Improving Temperature Uniformity at –86 °C in a ... - Biomedical

Improving Temperature Uniformity at –86 °C in a ... - Biomedical

Improving Temperature Uniformity at –86 °C in a ... - Biomedical

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

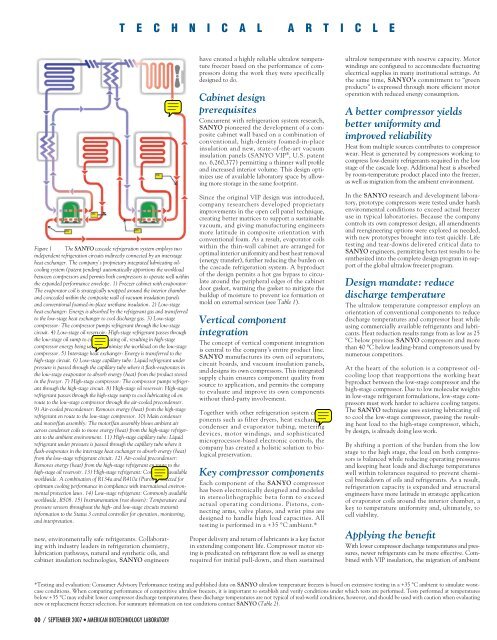

T E C H N I C A L A R T I C L EFigure 1 The SANYO cascade refriger<strong>at</strong>ion system employs two<strong>in</strong>dependent refriger<strong>at</strong>ion circuits <strong>in</strong>directly connected by an <strong>in</strong>terstagehe<strong>at</strong> exchanger. The company’s proprietary <strong>in</strong>tegr<strong>at</strong>ed lubric<strong>at</strong><strong>in</strong>g oilcool<strong>in</strong>gsystem (p<strong>at</strong>ent pend<strong>in</strong>g) autom<strong>at</strong>ically apportions the workloadbetween compressors and permits both compressors to oper<strong>at</strong>e well with<strong>in</strong>the expanded performance envelope. 1) Freezer cab<strong>in</strong>et with evapor<strong>at</strong>or:The evapor<strong>at</strong>or coil is str<strong>at</strong>egically wrapped around the <strong>in</strong>terior chamberand concealed with<strong>in</strong> the composite wall of vacuum <strong>in</strong>sul<strong>at</strong>ion panelsand conventional foamed-<strong>in</strong>-place urethane <strong>in</strong>sul<strong>at</strong>ion. 2) Low-stagehe<strong>at</strong> exchanger: Energy is absorbed by the refrigerant gas and transferredto the low-stage he<strong>at</strong> exchanger to cool discharge gas. 3) Low-stagecompressor: The compressor pumps refrigerant through the low-stagecircuit. 4) Low-stage oil reservoir: High-stage refrigerant passes throughthe low-stage oil sump to cool lubric<strong>at</strong><strong>in</strong>g oil, result<strong>in</strong>g <strong>in</strong> high-stagecompressor energy be<strong>in</strong>g used to m<strong>in</strong>imize the workload on the low-stagecompressor. 5) Interstage he<strong>at</strong> exchanger: Energy is transferred to thehigh-stage circuit. 6) Low-stage capillary tube: Liquid refrigerant underpressure is passed through the capillary tube where it flash-evapor<strong>at</strong>es <strong>in</strong>the low-stage evapor<strong>at</strong>or to absorb energy (he<strong>at</strong>) from the product stored<strong>in</strong> the freezer. 7) High-stage compressor: The compressor pumps refrigerantthrough the high-stage circuit. 8) High-stage oil reservoir: High-stagerefrigerant passes through the high-stage sump to cool lubric<strong>at</strong><strong>in</strong>g oil enroute to the low-stage compressor through the air-cooled precondenser.9) Air-cooled precondenser: Removes energy (he<strong>at</strong>) from the high-stagerefrigerant en route to the low-stage compressor. 10) Ma<strong>in</strong> condenserand motor/fan assembly: The motor/fan assembly blows ambient airacross condenser coils to move energy (he<strong>at</strong>) from the high-stage refrigerantto the ambient environment. 11) High-stage capillary tube: Liquidrefrigerant under pressure is passed through the capillary tube where itflash-evapor<strong>at</strong>es <strong>in</strong> the <strong>in</strong>terstage he<strong>at</strong> exchanger to absorb energy (he<strong>at</strong>)from the low-stage refrigerant circuit. 12) Air-cooled precondenser:Removes energy (he<strong>at</strong>) from the high-stage refrigerant en route to thehigh-stage oil reservoir. 13) High-stage refrigerant: Commonly availableworldwide. A comb<strong>in</strong><strong>at</strong>ion of R134a and R410a (Puron ® ) selected foroptimum cool<strong>in</strong>g performance <strong>in</strong> compliance with <strong>in</strong>tern<strong>at</strong>ional environmentalprotection laws. 14) Low-stage refrigerant: Commonly availableworldwide, R508. 15) Instrument<strong>at</strong>ion (not shown): <strong>Temper<strong>at</strong>ure</strong> andpressure sensors throughout the high- and low-stage circuits transmit<strong>in</strong>form<strong>at</strong>ion to the St<strong>at</strong>us 3 central controller for oper<strong>at</strong>ion, monitor<strong>in</strong>g,and <strong>in</strong>terpret<strong>at</strong>ion.new, environmentally safe refrigerants. Collabor<strong>at</strong><strong>in</strong>gwith <strong>in</strong>dustry leaders <strong>in</strong> refriger<strong>at</strong>ion chemistry,lubric<strong>at</strong>ion p<strong>at</strong>hways, n<strong>at</strong>ural and synthetic oils, andcab<strong>in</strong>et <strong>in</strong>sul<strong>at</strong>ion technologies, SANYO eng<strong>in</strong>eershave cre<strong>at</strong>ed a highly reliable ultralow temper<strong>at</strong>urefreezer based on the performance of compressorsdo<strong>in</strong>g the work they were specificallydesigned to do.Cab<strong>in</strong>et designprerequisitesConcurrent with refriger<strong>at</strong>ion system research,SANYO pioneered the development of a compositecab<strong>in</strong>et wall based on a comb<strong>in</strong><strong>at</strong>ion ofconventional, high-density foamed-<strong>in</strong>-place<strong>in</strong>sul<strong>at</strong>ion and new, st<strong>at</strong>e-of-the-art vacuum<strong>in</strong>sul<strong>at</strong>ion panels (SANYO VIP ® , U.S. p<strong>at</strong>entno. 