Loading dock safety guide - Freight Transport Association

Loading dock safety guide - Freight Transport Association

Loading dock safety guide - Freight Transport Association

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

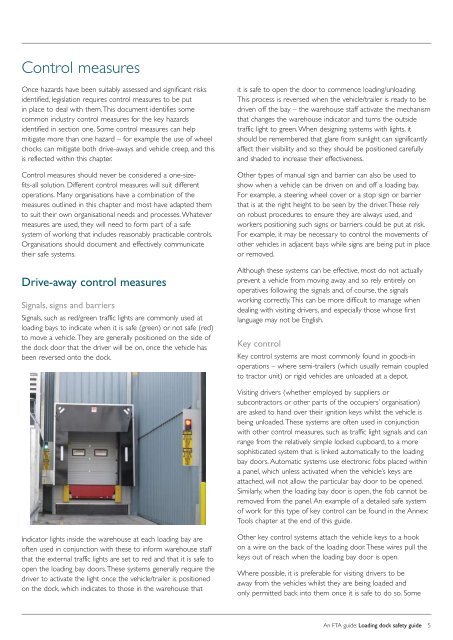

Control measuresOnce hazards have been suitably assessed and significant risksidentified, legislation requires control measures to be putin place to deal with them. This document identifies somecommon industry control measures for the key hazardsidentified in section one. Some control measures can helpmitigate more than one hazard – for example the use of wheelchocks can mitigate both drive-aways and vehicle creep, and thisis reflected within this chapter.Control measures should never be considered a one-sizefits-allsolution. Different control measures will suit differentoperations. Many organisations have a combination of themeasures outlined in this chapter and most have adapted themto suit their own organisational needs and processes. Whatevermeasures are used, they will need to form part of a safesystem of working that includes reasonably practicable controls.Organisations should document and effectively communicatetheir safe systems.Drive-away control measuresSignals, signs and barriersSignals, such as red/green traffic lights are commonly used atloading bays to indicate when it is safe (green) or not safe (red)to move a vehicle. They are generally positioned on the side ofthe <strong>dock</strong> door that the driver will be on, once the vehicle hasbeen reversed onto the <strong>dock</strong>.it is safe to open the door to commence loading/unloading.This process is reversed when the vehicle/trailer is ready to bedriven off the bay – the warehouse staff activate the mechanismthat changes the warehouse indicator and turns the outsidetraffic light to green. When designing systems with lights, itshould be remembered that glare from sunlight can significantlyaffect their visibility and so they should be positioned carefullyand shaded to increase their effectiveness.Other types of manual sign and barrier can also be used toshow when a vehicle can be driven on and off a loading bay.For example, a steering wheel cover or a stop sign or barrierthat is at the right height to be seen by the driver. These relyon robust procedures to ensure they are always used, andworkers positioning such signs or barriers could be put at risk.For example, it may be necessary to control the movements ofother vehicles in adjacent bays while signs are being put in placeor removed.Although these systems can be effective, most do not actuallyprevent a vehicle from moving away and so rely entirely onoperatives following the signals and, of course, the signalsworking correctly. This can be more difficult to manage whendealing with visiting drivers, and especially those whose firstlanguage may not be English.Key controlKey control systems are most commonly found in goods-inoperations – where semi-trailers (which usually remain coupledto tractor unit) or rigid vehicles are unloaded at a depot.Visiting drivers (whether employed by suppliers orsubcontractors or other parts of the occupiers’ organisation)are asked to hand over their ignition keys whilst the vehicle isbeing unloaded. These systems are often used in conjunctionwith other control measures, such as traffic light signals and canrange from the relatively simple locked cupboard, to a moresophisticated system that is linked automatically to the loadingbay doors. Automatic systems use electronic fobs placed withina panel, which unless activated when the vehicle’s keys areattached, will not allow the particular bay door to be opened.Similarly, when the loading bay door is open, the fob cannot beremoved from the panel. An example of a detailed safe systemof work for this type of key control can be found in the Annex:Tools chapter at the end of this <strong>guide</strong>.Indicator lights inside the warehouse at each loading bay areoften used in conjunction with these to inform warehouse staffthat the external traffic lights are set to red and that it is safe toopen the loading bay doors. These systems generally require thedriver to activate the light once the vehicle/trailer is positionedon the <strong>dock</strong>, which indicates to those in the warehouse thatOther key control systems attach the vehicle keys to a hookon a wire on the back of the loading door. These wires pull thekeys out of reach when the loading bay door is open.Where possible, it is preferable for visiting drivers to beaway from the vehicles whilst they are being loaded andonly permitted back into them once it is safe to do so. SomeAn FTA <strong>guide</strong>: <strong>Loading</strong> <strong>dock</strong> <strong>safety</strong> <strong>guide</strong> 5