You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

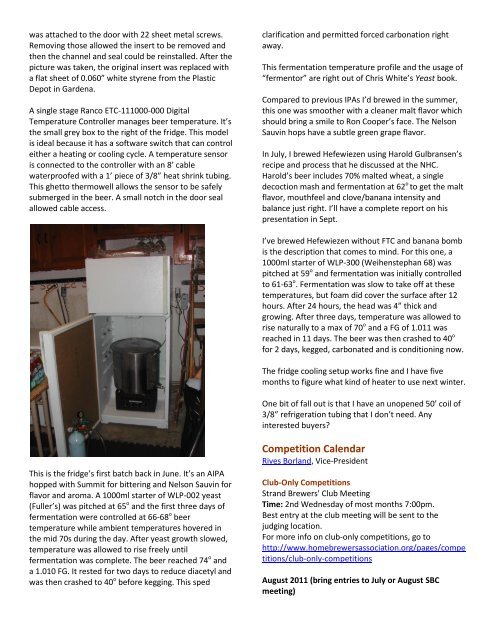

was attached to the door with 22 sheet metal screws.Removing those allowed the insert to be removed andthen the channel and seal could be reinstalled. After thepicture was taken, the original insert was replaced witha flat sheet of 0.060” white styrene from the PlasticDepot in Gardena.A single stage Ranco ETC-111000-000 DigitalTemperature Controller manages beer temperature. It’sthe small grey box to the right of the fridge. This modelis ideal because it has a software switch that can controleither a heating or cooling cycle. A temperature sensoris connected to the controller with an 8’ cablewaterproofed with a 1’ piece of 3/8” heat shrink tubing.This ghetto thermowell allows the sensor to be safelysubmerged in the beer. A small notch in the door sealallowed cable access.clarification and permitted forced carbonation rightaway.This fermentation temperature profile and the usage of“fermentor” are right out of Chris White’s Yeast book.Compared to previous IPAs I’d brewed in the summer,this one was smoother with a cleaner malt flavor whichshould bring a smile to Ron Cooper’s face. The NelsonSauvin hops have a subtle green grape flavor.In July, I brewed Hefewiezen using Harold Gulbransen’srecipe and process that he discussed at the NHC.Harold’s beer includes 70% malted wheat, a singledecoction mash and fermentation at 62 o to get the maltflavor, mouthfeel and clove/banana intensity andbalance just right. I’ll have a complete report on hispresentation in Sept.I’ve brewed Hefewiezen without FTC and banana bombis the description that comes to mind. For this one, a1000ml starter of WLP-300 (Weihenstephan 68) waspitched at 59 o and fermentation was initially controlledto 61-63 o . Fermentation was slow to take off at thesetemperatures, but foam did cover the surface after 12hours. After 24 hours, the head was 4” thick andgrowing. After three days, temperature was allowed torise naturally to a max of 70 o and a FG of 1.011 wasreached in 11 days. The beer was then crashed to 40 ofor 2 days, kegged, carbonated and is conditioning now.The fridge cooling setup works fine and I have fivemonths to figure what kind of heater to use next winter.One bit of fall out is that I have an unopened 50’ coil of3/8” refrigeration tubing that I don’t need. Anyinterested buyers?This is the fridge’s first batch back in June. It’s an AIPAhopped with Summit for bittering and Nelson Sauvin forflavor and aroma. A 1000ml starter of WLP-002 yeast(Fuller’s) was pitched at 65 o and the first three days offermentation were controlled at 66-68 o beertemperature while ambient temperatures hovered inthe mid 70s during the day. After yeast growth slowed,temperature was allowed to rise freely untilfermentation was complete. The beer reached 74 o anda 1.010 FG. It rested for two days to reduce diacetyl andwas then crashed to 40 o before kegging. This spedCompetition CalendarRives Borland, Vice-President<strong>Club</strong>-Only Competitions<strong>Strand</strong> <strong>Brewers</strong>' <strong>Club</strong> MeetingTime: 2nd Wednesday of most months 7:00pm.Best entry at the club meeting will be sent to thejudging location.For more info on club-only competitions, go tohttp://www.homebrewersassociation.org/pages/competitions/club-only-competitionsAugust 2011 (bring entries to July or August SBCmeeting)