Welding column & booms - Sveiseeksperten

Welding column & booms - Sveiseeksperten

Welding column & booms - Sveiseeksperten

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

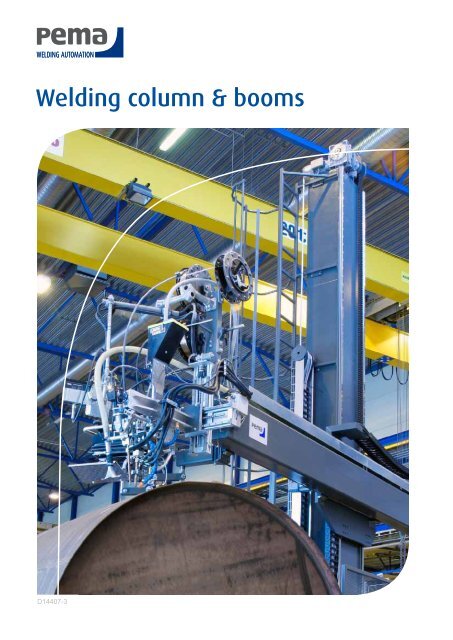

<strong>Welding</strong> <strong>column</strong> & <strong>booms</strong>D14407-3

3High quality, comprehensive supportAll components used in PEMA <strong>column</strong> & <strong>booms</strong> are provided by wellestablished,widely recognised suppliers. Only the best componentsare accepted. This guarantees full performance even under toughestproduction conditions. PEMA’s comprehensive customer support furtherensures continuous, uninterrupted production and optimal utilisation ofequipment.Wide variety of applicationsFocusing first and foremost on the welding processes themselves, allPEMA <strong>column</strong> & <strong>booms</strong> as well as their accessories have been developedin order to compliment the welding process. Combined with e.g.PEMA roller beds, the result is a complete welding solution providingthe required performance which meets or exceeds your productivity demands.By choosing PEMA you are investing in a partner with the rightexperience and the right solutions to help you to boost your productivity.Extra heavy duty PEMA welding stationApplication examples, standard solutions<strong>Welding</strong> of longitudinal seams of shellsor beams. Both internal and externalwelding is possible.<strong>Welding</strong> of circumferential seam. Alsowelding of flanges is possible in this application.Outside welding of circumferential seam.The work piece is rotatated by PEMAroller beds.Application examples, engineering solutionsExternal and internal welding of two ormore circumferential seams simultaneouslyby using several welding torches.Simultaneous welding of several longitudinalseams in beams. In this case, the<strong>column</strong> & boom is driven on rails. Automaticseam tracking is recommended.Tilting and turning movement of a PEMApositioner can be interfaced to a colum &boom, e.g. in case of automatic weldingof demanding dish ends or similar workpieces.

4Medium Duty seriesPEMA MD is a medium-duty <strong>column</strong> & boom series for welding hard automation purposes. A stable constructionwith rack-bar drive and linear rail movements, PEMA MD provides smooth operation resulting inexcellent welding quality. It is a versatile and cost-effective solution especially for single wire and twinSAW welding, but suits well also for MIG/MAG and TIG welding processes.• Cost-effective way to improveproductivity, weldingquality and safety• Ideal equipment for everyhard automation solution• Several dimensions, weldingprocesses, and• Wide range of accessoriesto choose from• Technologically advancedPEMA MD 4x4 <strong>column</strong> & boom with set of PEMA roller beds.Internal longitudinal welding with PEMA <strong>column</strong> & boomand a set of roller bedsPEMA <strong>column</strong> & boom with a positioner

5Ideal hard automation solutionPEMA MD series <strong>column</strong> & <strong>booms</strong> weld both longitudinal andcircumferential seams. The MD series sizes range from 3 x 3 metersup to 5 x 5 meters (<strong>column</strong> movement x boom movement).The MD can easily be combined with PEMA roller beds andpositioners to improve productivity, welding quality and safetyat work. Safety is ensured with e.g. a falling prevention device.Also available with integrated control system which combineswelding parameter control, welding data storage, remote controland other advanced welding functions into the <strong>column</strong> & boomcontrol interface. Can be equipped with motorised rail cars and amultitude of other accessories: see page 12 for modulation andaccessory list.Versatile mounting of welding equipmentThe standard PEMA MD series <strong>column</strong> & boom can be used for weldinglongitudinal and circumferential seams. This makes the use of a PEMA<strong>column</strong> & boom and PEMA roller beds on the same rails possible.Outside or inside welding of alongitudinal seamOutside or inside welding of acircumferential seamB1000DA90017501800Medium Duty Column & BoomsMD-SERIES: 3 x 3 MD 4 x 4 MD 5 x 5 MDVertical reach [A] 1000 – 4000 mm 1000 – 5000 mm 1000 – 6000 mmFR1400Boom reach from c-c [B] 900 – 3900 mm 900 – 4900 mm 900 – 5900 mmColumn rotation speed 360 degrees / 2 min 360 degrees / 2 min 360 degrees / 2 minRail car speed 2500 mm/min 2500 mm/min 2500 mm/minRail track span; inside-inside 1750 mm 1750 mm 1750 mmTotal height [D] 5050 mm 6050 mm 7050 mm

