SECTION 7: Septic Tanks - Onsite Sewage Treatment Program ...

SECTION 7: Septic Tanks - Onsite Sewage Treatment Program ...

SECTION 7: Septic Tanks - Onsite Sewage Treatment Program ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

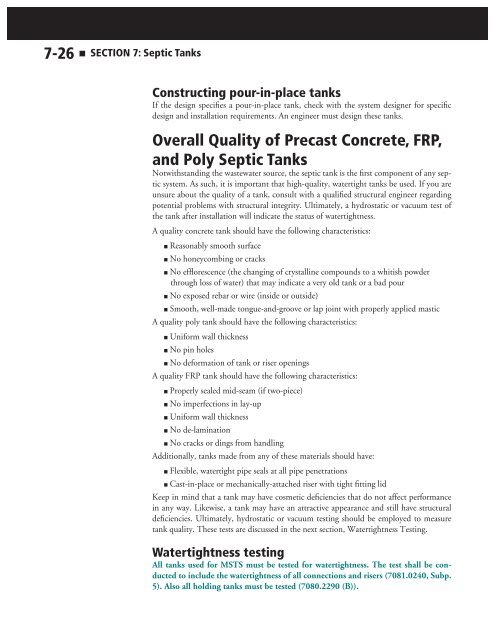

7-26 <strong>SECTION</strong> 7: <strong>Septic</strong> <strong>Tanks</strong>Constructing pour-in-place tanksIf the design specifies a pour-in-place tank, check with the system designer for specificdesign and installation requirements. An engineer must design these tanks.Overall Quality of Precast Concrete, FRP,and Poly <strong>Septic</strong> <strong>Tanks</strong>Notwithstanding the wastewater source, the septic tank is the first component of any septicsystem. As such, it is important that high-quality, watertight tanks be used. If you areunsure about the quality of a tank, consult with a qualified structural engineer regardingpotential problems with structural integrity. Ultimately, a hydrostatic or vacuum test ofthe tank after installation will indicate the status of watertightness.A quality concrete tank should have the following characteristics: Reasonably smooth surface No honeycombing or cracks No efflorescence (the changing of crystalline compounds to a whitish powderthrough loss of water) that may indicate a very old tank or a bad pour No exposed rebar or wire (inside or outside) Smooth, well-made tongue-and-groove or lap joint with properly applied masticA quality poly tank should have the following characteristics: Uniform wall thickness No pin holes No deformation of tank or riser openingsA quality FRP tank should have the following characteristics: Properly sealed mid-seam (if two-piece) No imperfections in lay-up Uniform wall thickness No de-lamination No cracks or dings from handlingAdditionally, tanks made from any of these materials should have: Flexible, watertight pipe seals at all pipe penetrations Cast-in-place or mechanically-attached riser with tight fitting lidKeep in mind that a tank may have cosmetic deficiencies that do not affect performancein any way. Likewise, a tank may have an attractive appearance and still have structuraldeficiencies. Ultimately, hydrostatic or vacuum testing should be employed to measuretank quality. These tests are discussed in the next section, Watertightness Testing.Watertightness testingAll tanks used for MSTS must be tested for watertightness. The test shall be conductedto include the watertightness of all connections and risers (7081.0240, Subp.5). Also all holding tanks must be tested (7080.2290 (B)).