Winter 2003 - Tinius Olsen

Winter 2003 - Tinius Olsen

Winter 2003 - Tinius Olsen

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

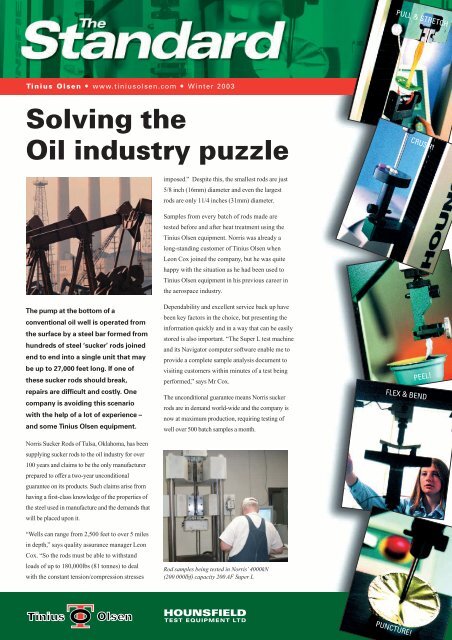

PULL & STRETCH<strong>Tinius</strong> <strong>Olsen</strong> • www.tiniusolsen.com • <strong>Winter</strong> <strong>2003</strong>Solving theOil industry puzzleCRUSH!imposed.” Despite this, the smallest rods are just5/8 inch (16mm) diameter and even the largestrods are only 11/4 inches (31mm) diameter.Samples from every batch of rods made aretested before and after heat treatment using the<strong>Tinius</strong> <strong>Olsen</strong> equipment. Norris was already along-standing customer of <strong>Tinius</strong> <strong>Olsen</strong> whenLeon Cox joined the company, but he was quitehappy with the situation as he had been used to<strong>Tinius</strong> <strong>Olsen</strong> equipment in his previous career inthe aerospace industry.The pump at the bottom of aconventional oil well is operated fromthe surface by a steel bar formed fromhundreds of steel ‘sucker’ rods joinedend to end into a single unit that maybe up to 27,000 feet long. If one ofthese sucker rods should break,repairs are difficult and costly. Onecompany is avoiding this scenariowith the help of a lot of experience –and some <strong>Tinius</strong> <strong>Olsen</strong> equipment.Dependability and excellent service back up havebeen key factors in the choice, but presenting theinformation quickly and in a way that can be easilystored is also important. “The Super L test machineand its Navigator computer software enable me toprovide a complete sample analysis document tovisiting customers within minutes of a test beingperformed,” says Mr Cox.The unconditional guarantee means Norris suckerrods are in demand world-wide and the company isnow at maximum production, requiring testing ofwell over 500 batch samples a month.PEEL!FLEX & BENDNorris Sucker Rods of Tulsa, Oklahoma, has beensupplying sucker rods to the oil industry for over100 years and claims to be the only manufacturerprepared to offer a two-year unconditionalguarantee on its products. Such claims arise fromhaving a first-class knowledge of the properties ofthe steel used in manufacture and the demands thatwill be placed upon it.“Wells can range from 2,500 feet to over 5 milesin depth,” says quality assurance manager LeonCox. “So the rods must be able to withstandloads of up to 180,000lbs (81 tonnes) to dealwith the constant tension/compression stressesRod samples being tested in Norris’4000kN(200 000lbf) capacity 200 AF Super LHOUNSFIELDTEST EQUIPMENT LTDPUNCTURE!

Food TestingMachineCheck out our newweb siteWith plans well advanced for the name change from Hounsfield to Tinus <strong>Olsen</strong>in January, a revised Hounsfield web site will continue to operate for the timebeing, but visitors should also take a look at the main site, www.tiniusolsen.com.This has also been redesigned to make it more useful and helpful to materialstesting professionals.The growing demand for analysis offood textures has led <strong>Tinius</strong> <strong>Olsen</strong>/Hounsfield to introduce a new testmachine specially developed to meetthe needs of the food industry.The new model, designated H1KF, featuressurgical grade stainless steel construction for easycleaning and is ideal for common texture tests suchas TPA, puncture, back extrusion, deformation,snap, puncture, shear, extrusion and other textureanalysis tests on applications up to 1kN (200 lbf).It can be fitted with a variety of grips, probes andcells for food testing – and when combined withthe company’s powerful testing software, itbecomes a flexible yet robust testing stationideally suited to the unique needs of the industry.www.tiniusolsen.comOne of the most obvious features from the homepage is that visitors can choose to search byproduct or industry sector, with either routetaking you quickly to the information needed.The news and events section includes currentinformation on exhibitions where the company isrepresented, while the ‘Calibration Services’ and‘Resource Center’ pages provide usefulbackground and contact information on suchthings as associations and standardsorganisations, as well as offering brochures indownloadable PDF format.If you’re looking for some additional equipmentbut funds are strictly limited, it could be worthchecking the used equipment section on aregular basis or registering your interests withyour local representative – who of course can befound through the ‘Contact Us’ page.Diary dates – Where to see us this yearAs we go to press there are currently two major events where <strong>Tinius</strong> <strong>Olsen</strong>/Hounsfieldwill be present - but don't forget to check for details of forthcoming events regularlyupdated at www.tiniusolsen.comNov 25 - 28Jan 6 - 8Rich MacChemical and laboratory exhibition, Milan, ItalyPlastecPlastics industry show, Anaheim, California, USA. Incorporating Electronics West,Medical Design and Manufacturing West, Pacific Design and ManufacturingThe use of stainless steel makes cleaningthe H1KF a simple operation2

