Stair-nosing profiles.pdf - Northland Construction Supplies

Stair-nosing profiles.pdf - Northland Construction Supplies

Stair-nosing profiles.pdf - Northland Construction Supplies

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

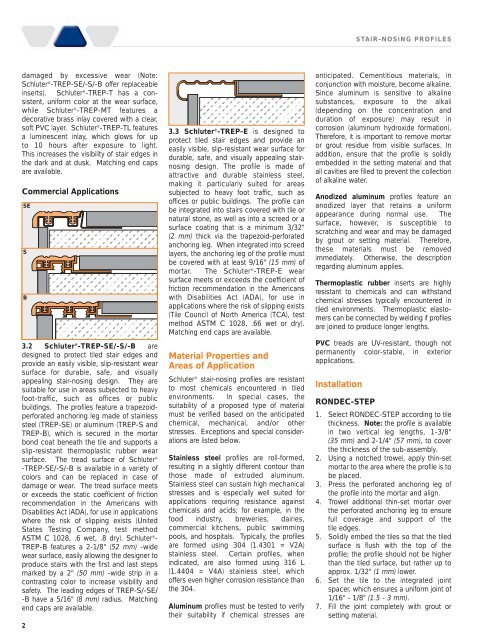

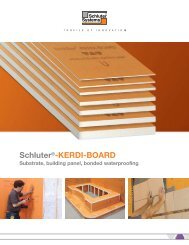

STAIR-NOSING PROFILESdamaged by excessive wear (Note:Schluter ® -TREP-SE/-S/-B offer replaceableinserts). Schluter ® -TREP-T has a consistent,uniform color at the wear surface,while Schluter ® -TREP-MT features adecorative brass inlay covered with a clear,soft PVC layer. Schluter ® -TREP-TL featuresa luminescent inlay, which glows for upto 10 hours after exposure to light.This increases the visibility of stair edges inthe dark and at dusk. Matching end capsare available.Commercial ApplicationsSESB3.2 Schluter ® -TREP-SE/-S/-B aredesigned to protect tiled stair edges andprovide an easily visible, slip-resistant wearsurface for durable, safe, and visuallyappealing stair-<strong>nosing</strong> design. They aresuitable for use in areas subjected to heavyfoot-traffic, such as offices or publicbuildings. The <strong>profiles</strong> feature a trapezoidperforatedanchoring leg made of stainlesssteel (TREP-SE) or aluminum (TREP-S andTREP-B), which is secured in the mortarbond coat beneath the tile and supports aslip-resistant thermoplastic rubber wearsurface. The tread surface of Schluter ®-TREP-SE/-S/-B is available in a variety ofcolors and can be replaced in case ofdamage or wear. The tread surface meetsor exceeds the static coefficient of frictionrecommendation in the Americans withDisabilities Act (ADA), for use in applicationswhere the risk of slipping exists (UnitedStates Testing Company, test methodASTM C 1028, .6 wet, .8 dry). Schluter ® -TREP-B features a 2-1/8" (52 mm) -widewear surface, easily allowing the designer toproduce stairs with the first and last stepsmarked by a 2" (50 mm) -wide strip in acontrasting color to increase visibility andsafety. The leading edges of TREP-S/-SE/-B have a 5/16" (8 mm) radius. Matchingend caps are available.23.3 Schluter ® -TREP-E is designed toprotect tiled stair edges and provide aneasily visible, slip-resistant wear surface fordurable, safe, and visually appealing stair<strong>nosing</strong>design. The profile is made ofattractive and durable stainless steel,making it particularly suited for areassubjected to heavy foot traffic, such asoffices or public buildings. The profile canbe integrated into stairs covered with tile ornatural stone, as well as into a screed or asurface coating that is a minimum 3/32"(2 mm) thick via the trapezoid-perforatedanchoring leg. When integrated into screedlayers, the anchoring leg of the profile mustbe covered with at least 9/16" (15 mm) ofmortar. The Schluter ® -TREP-E wearsurface meets or exceeds the coefficient offriction recommendation in the Americanswith Disabilities Act (ADA), for use inapplications where the risk of slipping exists(Tile Council of North America (TCA), testmethod ASTM C 1028, .66 wet or dry).Matching end caps are available.Material Properties andAreas of ApplicationSchluter ® stair-<strong>nosing</strong> <strong>profiles</strong> are resistantto most chemicals encountered in tiledenvironments. In special cases, thesuitability of a proposed type of materialmust be verified based on the anticipatedchemical, mechanical, and/or otherstresses. Exceptions and special considerationsare listed below.Stainless steel <strong>profiles</strong> are roll-formed,resulting in a slightly different contour thanthose made of extruded aluminum.Stainless steel can sustain high mechanicalstresses and is especially well suited forapplications requiring resistance againstchemicals and acids; for example, in thefood industry, breweries, dairies,commercial kitchens, public swimmingpools, and hospitals. Typically, the <strong>profiles</strong>are formed using 304 (1.4301 = V2A)stainless steel. Certain <strong>profiles</strong>, whenindicated, are also formed using 316 L(1.4404 = V4A) stainless steel, whichoffers even higher corrosion resistance thanthe 304.Aluminum <strong>profiles</strong> must be tested to verifytheir suitability if chemical stresses areanticipated. Cementitious materials, inconjunction with moisture, become alkaline.Since aluminum is sensitive to alkalinesubstances, exposure to the alkali(depending on the concentration andduration of exposure) may result incorrosion (aluminum hydroxide formation).Therefore, it is important to remove mortaror grout residue from visible surfaces. Inaddition, ensure that the profile is solidlyembedded in the setting material and thatall cavities are filled to prevent the collectionof alkaline water.Anodized aluminum <strong>profiles</strong> feature ananodized layer that retains a uniformappearance during normal use. Thesurface, however, is susceptible toscratching and wear and may be damagedby grout or setting material. Therefore,these materials must be removedimmediately. Otherwise, the descriptionregarding aluminum applies.Thermoplastic rubber inserts are highlyresistant to chemicals and can withstandchemical stresses typically encountered intiled environments. Thermoplastic elastomerscan be connected by welding if <strong>profiles</strong>are joined to produce longer lengths.PVC treads are UV-resistant, though notpermanently color-stable, in exteriorapplications.InstallationRONDEC-STEP1. Select RONDEC-STEP according to tilethickness. Note: the profile is availablein two vertical leg lengths, 1-3/8"(35 mm) and 2-1/4" (57 mm), to coverthe thickness of the sub-assembly.2. Using a notched trowel, apply thin-setmortar to the area where the profile is tobe placed.3. Press the perforated anchoring leg ofthe profile into the mortar and align.4. Trowel additional thin-set mortar overthe perforated anchoring leg to ensurefull coverage and support of thetile edges.5. Solidly embed the tiles so that the tiledsurface is flush with the top of theprofile; the profile should not be higherthan the tiled surface, but rather up toapprox. 1/32" (1 mm) lower.6. Set the tile to the integrated jointspacer, which ensures a uniform joint of1/16" - 1/8" (1.5 - 3 mm).7. Fill the joint completely with grout orsetting material.