MAHLE Powertrain delivers new concept engine in less than 12 ...

MAHLE Powertrain delivers new concept engine in less than 12 ...

MAHLE Powertrain delivers new concept engine in less than 12 ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

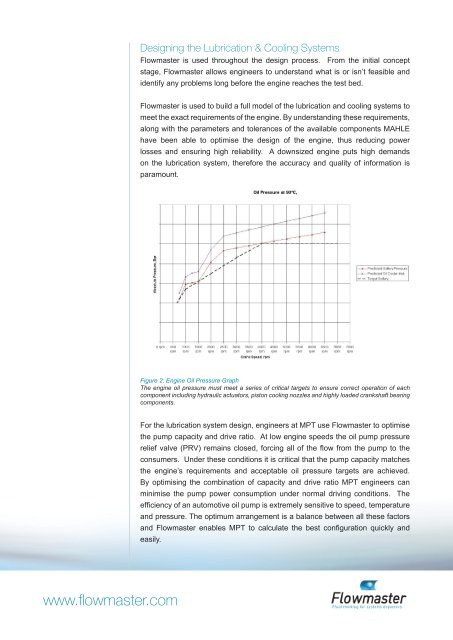

Design<strong>in</strong>g the Lubrication & Cool<strong>in</strong>g SystemsFlowmaster is used throughout the design process. From the <strong>in</strong>itial <strong>concept</strong>stage, Flowmaster allows <strong>eng<strong>in</strong>e</strong>ers to understand what is or isn’t feasible andidentify any problems long before the <strong>eng<strong>in</strong>e</strong> reaches the test bed.Flowmaster is used to build a full model of the lubrication and cool<strong>in</strong>g systems tomeet the exact requirements of the <strong>eng<strong>in</strong>e</strong>. By understand<strong>in</strong>g these requirements,along with the parameters and tolerances of the available components <strong>MAHLE</strong>have been able to optimise the design of the <strong>eng<strong>in</strong>e</strong>, thus reduc<strong>in</strong>g powerlosses and ensur<strong>in</strong>g high reliability. A downsized <strong>eng<strong>in</strong>e</strong> puts high demandson the lubrication system, therefore the accuracy and quality of <strong>in</strong>formation isparamount.Figure 2: Eng<strong>in</strong>e Oil Pressure GraphThe <strong>eng<strong>in</strong>e</strong> oil pressure must meet a series of critical targets to ensure correct operation of eachcomponent <strong>in</strong>clud<strong>in</strong>g hydraulic actuators, piston cool<strong>in</strong>g nozzles and highly loaded crankshaft bear<strong>in</strong>gcomponents.For the lubrication system design, <strong>eng<strong>in</strong>e</strong>ers at MPT use Flowmaster to optimisethe pump capacity and drive ratio. At low <strong>eng<strong>in</strong>e</strong> speeds the oil pump pressurerelief valve (PRV) rema<strong>in</strong>s closed, forc<strong>in</strong>g all of the flow from the pump to theconsumers. Under these conditions it is critical that the pump capacity matchesthe <strong>eng<strong>in</strong>e</strong>’s requirements and acceptable oil pressure targets are achieved.By optimis<strong>in</strong>g the comb<strong>in</strong>ation of capacity and drive ratio MPT <strong>eng<strong>in</strong>e</strong>ers canm<strong>in</strong>imise the pump power consumption under normal driv<strong>in</strong>g conditions. Theefficiency of an automotive oil pump is extremely sensitive to speed, temperatureand pressure. The optimum arrangement is a balance between all these factorsand Flowmaster enables MPT to calculate the best configuration quickly andeasily.www.flowmaster.com

![[PDF] Dust collector SFR-08 - mahle.com](https://img.yumpu.com/37394977/1/184x260/pdf-dust-collector-sfr-08-mahlecom.jpg?quality=85)