DETERMINATION OF THIN FILM'S MECHANICAL PROPERTIES

DETERMINATION OF THIN FILM'S MECHANICAL PROPERTIES

DETERMINATION OF THIN FILM'S MECHANICAL PROPERTIES

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

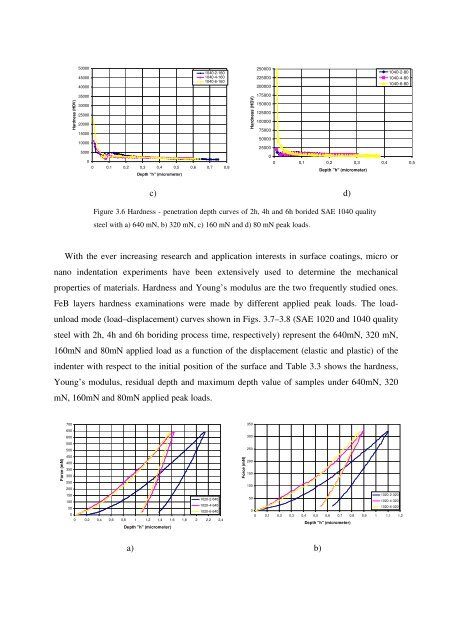

5000045000400001040-2-1601040-4-1601040-6-1602500002250002000001040-2-801040-4-801040-6-80Hardness (HDV)350003000025000200001500010000500000 0,1 0,2 0,3 0,4 0,5 0,6 0,7 0,8Depth "h" (micrometer)Hardness (HDV)17500015000012500010000075000500002500000 0,1 0,2 0,3 0,4 0,5Depth "h" (micrometer)c) d)Figure 3.6 Hardness - penetration depth curves of 2h, 4h and 6h borided SAE 1040 qualitysteel with a) 640 mN, b) 320 mN, c) 160 mN and d) 80 mN peak loads.With the ever increasing research and application interests in surface coatings, micro ornano indentation experiments have been extensively used to determine the mechanicalproperties of materials. Hardness and Young’s modulus are the two frequently studied ones.FeB layers hardness examinations were made by different applied peak loads. The loadunloadmode (load–displacement) curves shown in Figs. 3.7–3.8 (SAE 1020 and 1040 qualitysteel with 2h, 4h and 6h boriding process time, respectively) represent the 640mN, 320 mN,160mN and 80mN applied load as a function of the displacement (elastic and plastic) of theindenter with respect to the initial position of the surface and Table 3.3 shows the hardness,Young’s modulus, residual depth and maximum depth value of samples under 640mN, 320mN, 160mN and 80mN applied peak loads.Force (mN)7003506506003005505002504504002003501503002501002001501020-2-3201001020-2-640501020-4-320501020-4-6401020-6-3201020-6-640 000 0,1 0,2 0,3 0,4 0,5 0,6 0,7 0,8 0,9 1 1,1 1,20 0,2 0,4 0,6 0,8 1 1,2 1,4 1,6 1,8 2 2,2 2,4Depth "h" (micrometer)Depth "h" (micrometer)Force (mN)a) b)