TBM 29 - and - Merkel Freudenberg

TBM 29 - and - Merkel Freudenberg

TBM 29 - and - Merkel Freudenberg

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

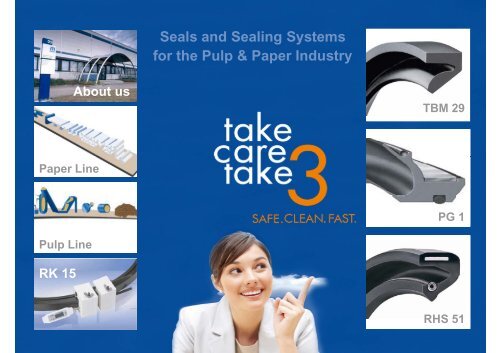

Paper Line<br />

Pulp Line<br />

RK 15<br />

About us<br />

Seals <strong>and</strong> Sealing Systems<br />

for the Pulp & Paper Industry<br />

<strong>TBM</strong> <strong>29</strong><br />

PG 1<br />

RHS 51

<strong>Merkel</strong> <strong>Freudenberg</strong> g Fluidtechnic<br />

Sealing specialist from Hamburg<br />

�� FFounded d d 1849 iin WWeinheim, i h i �� Founded 1899 in Hannover<br />

<strong>and</strong> still family owned today<br />

� 400 employees<br />

� Approx. 32.000 employees /<br />

441 companies worldwide<br />

� Turnover 2010: 45,3 M€<br />

� Turnover 2010: 4,8 billion€<br />

Production<br />

Sales<br />

Production <strong>and</strong> Sales<br />

<strong>Merkel</strong> within the <strong>Freudenberg</strong> Group is a worldwide operating specialist for innovative seals<br />

<strong>and</strong> sealing g systems y in the heavy y industry. y<br />

2

<strong>Merkel</strong> <strong>Freudenberg</strong> g Fluidtechnic<br />

Historic milestones<br />

3<br />

1899 Founded by Heinrich Martin <strong>Merkel</strong><br />

19<strong>29</strong><br />

1952<br />

First seal made of elastomeric material<br />

First production of PTFE seals in Germany<br />

1975 Launching of polyurethane seal production<br />

1988<br />

First seal with an outer diameter of over 10 m<br />

1996 Becoming eco g pa part t oof tthe e <strong>Freudenberg</strong> eude be g Group G oup<br />

Today, <strong>Merkel</strong> is the technology leader for the heavy industry

Particular Strengths g<br />

What makes <strong>Merkel</strong> different?<br />

Advisory competence: We are at your side.<br />

Our staff of dedicated engineers with years of experience are there for you, any time you need it.<br />

Development competence: We don‘t leave anything to chance.<br />

Test plus FEA Layout Layout-Programmes<br />

Programmes<br />

The “right” right Product<br />

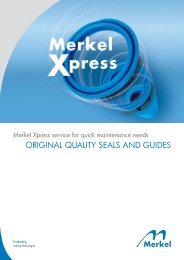

<strong>Merkel</strong> Xpress: 24 hours just-in-time service worldwide<br />

Tailor-made seals, made of OEM materials – if there is a need for speed.<br />

4

We Ask Our Customers<br />

Customer satisfaction analysis 2010 – external market research<br />

On the following points . . .<br />

5<br />

� Advisory competence<br />

� Functionality y of products p<br />

� Innovation<br />

� Customer support<br />

� Response to inquiries<br />

� Special dem<strong>and</strong>s<br />

��<br />

. . .<br />

Mr. Faßbender,<br />

Herrenknecht AG<br />

Mr. Hausler,<br />

Dieffenbacher GmbH & Co.<br />

. . . our customers value us to be stronger than our competitors.

Market Allocation into Market Segments g<br />

Heavy Industry<br />

Shi Ship PPresses<br />

Metal<br />

Pulp & Paper<br />

Wind<br />

Tunnel Boring Mining Civil Engineering<br />

<strong>Merkel</strong> – as the leading supplier – offers sealing solutions for the most challenging<br />

heavy industry applications. Market leaders rely on our product quality.<br />

6

<strong>Merkel</strong> Seals in Paper p Manufacture<br />

High-performance seals for the production process as a whole<br />

7

Main a Products oducts for o the t e Pulp u p Linee<br />

Rotary shaft seals <strong>and</strong> packings<br />

8<br />

Packings <strong>TBM</strong> <strong>29</strong><br />

Enviromatic EA

<strong>Merkel</strong> Tubomatic - <strong>TBM</strong> <strong>29</strong> Profile<br />

