download a PDF of the full March 2011 issue - Wattnow

download a PDF of the full March 2011 issue - Wattnow

download a PDF of the full March 2011 issue - Wattnow

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

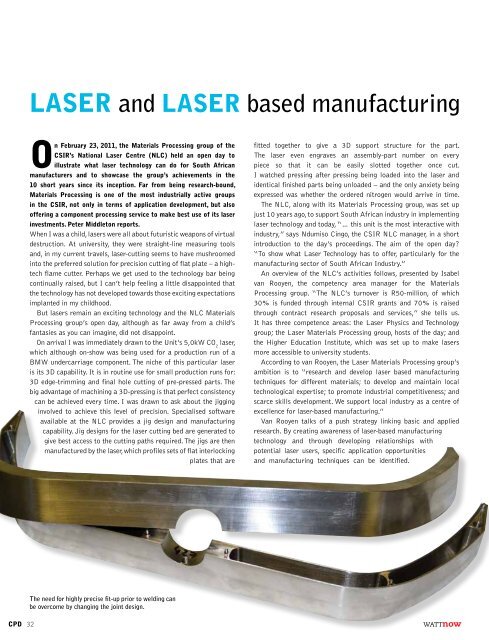

LASER and LASER based manufacturingOn February 23, <strong>2011</strong>, <strong>the</strong> Materials Processing group <strong>of</strong> <strong>the</strong>CSIR’s National Laser Centre (NLC) held an open day toillustrate what laser technology can do for South Africanmanufacturers and to showcase <strong>the</strong> group’s achievements in <strong>the</strong>10 short years since its inception. Far from being research-bound,Materials Processing is one <strong>of</strong> <strong>the</strong> most industrially active groupsin <strong>the</strong> CSIR, not only in terms <strong>of</strong> application development, but also<strong>of</strong>fering a component processing service to make best use <strong>of</strong> its laserinvestments. Peter Middleton reports.When I was a child, lasers were all about futuristic weapons <strong>of</strong> virtualdestruction. At university, <strong>the</strong>y were straight-line measuring toolsand, in my current travels, laser-cutting seems to have mushroomedinto <strong>the</strong> preferred solution for precision cutting <strong>of</strong> flat plate – a hightechflame cutter. Perhaps we get used to <strong>the</strong> technology bar beingcontinually raised, but I can’t help feeling a little disappointed that<strong>the</strong> technology has not developed towards those exciting expectationsimplanted in my childhood.But lasers remain an exciting technology and <strong>the</strong> NLC MaterialsProcessing group’s open day, although as far away from a child’sfantasies as you can imagine, did not disappoint.On arrival I was immediately drawn to <strong>the</strong> Unit’s 5,0kW CO 2laser,which although on-show was being used for a production run <strong>of</strong> aBMW undercarriage component. The niche <strong>of</strong> this particular laseris its 3D capability. It is in routine use for small production runs for:3D edge-trimming and final hole cutting <strong>of</strong> pre-pressed parts. Thebig advantage <strong>of</strong> machining a 3D-pressing is that perfect consistencycan be achieved every time. I was drawn to ask about <strong>the</strong> jigginginvolved to achieve this level <strong>of</strong> precision. Specialised s<strong>of</strong>twareavailable at <strong>the</strong> NLC provides a jig design and manufacturingcapability. Jig designs for <strong>the</strong> laser cutting bed are generated togive best access to <strong>the</strong> cutting paths required. The jigs are <strong>the</strong>nmanufactured by <strong>the</strong> laser, which pr<strong>of</strong>iles sets <strong>of</strong> flat interlockingplates that arefitted toge<strong>the</strong>r to give a 3D support structure for <strong>the</strong> part.The laser even engraves an assembly-part number on everypiece so that it can be easily slotted toge<strong>the</strong>r once cut.I watched pressing after pressing being loaded into <strong>the</strong> laser andidentical finished parts being unloaded – and <strong>the</strong> only anxiety beingexpressed was whe<strong>the</strong>r <strong>the</strong> ordered nitrogen would arrive in time.The NLC, along with its Materials Processing group, was set upjust 10 years ago, to support South African industry in implementinglaser technology and today, “… this unit is <strong>the</strong> most interactive withindustry,” says Ndumiso Cingo, <strong>the</strong> CSIR NLC manager, in a shortintroduction to <strong>the</strong> day’s proceedings. The aim <strong>of</strong> <strong>the</strong> open day?“To show what Laser Technology has to <strong>of</strong>fer, particularly for <strong>the</strong>manufacturing sector <strong>of</strong> South African Industry.”An overview <strong>of</strong> <strong>the</strong> NLC’s activities follows, presented by Isabelvan Rooyen, <strong>the</strong> competency area manager for <strong>the</strong> MaterialsProcessing group. “The NLC’s turnover is R50-million, <strong>of</strong> which30% is funded through internal CSIR grants and 70% is raisedthrough contract research proposals and services,” she tells us.It has three competence areas: <strong>the</strong> Laser Physics and Technologygroup; <strong>the</strong> Laser Materials Processing group, hosts <strong>of</strong> <strong>the</strong> day; and<strong>the</strong> Higher Education Institute, which was set up to make lasersmore accessible to university students.According to van Rooyen, <strong>the</strong> Laser Materials Processing group’sambition is to “research and develop laser based manufacturingtechniques for different materials; to develop and maintain localtechnological expertise; to promote industrial competitiveness; andscarce skills development. We support local industry as a centre <strong>of</strong>excellence for laser-based manufacturing.”Van Rooyen talks <strong>of</strong> a push strategy linking basic and appliedresearch. By creating awareness <strong>of</strong> laser-based manufacturingtechnology and through developing relationships withpotential laser users, specific application opportunitiesand manufacturing techniques can be identified.The need for highly precise fit-up prior to welding canbe overcome by changing <strong>the</strong> joint design.32