6,260,377) permitt<strong>in</strong>g a th<strong>in</strong>ner wall profileand <strong>in</strong>creased <strong>in</strong>terior volume. This design optimizesuse of available labor<strong>at</strong>ory space by allow<strong>in</strong>gmore storage <strong>in</strong> the same footpr<strong>in</strong>t.S<strong>in</strong>ce the orig<strong>in</strong>al VIP design was <strong>in</strong>troduced,company researchers developed proprietaryimprovements <strong>in</strong> the open cell panel technique,cre<strong>at</strong><strong>in</strong>g better m<strong>at</strong>rices to support a susta<strong>in</strong>ablevacuum, and giv<strong>in</strong>g manufactur<strong>in</strong>g eng<strong>in</strong>eersmore l<strong>at</strong>itude <strong>in</strong> composite orient<strong>at</strong>ion withconventional foam. As a result, evapor<strong>at</strong>or coilswith<strong>in</strong> the th<strong>in</strong>-wall cab<strong>in</strong>et are arranged foroptimal <strong>in</strong>terior uniformity and best he<strong>at</strong> removal(energy transfer), further reduc<strong>in</strong>g the burden onthe cascade refriger<strong>at</strong>ion system. A byproductof the design permits a hot gas bypass to circul<strong>at</strong>earound the peripheral edges of the cab<strong>in</strong>etdoor gasket, warm<strong>in</strong>g the gasket to mitig<strong>at</strong>e thebuildup of moisture to prevent ice form<strong>at</strong>ion ormold on external services (see Table 1).Vertical component<strong>in</strong>tegr<strong>at</strong>ionThe concept of vertical component <strong>in</strong>tegr<strong>at</strong>ionis central to the company’s entire product l<strong>in</strong>e.SANYO manufactures its own oil separ<strong>at</strong>ors,circuit boards, and vacuum <strong>in</strong>sul<strong>at</strong>ion panels,and designs its own compressors. This <strong>in</strong>tegr<strong>at</strong>edsupply cha<strong>in</strong> ensures component quality fromsource to applic<strong>at</strong>ion, and permits the companyto evalu<strong>at</strong>e and improve its own componentswithout third-party <strong>in</strong>volvement.Together with other refriger<strong>at</strong>ion system componentssuch as filter dryers, he<strong>at</strong> exchanges,condenser and evapor<strong>at</strong>or tub<strong>in</strong>g, meter<strong>in</strong>gdevices, motor w<strong>in</strong>d<strong>in</strong>gs, and sophistic<strong>at</strong>edmicroprocessor-based electronic controls, thecompany has cre<strong>at</strong>ed a holistic solution to biologicalpreserv<strong>at</strong>ion.Key compressor componentsEach component of the SANYO compressorhas been electronically designed and modeled<strong>in</strong> stereolithographic beta form to exceedactual oper<strong>at</strong><strong>in</strong>g conditions. Pistons, connect<strong>in</strong>garms, valve pl<strong>at</strong>es, and wrist p<strong>in</strong>s aredesigned to handle high load capacities. Alltest<strong>in</strong>g is performed <strong>in</strong> a +35 <strong>°C</strong> ambient.*Proper delivery and return of lubricants is a key factor<strong>in</strong> extend<strong>in</strong>g component life. Compressor motor siz<strong>in</strong>gis predic<strong>at</strong>ed on refrigerant flow as well as energyrequired for <strong>in</strong>itial pull-down, and then susta<strong>in</strong>edultralow temper<strong>at</strong>ure with reserve capacity. Motorw<strong>in</strong>d<strong>in</strong>gs are configured to accommod<strong>at</strong>e fluctu<strong>at</strong><strong>in</strong>gelectrical supplies <strong>in</strong> many <strong>in</strong>stitutional sett<strong>in</strong>gs. Atthe same time, SANYO’s commitment to “greenproducts” is expressed through more efficient motoroper<strong>at</strong>ion with reduced energy consumption.A better compressor yieldsbetter uniformity andimproved reliabilityHe<strong>at</strong> from