6Heavy Duty seriesPEMA HD is a heavy-duty <strong>column</strong> & boom series for demanding welding automation purposes. With rollerbed and positioner interface as a standard feature, it is the right solution especially for tandem SAW weldingin complete welding hard automation cells, but suits well also for single wire and twin SAW as well asTIG and MIG/MAG welding processes.• Easy to integrate with PEMA positionersand roller beds• Motorised movements of the<strong>column</strong>, boom and on rails• Operator’s seat as optionPEMA 6x6 HD <strong>column</strong> & boom integrated to a PEMA positionerPEMA HD <strong>column</strong> & boomEU type certificated operator seat is available as option

7Heavy hard automation capacityPEMA HD series sizes range from 4 x 4 meters up to 7 x 7 meters(<strong>column</strong> movement x boom movement). PEMA roller beds andpositioners are easy to integrate to PEMA HD <strong>column</strong> & <strong>booms</strong>.With this kind of combinations, automated welding of workpieces can be carried out reliably and to highest standards ofproductivity and welding quality. The HD series <strong>column</strong> & <strong>booms</strong>weld both longitudinal and circumferential seams: the <strong>column</strong>,boom and rail movements are all motorised. In addition to <strong>column</strong>and boom movements, welding is also possible with boommovement and, as an option, with movement on rails. See page12 for modulation and accessory list.Every PEMA HD series <strong>column</strong> & boom is built on the same principlesas PEMA´s high-end engineering solutions. Designed andmanufactured in PEMA´s own factory in Finland, each machineis carefully tested before delivery. This stands for easy and quickinstallation as well as efficient commissioning.BDA13601250115023502410Heavy Duty Column & BoomsHD-SERIES: 4 x 4 HD 5 x 5 HD 6 x 6 HD 7 x 7 HD 8 x 6 HDVertical reach [A] 1150 – 5150 mm 1150 – 6150 mm 1150 – 7150 mm 1150 – 8150 mm 1150 – 9150 mmBoom reach from c-c [B] 1250 – 5250 mm 1250 – 6250 mm 1250 – 7250 mm 1250 – 8250 mm 1250 – 7250 mmColumn rotation speed 360 degrees / 2 min 360 degrees / 2 min 360 degrees / 2 min 360 degrees / 2 min 360 degrees / 2 minRail car speed 2500 mm/min 2500 mm/min 2500 mm/min 2500 mm/min 2500 mm/minRail track span; inside-inside 2350 mm 2350 mm 2350 mm 2350 mm 2350 mmFR2000Total height [D] 6300 mm 7300 mm 8300 mm 9300 mm 10300 mm

8Extra Heavy Duty seriesPEMA EHD is an extra heavy-duty <strong>column</strong> & boom series for very demanding welding automation purposes.Always built to fulfil specific customer production requirements, PEMA EHD <strong>column</strong> & <strong>booms</strong> areperfect solutions especially for heavy SAW welding in tailored welding hard automation cells.• Ideal for heavy SAW welding processes• Easy to integrate with PEMA positionersand roller beds• Motorised movements of the <strong>column</strong>,boom and on rails• Operator’s seat as optionPEMA EHD equipped with heavy SAW welding power sources and welding headsPEMA EHD <strong>column</strong> & <strong>booms</strong> are always built to fulfilspecific customer production requirementsPEMA EHD is often used for very demanding weldingapplications

