P-F FLUSH SELF CLINCHING NUTS - HW Eckhardt

P-F FLUSH SELF CLINCHING NUTS - HW Eckhardt

P-F FLUSH SELF CLINCHING NUTS - HW Eckhardt

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

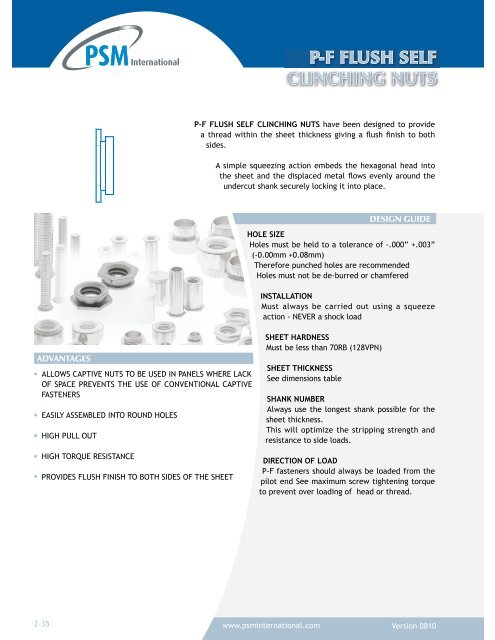

P-F <strong>FLUSH</strong> <strong>SELF</strong><strong>CLINCHING</strong> <strong>NUTS</strong>P-F <strong>FLUSH</strong> <strong>SELF</strong> <strong>CLINCHING</strong> <strong>NUTS</strong> have been designed to providesides.A simple squeezing action embeds the hexagonal head intoundercut shank securely locking it into place.DESIGN GUIDEHOLE SIZEHoles must be held to a tolerance of -.000” +.003”(-0.00mm +0.08mm)Therefore punched holes are recommendedHoles must not be de-burred or chamferedINSTALLATIONMust always be carried out using a squeezeaction - NEVER a shock loadADVANTAGESALLOWS CAPTIVE <strong>NUTS</strong> TO BE USED IN PANELS WHERE LACKOF SPACE PREVENTS THE USE OF CONVENTIONAL CAPTIVEFASTENERSEASILY ASSEMBLED INTO ROUND HOLESHIGH PULL OUTHIGH TORQUE RESISTANCEPROVIDES <strong>FLUSH</strong> FINISH TO BOTH SIDES OF THE SHEETSHEET HARDNESSMust be less than 70RB (128VPN)SHEET THICKNESSSee dimensions tableSHANK NUMBERAlways use the longest shank possible for thesheet thickness.This will optimize the stripping strength andresistance to side loads.DIRECTION OF LOADP-F fasteners should always be loaded from thepilot end See maximum screw tightening torqueto prevent over loading of head or thread.2-35www.psminternational.comVersion 0810

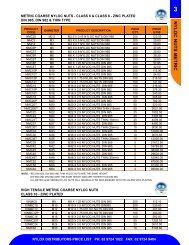

P-F <strong>FLUSH</strong> <strong>SELF</strong><strong>CLINCHING</strong> <strong>NUTS</strong>TECHNICAL DATAMATERIAL CODESP-F - Stainless SteelP-F TYPE (METRIC)CMAXIMUM SHEET HARDNESSP-F = Rb 70AHMETRICTHREADSIZE / CODEM2M2.5M3M4M5M6ShankCodeFor MinSheetThicknessA (max)1 1.50 - 2.3 1.502 2.301 1.50 - 2.3 1.502 2.301 1.50 - 2.3 1.502 2.301 1.50 - 2.3 1.502 2.301 1.50 - 2.3 1.502 2.303 3.1 - 3.85 3.054 3.9 - 4.63 3.845 4.63Hole Size inSheet+0.08 -0.00Diameterof ShankC (max)All dimensions in millimetersHA/FNominalMinimumdistancecentre line holeto sheet edge4.37 4.35 4.80 6.04.37 4.35 4.80 6.04.37 4.35 4.80 6.07.37 7.35 7.90 7.27.92 7.90 8.70 8.08.74 8.72 9.50 8.8HOW TO SPECIFYP-F (Stainless Steel Standard Sizes)Product CodeThread CodeShank CodeP-F-M4-1P-F-M4-1P-F-M4-1Version 0810www.psminternational.com2-36

P-F <strong>FLUSH</strong> <strong>SELF</strong><strong>CLINCHING</strong> <strong>NUTS</strong>TECHNICAL DATAMATERIAL CODEP-F - Stainless Steel)P-F TYPE (UNIFIED)CMAXIMUM SHEET HARDNESSP-F = Rb70AHUNIFIEDTHREADSIZE / CODE256440632832032 / 0240420 / 0428ShankCodeFor MinSheetThicknessA (max)1 .060 -.090 .0602 .0901 .060 -.090 .0602 .0901 .060 -.090 .0602 .0901 .060 -.090 .0602 .0901 .060 -.090 .0602 .0903 .125 -.155 .1204 .156 -.186 .1515 .182Hole Size inSheet+.003 -.000Diameterof ShankC (max)HA/FNominalAll dimensions in inchesMinimum distancecentre line holeto sheet edge.172 .171 .188 .230.172 .171 .188 .230.213 .212 .250 .270.290 .289 .312 .280.312 .311 .343 .310.344 .343 .375 .340HOW TO SPECIFYP-F (Stainless Steel Standard Sizes)Product CodeThread CodeShank CodeP-F-832-1P-F-832-1P-F-832-12-37www.psminternational.com Version 0810

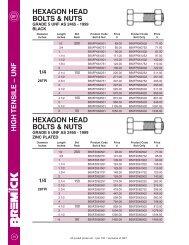

P-F <strong>FLUSH</strong> <strong>SELF</strong><strong>CLINCHING</strong> <strong>NUTS</strong>1.2.3.METHOD OF ASSEMBLYPunch a hole in the metal sheet to the sizerecommended in our technical data table. Deburringof the hole is not recommended.Insert the shank of the fastener into the hole.Apply squeezing pressure sufficient to embedPERFORMANCE DATA (METRIC)ThreadCodeM2M2.5M3M3.5M4M5M6ThreadCodeShankCode121212121212345ShankCodeMax.TighteningTorque forMating Screw(Nm)PERFORMANCE DATA (UNIFIED)256440632832032 / 0240420 / 0428Version 08101212121212345P-F <strong>SELF</strong> <strong>CLINCHING</strong> <strong>NUTS</strong> are easy to install because no specialtooling is necessary. However, it is very important to note they mustalways be installed by a squeeze action press rather than a hammerblow.Punched holes are always recommended.Installation(kN)Test Sheet MaterialCold Rolled Steel5052-H34 AluminumPushout(N)Installation(kN)Pushout(N)0.20 15 1000 10 8500.25 15 1000 10 8500.35 15 1000 10 8500.40 17 1200 12 10000.60 19 1450 13 12001.00 20 1600 14 13003.90 22 2800 17 2000Max.TighteningTorque forMating Screw(in/lbs)Installation(lbs)Cold Rolled SteelTest Sheet MaterialPushout(lbs)5052-H34 AluminumInstallation(lbs)Pushout(lbs)1.8 3300 220 2200 1903.0 3300 200 2200 1903.7 3800 270 2400 2205.5 4200 325 2600 2708.0 4500 360 2800 29040 4900 630 3500 450Note: The above values are averages when correct installation isperformed. Variations in holes size, material and installation will affectyour PSM Technology Centre.www.psminternational.com2-38