Download PDF - NSC Cylinders

Download PDF - NSC Cylinders

Download PDF - NSC Cylinders

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

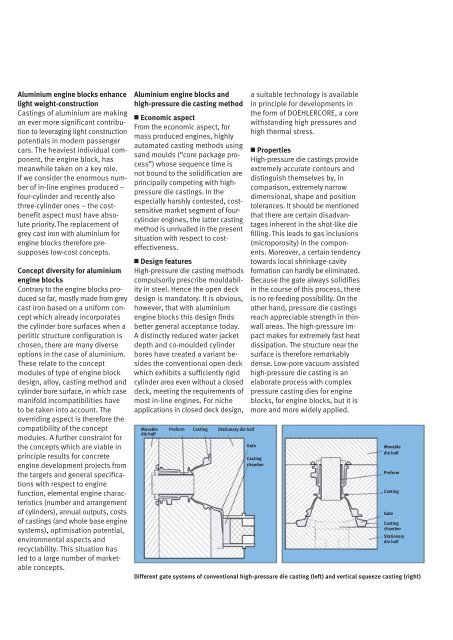

Aluminium engine blocks enhancelight weight-constructionCastings of aluminium are makingan ever more significant contributionto leveraging light constructionpotentials in modern passengercars. The heaviest individual component,the engine block, hasmeanwhile taken on a key role.If we consider the enormous numberof in-line engines produced –four-cylinder and recently alsothree-cylinder ones – the costbenefitaspect must have absolutepriority.The replacement ofgrey cast iron with aluminium forengine blocks therefore presupposeslow-cost concepts.Concept diversity for aluminiumengine blocksContrary to the engine blocks producedso far, mostly made from greycast iron based on a uniform conceptwhich already incorporatesthe cylinder bore surfaces when aperlitic structure configuration ischosen, there are many diverseoptions in the case of aluminium.These relate to the conceptmodules of type of engine blockdesign, alloy, casting method andcylinder bore surface, in which casemanifold incompatibilities haveto be taken into account. Theoverriding aspect is therefore thecompatibility of the conceptmodules. A further constraint forthe concepts which are viable inprinciple results for concreteengine development projects fromthe targets and general specificationswith respect to enginefunction, elemental engine characteristics(number and arrangementof cylinders), annual outputs, costsof castings (and whole base enginesystems), optimisation potential,environmental aspects andrecyclability. This situation hasled to a large number of marketableconcepts.Aluminium engine blocks andhigh-pressure die casting method■ Economic aspectFrom the economic aspect, formass produced engines, highlyautomated casting methods usingsand moulds (“core package process”)whose sequence time isnot bound to the solidification areprincipally competing with highpressuredie castings. In theespecially harshly contested, costsensitivemarket segment of fourcylinderengines, the latter castingmethod is unrivalled in the presentsituation with respect to costeffectiveness.■ Design featuresHigh-pressure die casting methodscompulsorily prescribe mouldabilityin steel. Hence the open deckdesign is mandatory. It is obvious,however, that with aluminiumengine blocks this design findsbetter general acceptance today.A distinctly reduced water jacketdepth and co-moulded cylinderbores have created a variant besidesthe conventional open deckwhich exhibits a sufficiently rigidcylinder area even without a closeddeck, meeting the requirements ofmost in-line engines. For nicheapplications in closed deck design,Movable Preform Casting Stationary die halfdie halfa suitable technology is availablein principle for developments inthe form of DOEHLERCORE, a corewithstanding high pressures andhigh thermal stress.■ PropertiesHigh-pressure die castings provideextremely accurate contours anddistinguish themselves by, incomparison, extremely narrowdimensional, shape and positiontolerances. It should be mentionedthat there are certain disadvantagesinherent in the shot-like diefilling. This leads to gas inclusions(microporosity) in the components.Moreover, a certain tendencytowards local shrinkage-cavityformation can hardly be eliminated.Because the gate always solidifiesin the course of this process, thereis no re-feeding possibility. On theother hand, pressure die castingsreach appreciable strength in thinwallareas. The high-pressure impactmakes for extremely fast heatdissipation. The structure near thesurface is therefore remarkablydense. Low-pore vacuum-assistedhigh-pressure die casting is anelaborate process with complexpressure casting dies for engineblocks, for engine blocks, but it ismore and more widely applied.GateCastingchamberMovabledie halfPreformCastingGateCastingchamberStationarydie halfDifferent gate systems of conventional high-pressure die casting (left) and vertical squeeze casting (right)