Motorcycle safety barrier trials in South Australia: Case study

Motorcycle safety barrier trials in South Australia: Case study

Motorcycle safety barrier trials in South Australia: Case study

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

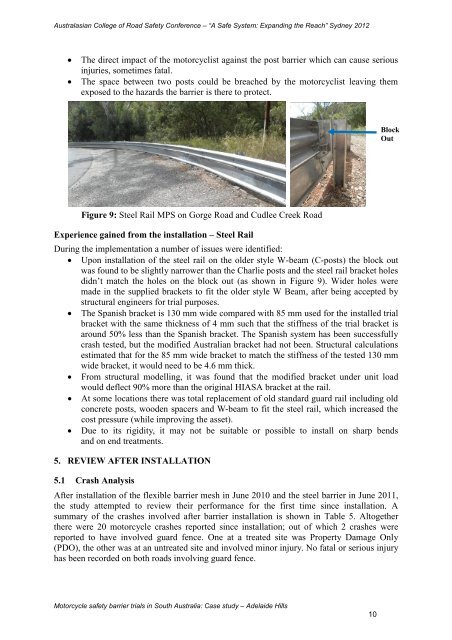

Australasian College of Road Safety Conference – “A Safe System: Expand<strong>in</strong>g the Reach” Sydney 2012The direct impact of the motorcyclist aga<strong>in</strong>st the post <strong>barrier</strong> which can cause serious<strong>in</strong>juries, sometimes fatal.The space between two posts could be breached by the motorcyclist leav<strong>in</strong>g themexposed to the hazards the <strong>barrier</strong> is there to protect.BlockOutFigure 9: Steel Rail MPS on Gorge Road and Cudlee Creek RoadExperience ga<strong>in</strong>ed from the <strong>in</strong>stallation – Steel RailDur<strong>in</strong>g the implementation a number of issues were identified: Upon <strong>in</strong>stallation of the steel rail on the older style W-beam (C-posts) the block outwas found to be slightly narrower than the Charlie posts and the steel rail bracket holesdidn’t match the holes on the block out (as shown <strong>in</strong> Figure 9). Wider holes weremade <strong>in</strong> the supplied brackets to fit the older style W Beam, after be<strong>in</strong>g accepted bystructural eng<strong>in</strong>eers for trial purposes. The Spanish bracket is 130 mm wide compared with 85 mm used for the <strong>in</strong>stalled trialbracket with the same thickness of 4 mm such that the stiffness of the trial bracket isaround 50% less than the Spanish bracket. The Spanish system has been successfullycrash tested, but the modified <strong>Australia</strong>n bracket had not been. Structural calculationsestimated that for the 85 mm wide bracket to match the stiffness of the tested 130 mmwide bracket, it would need to be 4.6 mm thick. From structural modell<strong>in</strong>g, it was found that the modified bracket under unit loadwould deflect 90% more than the orig<strong>in</strong>al HIASA bracket at the rail. At some locations there was total replacement of old standard guard rail <strong>in</strong>clud<strong>in</strong>g oldconcrete posts, wooden spacers and W-beam to fit the steel rail, which <strong>in</strong>creased thecost pressure (while improv<strong>in</strong>g the asset). Due to its rigidity, it may not be suitable or possible to <strong>in</strong>stall on sharp bendsand on end treatments.5. REVIEW AFTER INSTALLATION5.1 Crash AnalysisAfter <strong>in</strong>stallation of the flexible <strong>barrier</strong> mesh <strong>in</strong> June 2010 and the steel <strong>barrier</strong> <strong>in</strong> June 2011,the <strong>study</strong> attempted to review their performance for the first time s<strong>in</strong>ce <strong>in</strong>stallation. Asummary of the crashes <strong>in</strong>volved after <strong>barrier</strong> <strong>in</strong>stallation is shown <strong>in</strong> Table 5. Altogetherthere were 20 motorcycle crashes reported s<strong>in</strong>ce <strong>in</strong>stallation; out of which 2 crashes werereported to have <strong>in</strong>volved guard fence. One at a treated site was Property Damage Only(PDO), the other was at an untreated site and <strong>in</strong>volved m<strong>in</strong>or <strong>in</strong>jury. No fatal or serious <strong>in</strong>juryhas been recorded on both roads <strong>in</strong>volv<strong>in</strong>g guard fence.<strong>Motorcycle</strong> <strong>safety</strong> <strong>barrier</strong> <strong>trials</strong> <strong>in</strong> <strong>South</strong> <strong>Australia</strong>: <strong>Case</strong> <strong>study</strong> – Adelaide Hills10