Main properties – Your benefit<br />

Main properties of the <strong>Merkel</strong> Tubomatic <strong>TBM</strong> <strong>29</strong> . . .<br />

� endlessly vulcanized element from mould<br />

� proven, robust design in various applications<br />

� allowed shaft misalignment/eccentricity: ± 3 mm<br />

� compatibility with aggressive media<br />

. . . <strong>and</strong> your benefits<br />

9<br />

� reliable performance, best leakage behaviour<br />

� lifetime of seal matches with maintenance cycle<br />

– no unplanned stops<br />

� mounting ti on site it (if necessary) )<br />

with hot bonding set

<strong>Merkel</strong> Tubomatic - <strong>TBM</strong> <strong>29</strong> Profile<br />

Successful field experiences in the pulp production<br />

Motivation:<br />

A washing press on site showed a not acceptable<br />

leakage rate. The competitor solution revealed<br />

heavy scoring at the sealing lip <strong>and</strong> sleeve.<br />

<strong>Merkel</strong> Solution:<br />

10<br />

Special operating conditions:<br />

� Aggressive media (Black liquor<br />

sodium hydroxide)<br />

pH: 10 to 11<br />

� Temperature: +80°C to +90°C<br />

�� Circumferential speeds: 30 30-50 50 rpm<br />

Profile<br />

Result:<br />

�� First seal that performs leakage<br />

free in this application since<br />

May 2010

<strong>Merkel</strong> Enviromatic EA<br />

Main properties – Your benefit<br />

Main properties of the <strong>Merkel</strong> Enviromatic EA<br />

� FEA calculated seal design: uniform contact pressure<br />

<strong>and</strong> small contact area of the seal lip even at large<br />

axial clearances<br />

� Strong sealing lip with defined, sharp sealing edge<br />

�� Hi High h wiping i i <strong>and</strong> d sealing li effect ff t against i t environmental<br />

i t l<br />

conditions<br />

. . . <strong>and</strong> your benefits<br />

�� reliable reliable, defined wiping performance<br />

� outst<strong>and</strong>ing resistance to ageing, fluids <strong>and</strong> ozone<br />

� high wear resistance for long lifetime<br />

�� di diameters t up to t Ø 3000 mm<br />

� easy replacement – matches housings type A<br />

11

Main Products for the Paper p Line<br />

Rotary shaft seals <strong>and</strong> special products<br />

12<br />

<strong>Merkel</strong> RHS 51 NOK SBR<br />

<strong>Merkel</strong> R 35<br />

<strong>Merkel</strong> Paperguard Further products

<strong>Merkel</strong> Radiamatic RHS 51 – High g Performance Radial Shaft Seal<br />

Main properties – Your benefit<br />

Main properties of the <strong>Merkel</strong> Radiamatic RHS 51 . . .<br />

� highly wear & tear resistant<br />

� circumferential speeds up to 35 m/s<br />

� equal lip load in case of high shaft misalignment<br />

� secure self-retaining fit<br />

� excellent sealing function on the static side<br />

. . . <strong>and</strong> your benefits<br />

13<br />

� reliable, leakage-free performance<br />

� new benchmark in production speed possible<br />

� low cost for maintenance of counter surfaces<br />

� easy mounting & dismounting – no damage to the housing<br />

� can be used more than once

Evenly y Spread p Radial Forces at High g Eccentricities<br />

Optimised seal design for rotary applications<br />

Contact Normal Streess<br />

14<br />

2<br />

1,8<br />

1,6<br />

1,4<br />

1,2<br />

1<br />

0,8<br />

0,6<br />

04 0,4<br />

0,2<br />

-3 mm<br />

0<br />

0,25 0,55 0,85 1,15<br />

Arc Length<br />

1,45 1,75<br />

Radial force = 50%<br />

Contact Normal Streess<br />

2<br />

1,8<br />

1,6<br />

1,4<br />

1,2<br />

1<br />

0,8<br />

0,6<br />

04 0,4<br />

0,2<br />

Nominal Diameter<br />

The space covered<br />

by the function line<br />

is equivalent to the<br />

radial force<br />

0<br />

0,25 0,55 0,85 1,15 1,45 1,75<br />

Arc Length<br />

Radial force at nominal position = 100 %<br />

+ 3 mm<br />

Contact Normal Streess<br />

2<br />

1,8<br />

1,6<br />

1,4<br />

1,2<br />

1<br />

0,8<br />

0,6<br />

04 0,4<br />

0,2<br />

0<br />

0,25 0,55 0,85 1,15 1,45 1,75<br />

Arc Length<br />

Radial force = 135 %

<strong>Merkel</strong> Radiamatic Radial Shaft Seals<br />

Easy mounting<br />

15<br />

� No special mounting tools necessary<br />

� Excellent sealing function on the static side<br />

� No damage to the housing

<strong>Merkel</strong> Radiamatic RHS 51 – High g Performance Radial Shaft Seal<br />