multiple sources contributes to compressorwear. He<strong>at</strong> is gener<strong>at</strong>ed by compressors work<strong>in</strong>g tocompress low-density refrigerants required <strong>in</strong> the lowstage of the cascade loop. Additional he<strong>at</strong> is absorbedby room-temper<strong>at</strong>ure product placed <strong>in</strong>to the freezer,as well as migr<strong>at</strong>ion from the ambient environment.In the SANYO research and development labor<strong>at</strong>ory,prototype compressors were tested under harshenvironmental conditions to exceed actual freezeruse <strong>in</strong> typical labor<strong>at</strong>ories. Because the companycontrols its own compressor design, all amendmentsand reeng<strong>in</strong>eer<strong>in</strong>g options were explored as needed,with new prototypes brought <strong>in</strong>to test quickly. Lifetest<strong>in</strong>g and tear-downs delivered critical d<strong>at</strong>a toSANYO eng<strong>in</strong>eers, permitt<strong>in</strong>g beta test results to besynthesized <strong>in</strong>to the complete design program <strong>in</strong> supportof the global ultralow freezer program.Design mand<strong>at</strong>e: reducedischarge temper<strong>at</strong>ureThe ultralow temper<strong>at</strong>ure compressor employs anorient<strong>at</strong>ion of conventional components to reducedischarge temper<strong>at</strong>ures and compressor he<strong>at</strong> whileus<strong>in</strong>g commercially available refrigerants and lubricants.He<strong>at</strong> reduction results range from as low as 25<strong>°C</strong> below previous SANYO compressors and morethan 40 <strong>°C</strong> below lead<strong>in</strong>g-brand compressors used bynumerous competitors.At the heart of the solution is a compressor oilcool<strong>in</strong>gloop th<strong>at</strong> reapportions the work<strong>in</strong>g he<strong>at</strong>byproduct between the low-stage compressor and thehigh-stage compressor. Due to low molecular weights<strong>in</strong> low-stage refrigerant formul<strong>at</strong>ions, low-stage compressorsmust work harder to achieve cool<strong>in</strong>g targets.The SANYO technique uses exist<strong>in</strong>g lubric<strong>at</strong><strong>in</strong>g oilto cool the low-stage compressor, pass<strong>in</strong>g the result<strong>in</strong>ghe<strong>at</strong> load to the high-stage compressor, which,by design, is already do<strong>in</strong>g less work.By shift<strong>in</strong>g a portion of the burden from the lowstage to the high stage, the load on both compressorsis balanced while reduc<strong>in</strong>g oper<strong>at</strong><strong>in</strong>g pressuresand keep<strong>in</strong>g he<strong>at</strong> loads and discharge temper<strong>at</strong>ureswell with<strong>in</strong> tolerances required to prevent chemicalbreakdown of oils and refrigerants. As a result,refriger<strong>at</strong>ion capacity is expanded and structuraleng<strong>in</strong>eers have more l<strong>at</strong>itude <strong>in</strong> str<strong>at</strong>egic applic<strong>at</strong>ionof evapor<strong>at</strong>or coils around the <strong>in</strong>terior chamber, akey to temper<strong>at</strong>ure uniformity and, ultim<strong>at</strong>ely, tocell viability.Apply<strong>in</strong>g the benefitWith lower compressor discharge temper<strong>at</strong>ures and pressures,newer refrigerants can be more effective. Comb<strong>in</strong>edwith VIP <strong>in</strong>sul<strong>at</strong>ion, the migr<strong>at</strong>ion of ambient*Test<strong>in</strong>g and evalu<strong>at</strong>ion: Consumer Advisory Performance test<strong>in</strong>g and published d<strong>at</strong>a on SANYO ultralow temper<strong>at</strong>ure freezers is based on extensive test<strong>in</strong>g <strong>in</strong> a +35 <strong>°C</strong> ambient to simul<strong>at</strong>e worstcaseconditions. When compar<strong>in</strong>g performance of competitive ultralow freezers, it is important to establish and verify conditions under which tests are performed. Tests performed <strong>at</strong> temper<strong>at</strong>uresbelow +35 <strong>°C</strong> may exhibit lower compressor discharge temper<strong>at</strong>ures; these discharge temper<strong>at</strong>ures are not typical of real-world conditions, however, and should be used with caution when evalu<strong>at</strong><strong>in</strong>gnew or replacement freezer selection. For summary <strong>in</strong>form<strong>at</strong>ion on test conditions contact SANYO (Table 2).00 / SEPTEMBER 2007 • AMERICAN BIOTECHNOLOGY LABORATORY