9Extra heavy capacity, ultimate qualityPEMA EHD series sizes range from 7 x 7 meters up to 10 x 10meters (<strong>column</strong> movement x boom movement. PEMA rollerbeds and positioners readily integrated to PEMA EHD <strong>column</strong> &<strong>booms</strong> to form customer-specific, modulated hard automationcells for very heavy steel production. With this kind of combinations,automated welding of work pieces can be carried out reliablyand to highest standards of productivity and welding quality.The EHD series <strong>column</strong> & <strong>booms</strong> weld both longitudinal andcircumferential seams: the <strong>column</strong>, boom and rail movementsare all motorised. In addition to <strong>column</strong> and boom movements,welding is also possible with boom movement and, as an option,with movement on rails. In addition to all SAW processes,strip cladding and different narrow gap applications can be integrated.See page 12 for modulation and accessory list.BAD29943400Extra Heavy Duty Column & BoomsEEHD-SERIES: 7 x 7 EHD 8 x 8 EHD 9x9 EHD 10 x 10 EHDVertical reach [A] 1500-8500 mm 1500-9500 mm 2100 – 11000 mm (TBC) 2100 – 12100 mm (TBC)Boom reach from c-c [B] 1500-8500 mm 1500-9500 mm 2000 – 11000 mm (TBC) 2000 – 12000 mm (TBC)Column rotation speed 360 degrees / 3 min 360 degrees / 3 min 360 degrees / 2 min 360 degrees / 2 minRail car speed 2500 mm/min 2500 mm/min 2500 mm/min 2500 mm/minFRRail track span; inside-inside [E] 3000 3000 TBC TBCTotal height [D] 10000 mm (TBC) 11000mm (TBC) 13600 (TBC) 14600 mm (TBC)

10PEMA <strong>Welding</strong> platformBesides to standard PEMA <strong>column</strong> & boom series, roller beds and positioners, PEMA designs andmanufactures also welding platforms. Typically a part of a larger engineering solution, the platforms areoften delivered together with heavy-duty roller beds or large welding positioners. The movement rangecan be up to 12 x 10 meters.PEMA fin-bar calibrating machine• Very heavy welding applications• Huge production capacity• Typically delivered as the key part ofa larger engineering solution• Turn-key deliveriesCalibrated fin-baris automaticallycut and fed to thepanel linePEMA is able to supply complete project deliveriesOperator controls welding process on a safe workingplatformWMP welding platforms are especially designed for thespecial customer requirements

11Huge welding capacityIn case of welding platforms, the welding processes are usuallySAW with several wires, strip cladding, or narrow gap type solutionswith single or double wire. Also tandem MIG/MAG is available.In special cases, even 4 sets of double tandem SAW maybe mounted to a special double-sided platform: this arrangementenables simultaneous use of 16 wires.Heavy welding applicationsTypical welding platform work pieces are heavy and thickwalledpressure vessels, components for nuclear power plants,offshore constructions, or e.g. wind energy plant towers. PEMAWMP welding platforms are especially designed for this type ofproduction and facilitate the special requirements of the correspondingtasks.Fixed boom with a moving carriageStandard PEMA WMP welding platforms are of <strong>column</strong> & boomtype. The construction is very heavy because the stability ofthe boom is a key issue. The boom is equipped with a movingwelding carriage and a safe working platform for the operator tocontrol the welding process. Standard PEMA welding platformsare equipped with motorised travelling carriage.Flawless qualityThe work pieces have to meet tight welding quality requirements.That’s why a fully automated welding process is a must.Therefore, PEMA WMP welding platforms are usually equippedwith optional fully automatic controls for both the welding processand the movements. PEMA roller beds or PEMA positionerscan be completely integrated to this same control interface.As the world’s leading welding automation supplier, PEMA hasthe resources to supply complete project deliveries from basicstudies to final commissioning, and further customer support forthe all PEMA solutions.<strong>Welding</strong> platformsWMP 8 x 8 R WMP 10 x 8 R WMP 12 x 8 R WMP 12 x 10 RVertical reach 1000 – 9000 mm 1000 – 11000 mm 1000 – 13000 mm 1000 – 13000 mmCarriage reach from c-c 1600 – 9600 mm 1600 – 9600 mm 1600 – 9600 mm 1600 – 11600 mmOperator platform Included Included Included Included

