CH260-CH440 Service Manual - Kohler Engines

CH260-CH440 Service Manual - Kohler Engines

CH260-CH440 Service Manual - Kohler Engines

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

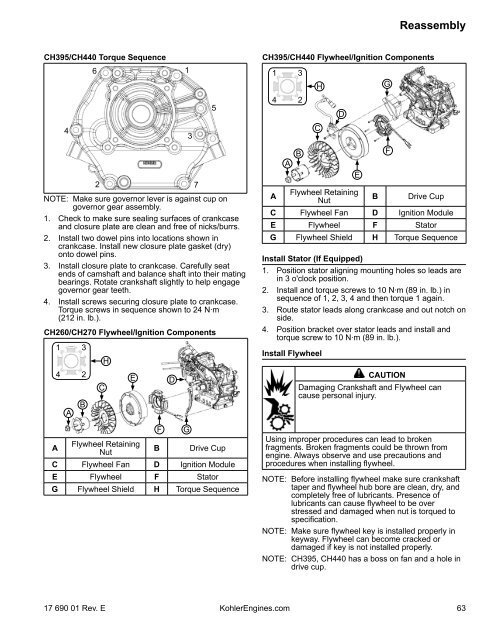

ReassemblyCH395/<strong>CH440</strong> Torque SequenceCH395/<strong>CH440</strong> Flywheel/Ignition Components6113HG542D43C2NOTE: Make sure governor lever is against cup ongovernor gear assembly.1. Check to make sure sealing surfaces of crankcaseand closure plate are clean and free of nicks/burrs.2. Install two dowel pins into locations shown incrankcase. Install new closure plate gasket (dry)onto dowel pins.3. Install closure plate to crankcase. Carefully seatends of camshaft and balance shaft into their matingbearings. Rotate crankshaft slightly to help engagegovernor gear teeth.4. Install screws securing closure plate to crankcase.Torque screws in sequence shown to 24 N·m(212 in. lb.).<strong>CH260</strong>/CH270 Flywheel/Ignition Components14A32BCHEAFlywheel RetainingNutB Drive CupC Flywheel Fan D Ignition ModuleE Flywheel F StatorG Flywheel Shield H Torque SequenceFDG7ABEAFlywheel RetainingNutB Drive CupC Flywheel Fan D Ignition ModuleE Flywheel F StatorG Flywheel Shield H Torque SequenceInstall Stator (If Equipped)1. Position stator aligning mounting holes so leads arein 3 o'clock position.2. Install and torque screws to 10 N·m (89 in. lb.) insequence of 1, 2, 3, 4 and then torque 1 again.3. Route stator leads along crankcase and out notch onside.4. Position bracket over stator leads and install andtorque screw to 10 N·m (89 in. lb.).Install FlywheelCAUTIONDamaging Crankshaft and Flywheel cancause personal injury.Using improper procedures can lead to brokenfragments. Broken fragments could be thrown fromengine. Always observe and use precautions andprocedures when installing flywheel.NOTE: Before installing flywheel make sure crankshafttaper and flywheel hub bore are clean, dry, andcompletely free of lubricants. Presence oflubricants can cause flywheel to be overstressed and damaged when nut is torqued tospecification.NOTE: Make sure flywheel key is installed properly inkeyway. Flywheel can become cracked ordamaged if key is not installed properly.NOTE: CH395, <strong>CH440</strong> has a boss on fan and a hole indrive cup.F17 690 01 Rev. E <strong>Kohler</strong><strong>Engines</strong>.com63