Ovens - RDM Industrial Services Ltd

Ovens - RDM Industrial Services Ltd

Ovens - RDM Industrial Services Ltd

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

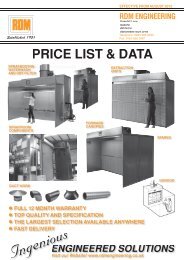

Please refer to the separate Price Guide Leafletsfor details of the Standard Product range.<strong>Ovens</strong> of any size can be produced.Customer support: <strong>RDM</strong> have been successfully providing service and spares since 1951. We employ experienced service andcommissioning engineers. Our engineers are based around the country to provide prompt service and support. <strong>RDM</strong> offer a varietyof on site service and routine maintenance programs.Control Options: <strong>RDM</strong> design and manufacture all of our control panels in-house. For this reason we employ people who fullyunderstand their operations and customers control requirements. Whatever the nature of your specific control or instrumentationrequirements, our electronics specialists will be able to manufacture a control system to suit.Choice of fuel source: <strong>RDM</strong>’s experience enables us to offer the most varied fuel sources possible. In direct heated ovens theburner fires directly into the recirculating hot air within an insulated heater Chamber. With Indirect, gas or fuel oil the burner firesinto a semi-sealed stainless steel heat exchanger over which the recirculating hot air passes. We also offer electric or steam heatedexchangers. Here again the elements are plugged into the insulated Heater chamber and the recirculating hot air is positivelypassed over the heat source to prevent heat stratifcation.Cruzeburn option: This is ideal for either, superb temperature stability or perhaps a widely varying choice of temperature controlrange. The system comprises of a sophisticated computer controlled temperature input device and a fully motorised fuel and airthrottle on the burner. The input device has twin digital displays, one display shows the actual Oven temperature, the other shows‘set point’ temperature. The computer sends a signal to the throttle motor and attempts to balance the infinitely variable heat outputto the load required. Within just a few minutes the controller ‘tunes’ the heat output to the actual oven heat load and then constantlytrims the heat output to finely balance any system changes.Feature Check list:•Choice of natural gas, propane, oil, steam or electric heating•Digital temperature controller•Accurate and stable heat control•All bolted construction – easily modified or moved•Galvanised and Stainless Steel construction.•High density mineral wool insulation•Fully insulated heater chambers and fans•Ample explosion relief panel work•Airsurround Air Seal System•Internal door release•Safe and adaptable control systems•Electronic over temperature protection device•External mounted fabricated steel doors•Infinite range of sizes and options•Full compliance with safety and environmental legislature•C.E. Marked and approved•Full on site installation and support serviceTypical Options:•CRUZEBURN self tuning modulating heater control system•Process control timer with audible/visual alarm•Paper or software output process chat recorders•Programmable ramp up/down control•24 Hour 7 Day time clock control•Humidity reduction via rotating wheel desiccant drier•Humidity addition via evaporative matrix•Refrigerated cooling mode system•Solenoid door locks•Door open/heater off control•Powered vertical lift doors with safety brakes•All Stainless Steel construction•Insulated floor•Integral conveyer systemsProduct development is continuous and <strong>RDM</strong> reserve the right to make alterations in specification and manufacture without notice.Products as delivered may therefore differ from that described in this document.<strong>RDM</strong> have 1000’s of satisfied Oven users.They include: Hawker Energy (Newport), St Bernard Composites(Farnborough), Ronaldsway Aircraft (I.O.M), Jaguar Cars (Coventry),Aston Martin (Gaydon), Henkel (Hatfield), Portacabin (York), City Group(Hemel), Tenmat (Manchester), Jubaili (Nigeria), Romageco (Kenya),Pilkington (St Helens), Balmoral Group (Aberdeen), CRP (Texas), PCDProducts (Hemel), Spirax (Cheltenham), David Brown (Huddersfield),Slingsby Aviation (York), Yuasa Batteries (S. Wales), Dudley Industries(Lytham), Covrad (Coventry), Indutek (Latvia), Terex (Coventry),Supersafe (Barcelona), Spring Active (Portugal), Zot Engineering(Edinburgh), Cummins (Stamford), Contour Aircraft (Cwmbran),Luccini (Manchester), Global Coatings (Saudi Arabia), Goltens (Dubai)Seos (Orlando), MTI (Bremen), Mitras (Northwich), Hi-Tech (Australia).NEW! Ultra Low CO 2 CRUZESAVE® Oven RangeSave around 30% on Energy costs and Carbon EmmissionsThese Oven feature:•Additional 150mm wall and roof insulation•Fully modulating and digitally controlled heaters•Invertor controlled circulation fans•Electronic Fume exhaust controls•Insulated Floor•PLC Controlled Auto-Doors on Tunnel <strong>Ovens</strong>All <strong>RDM</strong> <strong>Ovens</strong> are offered with a comprehensive 12 month warrantyas well as our Lifetime Service commitment backed by our 50 years ofEngineering Service Excellence. Manufactured to the highest QualityStandard ISO 9001 By: <strong>RDM</strong> <strong>Industrial</strong> <strong>Services</strong> <strong>Ltd</strong>.<strong>RDM</strong> <strong>Industrial</strong> <strong>Services</strong> <strong>Ltd</strong>.,Stakehill Lane,Middleton, Manchester. M24 2RY England.Tel: 44 (0)161 643 9333. Fax: 44 (0)161 655 3467.London Office: 44 (0)207 3209933sales@rdmengineering.co.uk www.rdmengineering.co.uk