Redefining Antifouling Coatings - PaintSquare

Redefining Antifouling Coatings - PaintSquare

Redefining Antifouling Coatings - PaintSquare

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

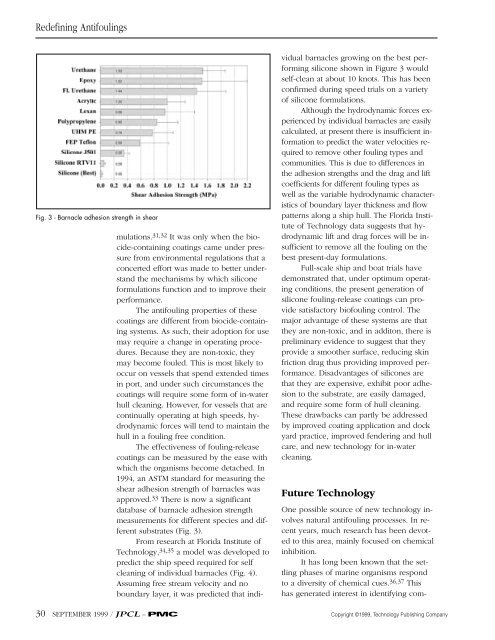

<strong>Redefining</strong> <strong>Antifouling</strong>sFig. 3 - Barnacle adhesion strength in shearmulations. 31,32 It was only when the biocide-containingcoatings came under pressurefrom environmental regulations that aconcerted effort was made to better understandthe mechanisms by which siliconeformulations function and to improve theirperformance.The antifouling properties of thesecoatings are different from biocide-containingsystems. As such, their adoption for usemay require a change in operating procedures.Because they are non-toxic, theymay become fouled. This is most likely tooccur on vessels that spend extended timesin port, and under such circumstances thecoatings will require some form of in-waterhull cleaning. However, for vessels that arecontinually operating at high speeds, hydrodynamicforces will tend to maintain thehull in a fouling free condition.The effectiveness of fouling-releasecoatings can be measured by the ease withwhich the organisms become detached. In1994, an ASTM standard for measuring theshear adhesion strength of barnacles wasapproved. 33 There is now a significantdatabase of barnacle adhesion strengthmeasurements for different species and differentsubstrates (Fig. 3).From research at Florida Institute ofTechnology, 34,35 a model was developed topredict the ship speed required for selfcleaning of individual barnacles (Fig. 4).Assuming free stream velocity and noboundary layer, it was predicted that individualbarnacles growing on the best performingsilicone shown in Figure 3 wouldself-clean at about 10 knots. This has beenconfirmed during speed trials on a varietyof silicone formulations.Although the hydrodynamic forces experiencedby individual barnacles are easilycalculated, at present there is insufficient informationto predict the water velocities requiredto remove other fouling types andcommunities. This is due to differences inthe adhesion strengths and the drag and liftcoefficients for different fouling types aswell as the variable hydrodynamic characteristicsof boundary layer thickness and flowpatterns along a ship hull. The Florida Instituteof Technology data suggests that hydrodynamiclift and drag forces will be insufficientto remove all the fouling on thebest present-day formulations.Full-scale ship and boat trials havedemonstrated that, under optimum operatingconditions, the present generation ofsilicone fouling-release coatings can providesatisfactory biofouling control. Themajor advantage of these systems are thatthey are non-toxic, and in additon, there ispreliminary evidence to suggest that theyprovide a smoother surface, reducing skinfriction drag thus providing improved performance.Disadvantages of silicones arethat they are expensive, exhibit poor adhesionto the substrate, are easily damaged,and require some form of hull cleaning.These drawbacks can partly be addressedby improved coating application and dockyard practice, improved fendering and hullcare, and new technology for in-watercleaning.Future TechnologyOne possible source of new technology involvesnatural antifouling processes. In recentyears, much research has been devotedto this area, mainly focused on chemicalinhibition.It has long been known that the settlingphases of marine organisms respondto a diversity of chemical cues. 36,37 Thishas generated interest in identifying com-30 SEPTEMBER 1999 / JPCL – PMCCopyright ©1999, Technology Publishing Company