Field experiences – Paper production<br />

Motivation:<br />

Leakage 70l/day in press section <strong>and</strong> competitor seals<br />

were burned by friction <strong>and</strong> heat.<br />

<strong>Merkel</strong> Solution: RHS 51<br />

16<br />

Special operating conditions:<br />

� Radial shaft off set<br />

up to 3 mm<br />

� Aggressive media<br />

� Temperature resistance<br />

up to 1150°C 0°C<br />

� Circumferential speeds<br />

up to 35 m/s<br />

�� WWorn-out t counter t surfaces f<br />

Result:<br />

� Leakage-free performance<br />

since installation

<strong>Merkel</strong> Radiamatic R 35 – With Rubber Lock<br />

Main properties – Your benefit<br />

Main properties of the <strong>Merkel</strong> Radiamatic R 35 . . .<br />

� Endlessly vulcanized element from mould<br />

with stainless spring<br />

�� Wid Wide range of f diameters di t from f 200 mm up to t 3500 mm<br />

� Can st<strong>and</strong> pressures up to 0,05 MPa<br />

� 3 St<strong>and</strong>ard seal materials: NRB, , HNBR <strong>and</strong> FKM<br />

. . . <strong>and</strong> your benefits<br />

17<br />

� reliable, leakage free performance<br />

� easy mounting on site without disassembling the cylinder<br />

� full rubber seal – no damage of the housing during replacement

<strong>Merkel</strong> Bonding g Set RK 15 for Radiamatic R 35<br />

Secure <strong>and</strong> lasting bonding of radial shaft seals on site<br />

<strong>Merkel</strong> Bonding Set<br />

Installation steps<br />

18<br />

Features<br />

� Robust synthetic material device<br />

for multiple use<br />

�� MMatched t h d tto product d t <strong>and</strong> d application li ti<br />

� Easy h<strong>and</strong>ling at any location<br />

of the shaft

<strong>Merkel</strong> Radiamatic R 35 – With Rubber Lock<br />

Field experiences<br />

Motivation:<br />

Special operating conditions:<br />

Search for a sealing system able to be mounted on site<br />

without the necessity to disassemble the main shaft. shaft � High g reliability y<br />

Replacement of existing seal on site by <strong>Merkel</strong> sealing<br />

solution.<br />

<strong>Merkel</strong> Solution:<br />

19<br />

Cutting area of the ring:<br />

Cotton-fabric-free zone,<br />

suitable for RK 15 Bonding Set<br />

� Requested lifetime: 20 years<br />

Result:<br />

� Perfect performance<br />

� Flexibility e b ty for o tthe e custo customer e<br />

to mount high quality<br />

sealing solutions on site.

<strong>Merkel</strong> Paperguard p g PG 1– High g Performing g Safeguard g<br />

Main Properties – Your Benefit<br />

Main properties of the <strong>Merkel</strong> Paperguard PG 1 . . .<br />

�Stable �Stable functional reliability due to additional spring<br />

at sealing lip <strong>and</strong> secondary sealing edge<br />

�Minimum amount of wear <strong>and</strong> tear<br />

�High �High resistance to elevated temperatures<br />

. . . <strong>and</strong> your benefits<br />

20<br />

�No �No loss of lubricant – perfect protection of he<br />

product <strong>and</strong> the environment<br />

�Easy mounting due to split version<br />

�Stable �Stable long-term long term behaviour<br />

�Extended service intervals

NOK SBR<br />

Main properties – Your benefit<br />

Main properties of the NOK SBR . . .<br />

� highly wear & tear resistant<br />

� low friction heat<br />

� secure self-retaining fit (steel cage)<br />

� reliable sealing performance<br />

. . . <strong>and</strong> your benefits<br />

21<br />

� reliable, leakage-free performance<br />

� huge st<strong>and</strong>ard programme<br />

� long service life