Sent to the Tower!In times past, being ‘sent to the Tower of London’ was not an encouragingprospect, but UK sales manager Steve Taylor enjoyed an altogether happierexperience when he delivered an H25KS test machineKnown world-wide for its Yeoman Warders(Beefeaters) and as the place where the CrownJewels are kept, the Tower of London attractsthousands of tourists every year. Yet its appeal isnow used to encourage learning amongst thehundreds of children who attend on visits withtheir schools. A teaching programme for historyis well established and this year the Tower hasalso begun a science programme.Science education officer Mandy Martin-Smithexplains: “One of the keys to science educationis to develop children’s interest in the subjectfrom an early age. We let them examine and tryon various items from the Royal Amouries andthen compare historic armour with modernbody protection.”<strong>Tinius</strong> <strong>Olsen</strong>/Hounsfield’s H25KS test machine,complete with QMAT Pro software, introducesthe children to materials science by testing therelative strengths of metal ‘armour’ againstmaterials such as Kevlar. “The children try onsixteenth century armour, but cutting it up forTesting ‘armour’at the Tower of Londonwith the H25KStesting is definitely not allowed!” says Mandy.Metal samples are used as a substitute butobtaining test samples of modern materials cansometimes be equally challenging, she adds.The programme is open to school groups fromthe UK and overseas and is proving popular withteachers and children alike. Running the schemerelies on companies like <strong>Tinius</strong><strong>Olsen</strong>/Hounsfield for support. They have beenreally great,” says Mandy. “What we need now issomeone who can provide us with a PC…”New equipment for plasticsFollowing hard on the heels of launchingimpact testers for the UK and Europeanmarkets, <strong>Tinius</strong> <strong>Olsen</strong>’s developmentprogramme for the plastics sectorcontinues apace with the introductionworld-wide of a new heat deflection andVicat tester.Although this is not the first machine of its kindto be offered by the company, technicaldevelopments have allowed more features to beincorporated, resulting in a machine that is easierto use and offers improved reading and reporting.The 603 HDTM (Heat Deflection and VicatTesting Machine) benefits from precisioncontrol electronics originally developed for thehigh force testing machines and torsion testers.Improvements in terminal and displaytechnology have also been adopted andmodified to suit the 603. Other benefits of thenew machine include the development of apneumatic station lifting system that raises allstations from the hot oil bath at the touch of abutton. The station lift also incorporates aspecimen basket to catch any samples thatbecome dislodged during the course of a test.Heat deflection assessment of ABS, using two ofthe six stations available with the 603 HDTM3

Video Capture nowavailable in QMatBy using video capture, you can retrace the test visually, matching features on the test curve to physicalevents associated with the test piece. The more powerful the camera/computer combination, the greaterare the potential applications.The Qmat Video Capture function has beendesigned to only work with constant velocitytests. It can be used with variable velocity tests,but the video playback will not be in sync withthe test curve. This Qmat function is simple touse – just install a USB camera and you are readyto capture a visual record of the test. The videooption is on the tools menu in Qmat Testzone, ifyou wish to video a test, then select ‘VideoRecord’, point the camera at the test piece andclick the TEST SPECIMEN button. If you wishto replay the video, click on the tools menu andclick on ‘Video Replay Test’.The quality of the video capture is limited by thespeed of the computer and is simply a question ofdata rates. The higher the data rate that thecomputer can handle the better the quality ofvideo capture. The quality of the camera alsoplays a role; the better the camera the higherquality the video capture.The video capture specifications can be varied.The resolution of the captured video can beincreased or decreased along with the colourdepth. The frames per second can also beadjusted. If the computer is powerful enough,the Qmat Video Capture can be set up tocompress on the fly. At the end of a 60 secondtest you may have a 500Mb Video file with a‘.AVI’ extension. The file will be saved to a subfolder of the test.In order to make these video files smaller, youcan choose a different compression method tothat of the default. We have found that files canbe reduced to 1/20th the size depending on thecompression option selected.<strong>Tinius</strong> <strong>Olsen</strong>/Hounsfield Ltd.6 Perrywood Business Park, Honeycrock Lane, Salfords, Redhill, Surrey RH1 5DZ, UKTel: +44 (0)1737 765001 Fax: +44 (0)1737 764768 Email: sales@hounsfield.com www.hounsfield.com<strong>Tinius</strong> <strong>Olsen</strong> Inc.Corporate Headquarters,1065 Easton Road, P O Box 1009, Horsham, PA 19044-8009 USATel: (215) 675 7100 Fax: (215)441 0899 Email: info@tiniusolsen.com www.tiniusolsen.comFaxback To the USA on +1 215 441 0899To the UK on +44 (0) 1737 764768Full Name:Job Title:Company:Address:Please send me more information onthe following:Testing...................................(please specify your material or product)Super L testing machinesZip/Post code:Telephone:Email:Please add me to The Standard mailing listCountry:Fax:Please remove me from The Standard mailing listNew Food testersNew heat deflection/Vicat testerVideo capture capabilities in Qmat1332