Syngas Production and Conversion to Products - The Catalyst Group

Syngas Production and Conversion to Products - The Catalyst Group

Syngas Production and Conversion to Products - The Catalyst Group

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

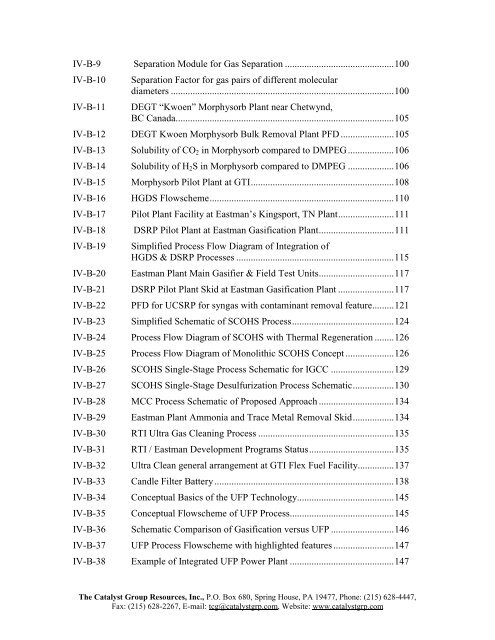

IV-B-9 Separation Module for Gas Separation .............................................100IV-B-10 Separation Fac<strong>to</strong>r for gas pairs of different moleculardiameters ............................................................................................100IV-B-11 DEGT “Kwoen” Morphysorb Plant near Chetwynd,BC Canada..........................................................................................105IV-B-12 DEGT Kwoen Morphysorb Bulk Removal Plant PFD ......................105IV-B-13 Solubility of CO 2 in Morphysorb compared <strong>to</strong> DMPEG ...................106IV-B-14 Solubility of H 2 S in Morphysorb compared <strong>to</strong> DMPEG ...................106IV-B-15 Morphysorb Pilot Plant at GTI...........................................................108IV-B-16 HGDS Flowscheme............................................................................110IV-B-17 Pilot Plant Facility at Eastman’s Kingsport, TN Plant.......................111IV-B-18 DSRP Pilot Plant at Eastman Gasification Plant...............................111IV-B-19 Simplified Process Flow Diagram of Integration ofHGDS & DSRP Processes .................................................................115IV-B-20 Eastman Plant Main Gasifier & Field Test Units...............................117IV-B-21 DSRP Pilot Plant Skid at Eastman Gasification Plant .......................117IV-B-22 PFD for UCSRP for syngas with contaminant removal feature.........121IV-B-23 Simplified Schematic of SCOHS Process..........................................124IV-B-24 Process Flow Diagram of SCOHS with <strong>The</strong>rmal Regeneration ........126IV-B-25 Process Flow Diagram of Monolithic SCOHS Concept ....................126IV-B-26 SCOHS Single-Stage Process Schematic for IGCC ..........................129IV-B-27 SCOHS Single-Stage Desulfurization Process Schematic.................130IV-B-28 MCC Process Schematic of Proposed Approach ...............................134IV-B-29 Eastman Plant Ammonia <strong>and</strong> Trace Metal Removal Skid.................134IV-B-30 RTI Ultra Gas Cleaning Process ........................................................135IV-B-31 RTI / Eastman Development Programs Status...................................135IV-B-32 Ultra Clean general arrangement at GTI Flex Fuel Facility...............137IV-B-33 C<strong>and</strong>le Filter Battery ..........................................................................138IV-B-34 Conceptual Basics of the UFP Technology........................................145IV-B-35 Conceptual Flowscheme of UFP Process...........................................145IV-B-36 Schematic Comparison of Gasification versus UFP ..........................146IV-B-37 UFP Process Flowscheme with highlighted features .........................147IV-B-38 Example of Integrated UFP Power Plant ...........................................147<strong>The</strong> <strong>Catalyst</strong> <strong>Group</strong> Resources, Inc., P.O. Box 680, Spring House, PA 19477, Phone: (215) 628-4447,Fax: (215) 628-2267, E-mail: tcg@catalystgrp.com, Website: www.catalystgrp.com