AvBook Intro/notes A/W Sect1 - Shell

AvBook Intro/notes A/W Sect1 - Shell

AvBook Intro/notes A/W Sect1 - Shell

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

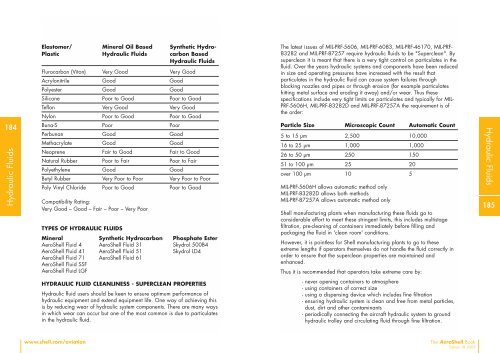

Elastomer/ Mineral Oil Based Synthetic Hydro-Plastic Hydraulic Fluids carbon BasedHydraulic FluidsFlurocarbon (Viton) Very Good Very GoodAcrylonitrile Good GoodPolyester Good GoodSilicone Poor to Good Poor to GoodTeflon Very Good Very GoodNylon Poor to Good Poor to GoodThe latest issues of MIL-PRF-5606, MIL-PRF-6083, MIL-PRF-46170, MIL-PRF-83282 and MIL-PRF-87257 require hydraulic fluids to be "Superclean". Bysuperclean it is meant that there is a very tight control on particulates in thefluid. Over the years hydraulic systems and components have been reducedin size and operating pressures have increased with the result thatparticulates in the hydraulic fluid can cause system failures throughblocking nozzles and pipes or through erosion (for example particulateshitting metal surface and eroding it away) and/or wear. Thus thesespecifications include very tight limits on particulates and typically for MIL-PRF-5606H, MIL-PRF-83282D and MIL-PRF-87257A the requirement is ofthe order:184Hydraulic FluidsBuna-S Poor PoorPerbunan Good GoodMethacrylate Good GoodNeoprene Fair to Good Fair to GoodNatural Rubber Poor to Fair Poor to FairPolyethylene Good GoodButyl Rubber Very Poor to Poor Very Poor to PoorPoly Vinyl Chloride Poor to Good Poor to GoodCompatibility Rating:Very Good – Good – Fair – Poor – Very PoorTYPES OF HYDRAULIC FLUIDSMineral Synthetic Hydrocarbon Phosphate EsterAero<strong>Shell</strong> Fluid 4 Aero<strong>Shell</strong> Fluid 31 Skydrol 500B4Aero<strong>Shell</strong> Fluid 41 Aero<strong>Shell</strong> Fluid 51 Skydrol LD4Aero<strong>Shell</strong> Fluid 71 Aero<strong>Shell</strong> Fluid 61Aero<strong>Shell</strong> Fluid SSFAero<strong>Shell</strong> Fluid LGFParticle Size Microscopic Count Automatic Count5 to 15 µm 2,500 10,00016 to 25 µm 1,000 1,00026 to 50 µm 250 15051 to 100 µm 25 20over 100 µm 10 5MIL-PRF-5606H allows automatic method onlyMIL-PRF-83282D allows both methodsMIL-PRF-87257A allows automatic method only<strong>Shell</strong> manufacturing plants when manufacturing these fluids go toconsiderable effort to meet these stringent limits, this includes multistagefiltration, pre-cleaning of containers immediately before filling andpackaging the fluid in 'clean room' conditions.However, it is pointless for <strong>Shell</strong> manufacturing plants to go to theseextreme lengths if operators themselves do not handle the fluid correctly inorder to ensure that the superclean properties are maintained andenhanced.Thus it is recommended that operators take extreme care by:- never opening containers to atmosphere- using containers of correct size- using a dispensing device which includes fine filtration- ensuring hydraulic system is clean and free from metal particles,dust, dirt and other contaminants- periodically connecting the aircraft hydraulic system to groundhydraulic trolley and circulating fluid through fine filtration.Hydraulic Fluids185HYDRAULIC FLUID CLEANLINESS - SUPERCLEAN PROPERTIESHydraulic fluid users should be keen to ensure optimum performance ofhydraulic equipment and extend equipment life. One way of achieving thisis by reducing wear of hydraulic system components. There are many waysin which wear can occur but one of the most common is due to particulatesin the hydraulic fluid.www.shell.com/aviationThe Aero<strong>Shell</strong> BookEdition 18 2003