your success<br />

Heinkel and Sefar entered into a<br />

close cooperation by combining<br />

their know-how as original machine<br />

and filter<br />

media manufacturers to develop<br />

a new generation of filter cloths<br />

specifically serving the needs of<br />

inverting filter centrifuges.<br />

Installation of a filter cloth<br />

thoroughly evaluated during<br />

extraction tests to ensure<br />

extractable levels do not exceed<br />

the tolerable limits.<br />

Sefar filter cloths for Heinkel<br />

inverting filter centrifuges<br />

Sefar filter cloths are available<br />

for all Heinkel inverting filter<br />

centrifuges. We offer the cloths<br />

in a wide range of materials<br />

such as polypropylene, polyester,<br />

nylon and PTFE to meet the critical<br />

application requirements of<br />

chemical compatibility and heat<br />

resistance. Our precision-woven<br />

fabrics are designed in a wide<br />

variety of weave styles using the<br />

advantages of mono-filament and/<br />

or multifilament fibers. After final<br />

surface treatments our fabrics are<br />

ready to meet the most stringent<br />

requirements of our demanding<br />

customers.<br />

A Drum diameter<br />

B Cloth length<br />

C Process section<br />

D Engine section

Let us quote your Heinkel inverting filter centrifuge cloths<br />

To quote for your filter cloth we need the following information:<br />

– Heinkel article number if available<br />

– <strong>Centrifuge</strong> size or machine number (e.g. HF 800./ or 1245/13)<br />

– Fabric product reference (e.g. 05-4-660 K PHARMA)<br />

– Cloth length (of your cloth)<br />

– Special design features (e.g. wear strips)<br />

Want to improve your process? Let us know what you would like to improve.<br />

You can be sure of an optimal solution based on the joint know-how of Sefar<br />

experts for fabric and filter materials and Heinkel experts for process optimization<br />

of inverting filter centrifuges.<br />

Please contact your nearest Sefar or Heinkel dealer!<br />

Standard cloth sizes<br />

Machine type Drum diameter (mm) Cloth length (mm)<br />

HF 300.1 300 185<br />

HF 450.1 450 320<br />

HF 600.1 600 320<br />

HF 800.1 800 435<br />

HF 1000.1 1000 480<br />

Sefar Headquarter<br />

Sefar AG<br />

Filtration Solutions<br />

P.O.Box<br />

CH-9410 Heiden<br />

Switzerland<br />

Phone +41 71 898 57 00<br />

Fax +41 71 898 57 21<br />

E-mail filtration@sefar.com<br />

Sefar Filtration Inc.<br />

Buffalo<br />

111 Calumet Street<br />

Depew, New York 14043<br />

USA<br />

Toll Free +1 877 481 3626<br />

Phone +1 716 683 4050<br />

Fax +1 716 683 4053<br />

E-mail filtration@sefar.us<br />

Sefar Singapore Pte Ltd.<br />

371 Beach Road<br />

KeyPoint, #21-01/02/03<br />

Singapore 199597<br />

Phone +65 6 299 90 92<br />

Fax +65 6 299 63 59<br />

E-mail info.sg@sefar.com<br />

www.sefar.com 3105-0121/500 / 12.2008