American Handgunner May/June 1977

American Handgunner May/June 1977

American Handgunner May/June 1977

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

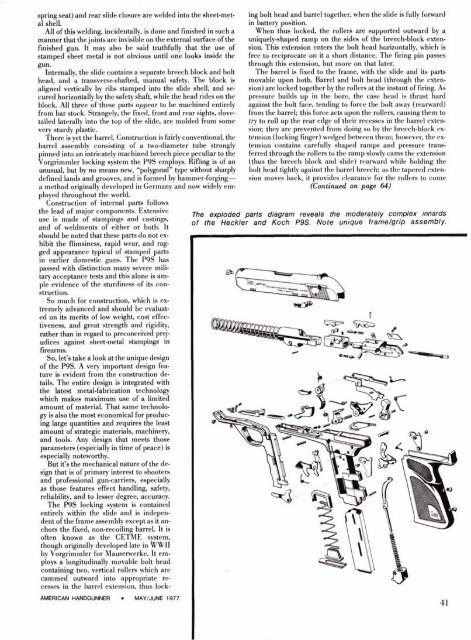

spring seat) and rear slide closure are welded into the sheet-meta1shell.All of this welding, incidentally, is done and finished in such amanner that the joints are invisible on the external surface of thefinished gun. It may also be said truthfully that the use ofstamped sheet metal is not obvious until one looks inside thegun.Internally, the slide contains a separate breech block and bolthead, and a transverse-shafted, manual safety. The block isaligned vertically by ribs stamped into the slide shell, and securedhorizontally by the safety shaft, while the head rides on theblock. All three of'these parts appear to be machined entirelyfrom bar stock. Strangely, the fixed, front and rear sights, dovetailedlaterally into the top of the slide, are molded from somevery sturdy plastic.There is yet the barrel. Construction is fairly conventional, thebarrel assembly consisting of a two-diameter tube stronglypinned into an intricately machined breech piece peculiar to theVorgrimmler locking system the P9S employs. Rifling is of anunusual, but by no means new, "polygonal" type without sharplydefined lands and grooves, and is formed by hammer-forgingamethod originally developed in Germany and now widely employedthroughout the world.Construction of internal parts followsthe lead of major components. Extensiveuse is made of stampihgs and castings,and of weldments of either or both. Itshould be noted that these parts do not exhibitthe flimsiness, rapid wear, and raggedappearance typical of stamped partsin earlier domestic guns. The P9S haspassed with distinction many severe militaryacceptance tests and this alone is ampleevidence of the sturdiness of its construction.So much for construction, which is extremelyadvanced and should be evaluatedon its merits of low weight, cost effectiveness,and great strength and rigidity,rather than in regard to reconceived prejudicesagainst sheet-metal stampings infirearms.So, let's take a look at the unique designof the P9S. A very important design featureis evident from the construction details.The entire design is integrated withthe latest metal-fabrication technologywhich makes maximum use of a limitedamount of material. That same technologyis also the most economical for producinglarge quantities and requires the leastamount of strategic materials, machinery,and tools. Any design that meets thoseparameters (especially in time of ~eace) isespecially noteworthy.But it's the mechanical nature of the designthat is of primary interest to shootersand professional gun-carriers, especiallyas those features effect handling, safety,reliability, and to lesser degree, accuracy.The P9S locking system is containedentirely within the slide and is independentof the frame assembly except as it anchorsthe fixed, non-recoiling barrel. It isoften known as the CETME system,though originally developed late in WWIIby Vorgrimmler for Mauserwerke. It employsa longitudinally movable bolt headcontaining two, vertical rollers which arecammed outward into appropriate recessesin the barrel extension, thus lock-AMERICAN HANDGUNNER * MAY/JUNE 197ing bolt head and barrel together, when the slide is fully forwardin battery position.When thus locked, the rollers are supported outward by auniquely-shaped ramp on the sides of the breech-block extension.This extension enters the bolt head horizontally, which isfree to reciprocate on it a short distance. The firing pin passesthrough this extension, but more on that later.The barrel is fixed to the frame, with the slide and its pansmovable upon both. Barrel and bolt head (through the extension)are locked together by the rollers at the instant of firing. Aspressure builds up in the bore, the case head is thrust hardagainst the bolt face, tending to force the bolt away (rearward)from the barrel; this force acts upon the rollers, causing them totry to roll up the rear edge of their recesses in the barrel extension;they are prevented from doing so by the breech-block extension(locking finger) wedged between them; however, the extensioncontains carefully shaped ramps and pressure transferredthrough the rollers to the ramp slowly cams the extension(thus the breech block and slide) rearward while holding thebolt head tightly against the barrel breech; as the tapered extensionmoves back, it provides clearance for the rollers to come(Continued on page 64)The exploded parts diagram reveals the moderately complex innardsof the Heckler and Koch P9S. Note unique frame/grip assembly.