ECR58/ECR88 - Utleiesenteret AS

ECR58/ECR88 - Utleiesenteret AS

ECR58/ECR88 - Utleiesenteret AS

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

<strong>ECR58</strong> / <strong>ECR88</strong>

THE COMFORTABLE WAY TO GETINTO TIGHT SPACES.When your job takes you to an area where space isat a premium, turn to the Volvo <strong>ECR58</strong> and <strong>ECR88</strong>.Both models have a short swing radius for theultimate in maneuvrability. You won’t sacrificecomfort because the wide operator’s area hasplenty of features to make even the longest daystolerable.The <strong>ECR58</strong> and <strong>ECR88</strong> short swingradius machines are very compact andthe digging equipment can be offset soyou can work safely in confined spaceswithout the risk of hitting walls, obstaclesor other workers with the counterweight.The units are built for comfort, withspacious cabs that have a wide,uncluttered floor and plenty of legroom.The deluxe, adjustable suspension seathas a high back for excellent comfort.The joysticks and ergonomic armrestsare mounted to the consoles and can beadjusted independent of the seat forreduced fatigue and easy operation.There’s excellent visibility all aroundbecause of the large, flat glazed surfacearea on all sides, the thin cab pillars andthe wide windscreen. Exterior rearviewmirrors improve visibility and safety.Heating and air conditioning help keepthe cab comfortable at all times.In addition, the operator can see allkey machine functions because theinstrument panel is within easy view infront of the operatorEasy-grip, highly responsive controllevers provide precise movements andreduce operator fatigue. The right controllever also has a roller so you can controlthe accessory circuit with your fingertipsrather than the traditional foot pedal,allowing more foot space. A button onthe front of the joystick sends maximumflow to accessories for increased comfortand better productivity. In addition, large,easy-to-use travel pedals are durable forfrequent, intensive use.The cab is set on rubber mountings toreduce vibration from the hydraulics andengine and reduce operator fatigue. Inaddition, the quiet, new-generation Volvoengine reduces fatigue and improvessafety.• Short swing radius offers the ultimatemaneuvrability.• Heating and air conditioning keeps operatorcomfortable.2• Wide cab offers plenty of legroom for bettercomfort.

• Excellent performance even intight job sites.• Ergonomic armrests help reduceoperator fatigue.• Suspended consoles areadjustable independent of theseat.

OUTSTANDING PERFORMANCE ANDENVIRONMENTAL CARE.Performance is everything when it comes to compactexcavators - how much you can move per hour andhow quickly you get the job done. That’s why Volvofilled the <strong>ECR58</strong> and <strong>ECR88</strong> with features to helpyou power through the work.The short swing radius helps you to gowhere the work is. The models featureimpressive breakout and tear-out forces,allowing them to power through thetoughest working conditions.To work more efficiently the modelsfeature an auto-idling system that lowersthe engine speed to idle if the operatorcontrols are not used for five seconds ormore. The system returns the engine tothe pre-selected speed once theoperator uses any control. The auto-idlingreduces fuel consumption, decreasesnoise for better safety and a longerengine life.Both models feature automatictwo-speed travel. In high gear, the travelspeed is automatically shifted from highto low according to the travel load -perfect for levelling or backfilling work.The machines can also counter-rotateeven in high speed for maximum controland maneuvrability.The finger tip control for accessoriesenables the operator to progressivelyadjust the flow to the attachment formore precision.The load-sensing hydraulics are the besttechnology available, providing simplicityand efficiency. The speed of thehydraulic movements depends only onthe position of the power-assisted, multifunction control levers - regardless ofload and number of simultaneouscylinder movements - to instantly supplyonly the necessary power.A second independent circuit can allowcomplex accessories to be operated withease.Both machines have new-generationVolvo, 16 valve diesel engines thatprovide excellent performance.The engines are direct injection for fast,efficient mixing of fuel and air.Both models provide low exhaustemissions complying with the strictestlegal standards.• New Volvo engine offers excellent performance.• Auto-idling reduces fuel consumption and noise.4• Impressive breakout and tear-out forces.

• Progressive finger-tip control ofattachments.• Load sensing hydraulics forprecise movement.• Great view of the work for betterperformance.

ENDURING QUALITY IN A SAFE,EFFICIENT DESIGN.Tough work demands an even tougher machine -one that will stand up to the day-to-day assault ofdigging, grading and much more. The Volvo <strong>ECR58</strong>and <strong>ECR88</strong> are designed to stand up to work andkeep coming back for more. They are built to keepthe operator - and those around him - safe.The engine is on the side and there’s alarge hood that allows complete,unobstructed access to all routineservice points, including filters and fluidlevels. The fuse box is under the seat foreasy access. An electric pump delivers35 litres of fuel per minute for fast andeasy filling of the tank.The cab door can be locked open and itis protected on the inside of the chassisto prevent damage.There are many high quality features toensure a long life, such as bucketcylinder hoses that are protected on theinside of the dipper. The ORFS (O-RingFace Seal) technology of the hydraulicconnectors provides a leak-free joint,resisting pressure peaks, vibrations andtwisting. The wiring looms andconnectors are waterproof and meet theIP67 standards, protecting the cablesfrom their harsh operating environment.As with all Volvo products, the units offerthe best in safety to help protect theoperator. Volvo excavators comestandard with a FOPS 1, ROPS andTOPS safety structure to prevent injury.All machine controls are locked out whenthe console is raised to preventaccidents when the operator is gettinginto or out of the cab. This providessafety for those working near themachine.The blade is locked in position by asafety valve, so it can be used as a frontstabiliser. The laminated windscreen isdesigned to stay in one piece if it breaksfor increased operator safety.• Open door is protected in the widthof the chassis.• Laminated windscreen increase operator safety.6• High quality electrical and hydraulic connections.

