SLEWING RINGS - Rima (UK)

SLEWING RINGS - Rima (UK)

SLEWING RINGS - Rima (UK)

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

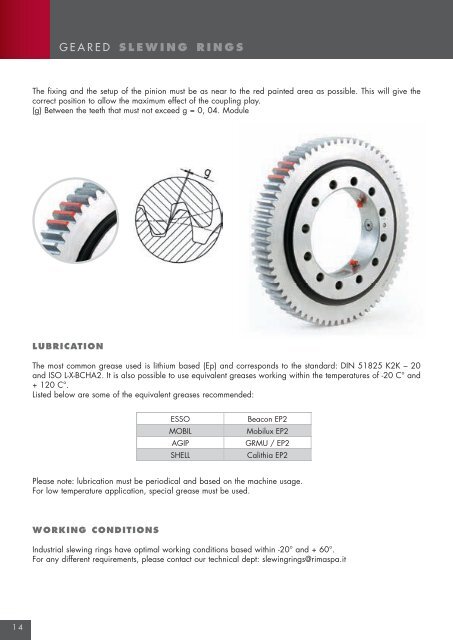

G E A R E D S L E W I N G R I N G SThe fixing and the setup of the pinion must be as near to the red painted area as possible. This will give thecorrect position to allow the maximum effect of the coupling play.(g) Between the teeth that must not exceed g = 0, 04. ModuleLUBRICATIONThe most common grease used is lithium based (Ep) and corresponds to the standard: DIN 51825 K2K – 20and ISO L-X-BCHA2. It is also possible to use equivalent greases working within the temperatures of -20 C° and+ 120 C°.Listed below are some of the equivalent greases recommended:ESSOMOBILAGIPSHELLBeacon EP2Mobilux EP2GRMU / EP2Calithia EP2Please note: lubrication must be periodical and based on the machine usage.For low temperature application, special grease must be used.WORKING CONDITIONSIndustrial slewing rings have optimal working conditions based within -20° and + 60°.For any different requirements, please contact our technical dept: slewingrings@rimaspa.it1 4