12Modulation and accessoriesLD series MD series HD series EHD seriesColumn2 m ●- vertical stroke3 m ●4 m ● ●5 m ● ●6 m ●7 m ● ●8 m ● ●9 m ●10 m ●Boom2 m ●- horizontal stroke3 m ●4 m ● ●5 m ● ●6 m ●7 m ● 1) ●8 m ●9 m ●10 m ●BaseFloor mounted ● ● ● ●- with rotationRail carriage ● ● ●<strong>Welding</strong> equipment TIG ● ● ●MIG/MAG ● ● ●Single SAW ● ● ● ●Twin SAW ● ● ● ●Tandem SAW ● ●Tandem Twin SAW ● ●Compact Single SAW, min diameter 600 ● ● ●Compact Tandem SAW ● ●Cross slide Manual 100x100, 200x200, 300x300 ● ● ● ●Motorised 200x200, 300x300 ● ● ● ●<strong>Welding</strong> head mounting Longitudinal ● ●Circumferential ● ●Turnable 90° ● ● ● ●Flux handling for SAW Pressured air operated ● ● ● ●Compact vacuum operated ● ● ●Vacuum unit operated ● ● ●Heavy duty vacuum operated ● ●Wire reels Front 30 kg ○ ○ ○Back 30 kg ● ○ ○ ○Back 100kg ○ ○ ○Platform or additional carriage: 250 kg ○ ○ ○Carriage for wire drums, up to 4x1000 kg ○ ○Control Basic User Interface ● ● ●Advanced User Interface ● ● ●Camera ○ ○ ○Seam tracking Optical height control ○ ○ ○ ○Electro-mechanical seam tracking ○ ○ ○ ○Laser seam tracking ○ ○ ○Energy chain Rail movement 4-30m ○ ○ ○Rails ○ ○ ○Operator seat Seat including ladders ○ ○ 2)Roller guides For welding with rail movement ○ ○● = Standard feature○ = Optional accessory1) No operator seat available2) Also operator platform available on request

13Pema <strong>column</strong> & <strong>booms</strong> have a modular construction and can be equipped with various accessories.Depending on the employed welding process, used material and the geometry of manufactured products,every <strong>column</strong> & boom can be modularly tailored to best suit the task at hand.<strong>Welding</strong> equipment and processes<strong>Welding</strong> heads are equipped with all the needed accessories for efficient and high quality welds. This may include ina e.g. Tandem SAW process a 100mm vertical slide in leading torch, a 100mm horizontal slide, a tilt slide for trailingtorch, a spot light, a laser pilot lamp and Lincoln Electric or PEMA high quality torches.TIGTIG (GTAW) is most commonlyused to weld thin sections ofstainless steel and non-ferrousmetals such as aluminum.MIG/MAGMIG (GMAW) is the mostcommon industrial weldingprocess, preferred for itsversatility, speed and relativeease of adapting the process toautomation.Single SAWA versitile process that can beused for a wide range of singlepassand multi-pass applications.In submerged-arc processes,the arc is struck beneatha covering layer of flux.Twin SAWA high-penetration / high-depositionprocess especially suitedfor making high-speed filletwelds and overlap joints.Tandem SAWA high deposition rate processfor filling a joint quicker withfewer passes. Can also be usedto obtain faster weld speeds forsingle-pass applications.Tandem Twin SAWExtremely high deposition ratesare obtainable by using twotwin arcs. The ultimate choice inwelding thicker materials.Compact Single SAW,min diameter 600 mmSpecially designed weldinghead for small diameterworkpieces. Includes flux supplyand suction, electro-mechanicalseam tracking is possible.Compact Tandem SAWSpecially designed Tandemhead. Includes torch adjustmentslides, flux supply and suction.Electro-mechanical seam trackingoption is available.Cross slideStandard Heavy duty cross slides can be used in all welding processes.These can be chosen from 100mm to 300mm stroke both invertical and in horizontal direction. The slides are equipped withpowerful and reliable DC motor that can operated with seam trackingas a servo system. Also manual slides are available. All slidesare equipped with covers with good resistance to welding splatterand hot material.Special slides can be made to customer needs for extra heavy use,long travels or special movements.Standard cross slideSpecial cross slide