• All controls lock out whenconsole is raised.• Instrument panel provides clearview of functions.• Side engine hood opens wide foreasy service.

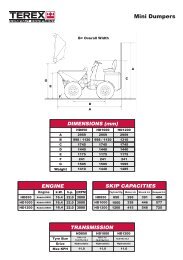

SPECIFICATIONS - <strong>ECR58</strong>EngineLow emission, water-cooled, direct injection Volvo 4-cylinderdiesel engine, meeting STEP 2 environmental regulations andequipped with an automatic return to idling system.Model Volvo D3.1Gross power, rated (ISO 9249)Power, installed (ISO 9249)Displacement, totalMaximum torqueBore x strokeElectrical systemBattery capacityAlternator ratingStarter motor output38.2 kW (52 hp) at 2100 r/min37.5 kW (51 hp) at 2100 r/min3054 cc200 Nm at 1400 r/min94 mm x 110 mm12 V - 100 Ah12 V - 55 A12 V - 3 kWSlewing systemTurntable slewing is provided by a radial piston hydraulic motorwhich drives directly (without a reduction gear) a ball internalcrown wheel with remote lubrication:Slewing speedTurntable brakingAbsorption of hydraulic shocks10 rpmautomatic multi-disc brakeShockless valveUndercarriageThe undercarriage is made up of an “X” box fabricated centrepart for more rigidity and of sloping side members for a betterclearance of materials. The rollers and the tensioning wheelsare lubricated for life.Bottom/top rollers per side 5 / 1Track widthRubber: 400 mmTrack tensionBlade (width x height)Steel: 380 mm or 500 mmby grease piston2000 x 370 mmSafety valve on the blade cylinder.Hydaulic systemClosed centre Load Sensing hydraulic system providing totalindependence of each movement.Controlpower-assisted hydraulic controlsVariable displacement Load Sensing pump for all the equipmentand travel circuits:Maximum flow130 l/minMaximum operating pressure24 MPa (240 bars)Gear pump for the power assistance circuit:Maximum flowMaximum operating pressure9.4 l/min3.3 MPa (33 bars)Finger-tip controlled double-acting hydraulic circuit foraccessories:Maximum adjustable flow 70 l/minMaximum operating pressure24 MPa (240 bars)DrivetrainEach track is driven by an axial piston hydraulic motor equippedwith two speeds and an epicyclic reduction gear.Braking is provided automatically by a multiple disc brake.Automatic 2 -speed Travel enables to automatically shift fromhigh to low speed according to the travel load.Max. speed(low speed/ high speed)Max. tractive force2.2 km/h / 4.3 km/h4600 daNThe travel control is automatically locked when the operatorraises the left console.End-of-stroke cushions:On boom ramOn dipper ramOn offset ramat the end of the rod extensionat the end of the rod retractionand extensionat the end of the rod retractionand extensionService fill capacitiesFuel tankHydraulic tankHydraulic system, totalEngine oilCooling system65 l50 l90 l11.5 l6.5 lBucket performanceBreakout forceTearout force3900 daN2700 daNWeightOperational weight and ground pressure:Rubber Tracks (400 mm) 5480 kg - 0.3 kg/cm 2Steel Tracks (380 mm) 5590 kg - 0.28 kg/cm 28

