The use of FRP in the strengthening of timber-reinforced masonry ...

The use of FRP in the strengthening of timber-reinforced masonry ...

The use of FRP in the strengthening of timber-reinforced masonry ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

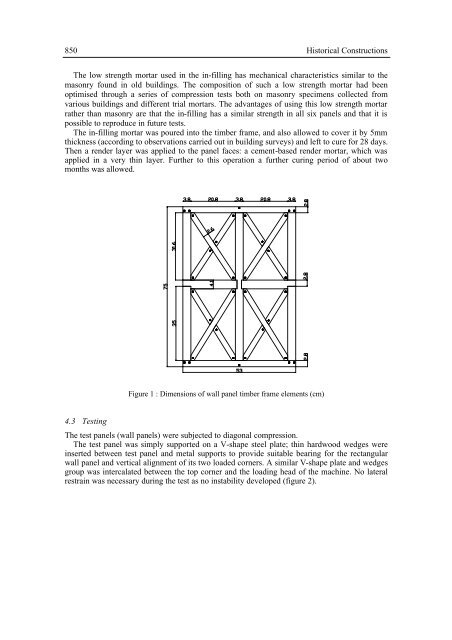

850 Historical Constructions<strong>The</strong> low strength mortar <strong>use</strong>d <strong>in</strong> <strong>the</strong> <strong>in</strong>-fill<strong>in</strong>g has mechanical characteristics similar to <strong>the</strong><strong>masonry</strong> found <strong>in</strong> old build<strong>in</strong>gs. <strong>The</strong> composition <strong>of</strong> such a low strength mortar had beenoptimised through a series <strong>of</strong> compression tests both on <strong>masonry</strong> specimens collected fromvarious build<strong>in</strong>gs and different trial mortars. <strong>The</strong> advantages <strong>of</strong> us<strong>in</strong>g this low strength mortarra<strong>the</strong>r than <strong>masonry</strong> are that <strong>the</strong> <strong>in</strong>-fill<strong>in</strong>g has a similar strength <strong>in</strong> all six panels and that it ispossible to reproduce <strong>in</strong> future tests.<strong>The</strong> <strong>in</strong>-fill<strong>in</strong>g mortar was poured <strong>in</strong>to <strong>the</strong> <strong>timber</strong> frame, and also allowed to cover it by 5mmthickness (accord<strong>in</strong>g to observations carried out <strong>in</strong> build<strong>in</strong>g surveys) and left to cure for 28 days.<strong>The</strong>n a render layer was applied to <strong>the</strong> panel faces: a cement-based render mortar, which wasapplied <strong>in</strong> a very th<strong>in</strong> layer. Fur<strong>the</strong>r to this operation a fur<strong>the</strong>r cur<strong>in</strong>g period <strong>of</strong> about twomonths was allowed.Figure 1 : Dimensions <strong>of</strong> wall panel <strong>timber</strong> frame elements (cm)4.3 Test<strong>in</strong>g<strong>The</strong> test panels (wall panels) were subjected to diagonal compression.<strong>The</strong> test panel was simply supported on a V-shape steel plate; th<strong>in</strong> hardwood wedges were<strong>in</strong>serted between test panel and metal supports to provide suitable bear<strong>in</strong>g for <strong>the</strong> rectangularwall panel and vertical alignment <strong>of</strong> its two loaded corners. A similar V-shape plate and wedgesgroup was <strong>in</strong>tercalated between <strong>the</strong> top corner and <strong>the</strong> load<strong>in</strong>g head <strong>of</strong> <strong>the</strong> mach<strong>in</strong>e. No lateralrestra<strong>in</strong> was necessary dur<strong>in</strong>g <strong>the</strong> test as no <strong>in</strong>stability developed (figure 2).