14Modulation and accessories<strong>Welding</strong> head fixingControl<strong>Welding</strong> head fixing is selectedaccording to the needed solution.For Tandem process, PEMA can offerspecial head fixing for longitudinal orcircumferencial welding. With turnablewelding head, both arrangementsare possible. All standard Pemasingle SAW and Twin saw heads areequipped with turnable heads.Longitudinal Circumferential Turnable 90°Flux handling for SAW3 3 2 23 3 4 488Different types offlux handing solutionsare selectedaccording to thecustomer needs.3 3 2 211Pressured air operated flux handling3 33 3 6 66 61 1551 15 5113 3 4 48 81 11 1Column & boom Column #2 & boom #2Column & boom Column #3 & boom #3Vacuum unit operated flux handling3 33 3Column & boom Column #2 & boom #2Column & boom Column #3 & boom #3886 61 15 5667 71 15 5Column 7& boom Column #27& boom #2Column & boom Column #3 & boom #388Flux handlingequipment1. Pressure tank(heated/notheated)2. Filter unit3. Recovery unit4. Vacuum andfilter unit5. Heavy dutyvacuum andfilter unit6. Cyclone7. Slag container8. Flux siloCompact vacuum operatedHeavy duty vacuum operatedColumn & boom Column #2 & boom #2Column & boom Column #3 & boom #3Wire reelsCamera1 234Locations1. Boom front: 30 kg reel2. Boom back: 30 or 100 kg reel3. Platform or additional carriage:250 kg reels and additionalwire feeders4. Platform or additional carriage:250 to 500 kg or up to4x 1000 kg AccuTrack ® drumpackages and additional wirefeedersCamera option isrecommended forplatform-operated<strong>column</strong> & <strong>booms</strong>.

15ControlBasic User Interface B• Column & boom movements• Basic welding functions• Basic interface for PEMA positionersand roller bedsMD/HD BOOM ENDMD/HD BOOM ENDAdvanced User Interface A• Column & Bboom movements B• Advanced welding functions• Production data logging• WPS Manager• Service Manager• Advanced interface for PEMA positionersand roller beds• Lincoln Electric ArcLink ® CinterfaceCPEMA offers two different levelsHD/EHD BOOM END, OPERATOR SEATof user interfaces. Operating panelAAlocation can be selected to fulfilthe requirements of each application.HD/EHD BOOM END, OPERATOR SEATCCMD/HD BOOM ENDBoom end operatedMD/HD BOOM ENDPlatform operatedHD/EHD BOOM END, OPERATOR HD/EHD SEAT BOOMMD/HD/EHDEND, OPERATORPLATFORM,SEATMD/HD/EHD BASIC PLATFORM, BASICMD/HD/EHD PLATFORM, MD/HD/EHD ADVANCEDPLATFORM, ADVANCEDBBAADDDDBBAACCCCMD/HD/EHD PLATFORM, BASICDBasic boom end operatedMD/HD/EHD PLATFORM, BASIC(MD/HD-models)B: <strong>Welding</strong> functions, <strong>column</strong>& boom movements, wirefeed & cross slide controlsDC: Column & boom movementsBBAdvanced boom end / seatMD/HD/EHD PLATFORM, ADVANCEDoperated (HD/EHD-models)A: <strong>Welding</strong> functions, <strong>column</strong>& boom movements, wirefeed & cross slide controlsDDC: Column & boom movementsMD/HD/EHD PLATFORM, ADVANCEDABasic platform operated(MD/HD-models)B: <strong>Welding</strong> functions, <strong>column</strong>& boom movementsD: Wire feed & cross slidecontrolsCamera recommendedAAdvanced platform operated(MD/HD/EHD-models)A: <strong>Welding</strong> functions, <strong>column</strong> &boom movementsD: Wire feed & cross slidecontrolsCamera recommendedSeam trackingLasersensorElectromechanicalsensorLaserstripeprojectorCameraDifferent typesof seam trackingsolutionsare selectedaccording tothe customerneeds.Optical height controlElectro-mechanicalLaser tracking with cameraOperator seatEnergy chainRailsEU type certificated operator seat withladders.Energy chain for rail movement.Rails including accessories, rail stoppersand rail movement limits.

PEMA welding automation – Sparking yourbusinessPEMA welding automation comes from Pemamek Oy Ltd, theworld’s leading specialist in designing and manufacturing weldingmechanisation and automation systems, and work-piece handlingequipment. Pemamek uses and produces high technology. Utilisingthe best available robot and automation technology, everyPEMA product and system is uncompromisingly designed to improvecustomer competitiveness and productivity. Established in1970, Pemamek has constantly strived to supply the best weldingautomation solutions in the world.PEMA systems and comprehensive customersupport services are specifically engineeredfor the following industries:• Heavy engineering• Mobile machinery• Civil construction• Shipbuilding and offshore• Industrial boilers• Wind energy• Process and nuclearPEMA products and services are used in more than50 countries around the world.PEMAMEK OY LTDLamminkatu 47, FI-32201 Loimaa, FinlandPhone: +358 2 760 771 Fax: +358 2 762 8660 e-mail: pema@pemamek.comwww.pemamek.com