Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

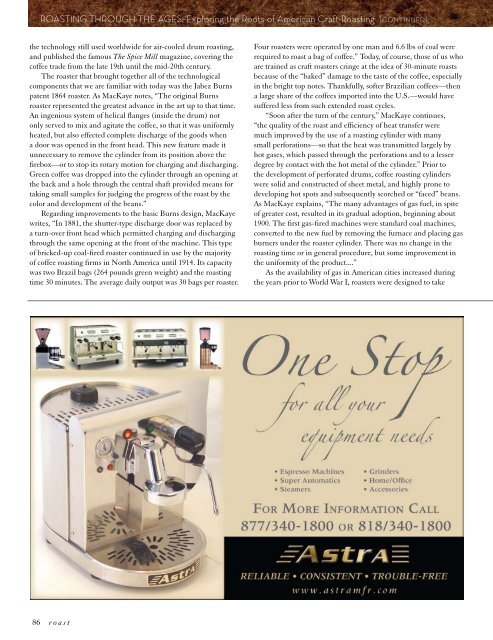

ROASTING THROUGH THE AGES: Exploring the Roots of American Craft <strong>Roasting</strong> (continued)the technology still used worldwide for air-cooled drum roasting,and published the famous The Spice Mill magazine, covering thecoffee trade from the late 19th until the mid-20th century.The roaster that brought together all of the technologicalcomponents that we are familiar with today was the Jabez Burnspatent 1864 roaster. As MacKaye notes, “The original Burnsroaster represented the greatest advance in the art up to that time.An ingenious system of helical flanges (inside the drum) notonly served to mix and agitate the coffee, so that it was uniformlyheated, but also effected complete discharge of the goods whena door was opened in the front head. This new feature made itunnecessary to remove the cylinder from its position above thefirebox—or to stop its rotary motion for charging and discharging.Green coffee was dropped into the cylinder through an opening atthe back and a hole through the central shaft provided means fortaking small samples for judging the progress of the roast by thecolor and development of the beans.”Regarding improvements to the basic Burns design, MacKayewrites, “In 1881, the shutter-type discharge door was replaced bya turn-over front head which permitted charging and dischargingthrough the same opening at the front of the machine. This typeof bricked-up coal-fired roaster continued in use by the majorityof coffee roasting firms in North America until 1914. Its capacitywas two Brazil bags (264 pounds green weight) and the roastingtime 30 minutes. The average daily output was 30 bags per roaster.Four roasters were operated by one man and 6.6 lbs of coal wererequired to roast a bag of coffee.” Today, of course, those of us whoare trained as craft roasters cringe at the idea of 30-minute roastsbecause of the “baked” damage to the taste of the coffee, especiallyin the bright top notes. Thankfully, softer Brazilian coffees—thena large share of the coffees imported into the U.S.—would havesuffered less from such extended roast cycles.“Soon after the turn of the century,” MacKaye continues,“the quality of the roast and efficiency of heat transfer weremuch improved by the use of a roasting cylinder with manysmall perforations—so that the heat was transmitted largely byhot gases, which passed through the perforations and to a lesserdegree by contact with the hot metal of the cylinder.” Prior tothe development of perforated drums, coffee roasting cylinderswere solid and constructed of sheet metal, and highly prone todeveloping hot spots and subsequently scorched or “faced” beans.As MacKaye explains, “The many advantages of gas fuel, in spiteof greater cost, resulted in its gradual adoption, beginning about1900. The first gas-fired machines were standard coal machines,converted to the new fuel by removing the furnace and placing gasburners under the roaster cylinder. There was no change in theroasting time or in general procedure, but some improvement inthe uniformity of the product....”As the availability of gas in American cities increased duringthe years prior to World War I, roasters were designed to take86roast