SPECIFICATIONS - <strong>ECR88</strong>EngineLow emission, water-cooled, direct injection Volvo 4-cylinderdiesel engine, meeting STEP 2 environmental regulations andequipped with an automatic return to idling system.Model Volvo D3.4Gross power, rated (ISO 9249)Power, installed (ISO 9249)Displacement, totalMaximum torqueBore x strokeElectrical systemBattery capacityAlternator ratingStarter motor output43.8 kW (59 hp) at 2100 r/min41.9 kW (57 hp) at 2100 r/min3318 cc235 Nm at 1400 r/min98 mm x 110 mm12 V - 100 Ah12 V - 55 A12 V - 3 kWSlewing systemTurntable slewing is provided by a radial piston hydraulic motorwhich drives directly (without a reduction gear) a ball internalcrown wheel with remote lubrication:Slewing speedTurntable brakingAbsorption of hydraulic shocks9.5 rpmautomatic multi-disc brakeShockless valveUndercarriageThe undercarriage is made up of an “X” box fabricated centrepart for more rigidity and of sloping side members for a betterclearance of materials. The rollers and the tensioning wheelsare lubricated for life.Bottom/top rollers per side 6 / 1Track widthRubber: 450 mmTrack tensionBlade (width x height)Steel: 450 mm or 600 mmby grease piston2300 x 470 mmSafety valve on the blade cylinder.Hydaulic systemClosed centre Load Sensing hydraulic system providing totalindependence of each movement.Controlpower-assisted hydraulic controlsVariable displacement Load Sensing pump for all the equipmentand travel circuits:Maximum flow174 l/minMaximum operating pressure30 MPa (300 bars)Gear pump for the power assistance circuit:Maximum flowMaximum operating pressure16.8 l/min3.3 MPa (33 bars)Finger-tip controlled double-acting hydraulic circuit foraccessories:Maximum adjustable flow 90 l/minMaximum operating pressure30 MPa (300 bars)DrivetrainEach track is driven by an axial piston hydraulic motor equippedwith two speeds and an epicyclic reduction gear.Braking is provided automatically by a multiple disc brake.Automatic 2 -speed Travel enables to automatically shift fromhigh to low speed according to the travel load.Max. speed(low speed/ high speed)Max. tractive force2.7 km/h / 5.1 km/h5450 daNThe travel control is automatically locked when the operatorraises the left console.End-of-stroke cushions:On boom ramOn dipper ramOn offset ramat the end of the rod extensionat the end of the rod retractionand extensionat the end of the rod retractionand extensionService fill capacitiesFuel tankHydraulic tankHydraulic system, totalEngine oilCooling system110 l80 l140 l11.5 l7.0 lBucket performanceBreakout forceTearout force5600 daN4100 daNWeightOperational weight and ground pressure:Rubber Tracks (450 mm) 8200 kg - 0.36 kg/cm 2Steel Tracks (450 mm) 8500 kg - 0.38 kg/cm 29

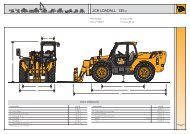

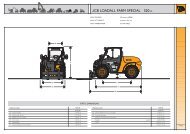

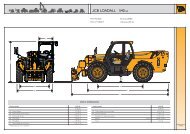

<strong>ECR58</strong>Dipper A B C C* D E F1540 mm 5610 3970 3600 3850 2910 5940 60801940 mm 5850 4210 4000 4240 3260 6320 6460G H I J K L M N O420 480 1950 2500 1820 2000 5600 1670 370P Q R S T 1 U V W X370 400 2 670 2470 1960 2580 4330 2000 1000* : Digging depth with the blade down1 : Front turning radius with maximum offset2 : Options : 380 / 500 mm (steel)Buckets<strong>ECR58</strong>StandardDitchWidth Weight Capacity350 mm 85 kg 70 l450 mm 97 kg 98 l600 mm 118 kg 142 l750 mm 138 kg 187 l900 mm 163 kg 231 l1300 mm 125 kg 175 l1500 mm 185 kg 265 l<strong>ECR88</strong>Dipper A B C C* D E F1700 mm 6740 4860 4170 4470 2890 6860 70102100 mm 7000 5120 4570 4870 3260 7240 7390G H I J K L M N O490 400 2200 2850 1940 2300 6410 1780 390P Q R S T 1 U V W X470 450 2 755 2570 2040 2680 5260 2265 1210* : Digging depth with the blade down1 : Front turning radius with maximum offset2 : Options : 450 / 600 mm (steel)Buckets<strong>ECR88</strong>StandardDitchWidth Weight Capacity380 mm 128 kg 103 l450 mm 150 kg 130 l600 mm 183 kg 188 l750 mm 218 kg 246 l900 mm 236 kg 306 l1500 mm 250 kg 265 l10

STANDARD EQUIPMENTEngineLow-emission Volvo diesel engine.Two-stage air filter with blinding indicator.Electric heating device.Fuel filter + transparent sediment chamber.Electric fuel tank filling pump (35 l/min).Drain valve under the diesel oil tank.Oil sump sheet metal guard.Automatic return to idling system.Electrical systemElectric circuit-breaker.Water-resistant electrical connectors(IP67).Undercarriage400 mm wide rubber tracks on <strong>ECR58</strong>.450 mm wide rubber tracks on <strong>ECR88</strong>.Dozer blade.Hydraulic systemLoad-sensing system.Multiple filtration system (30µm).ISO power-assisted hydraulic controls.Power-assisted control of the hydraulicoffset of the boom by the left controllever.Control of forward and backward movementby two levers coupled to pedals.Automatic 2 speed travel.Double-acting hydraulic circuit foraccessories fitted as far as the end ofthe arm.Cab installed switch to select the singleactingmode for direct return of oil to thehydraulic tank.Progressive finger-tip control of theaccessory circuit.CabMulti-adjustable fully-suspended consolesseatassembly.“Deluxe” fabric-covered superior comfortseat with a high back.Cab mounted on rubber mountings.Two working lights.Heating and air conditioning.Two-speed heating and ventilation.Cab heating adjustment.Tinted windows.Front window with opening system powerassistedby two gas rams.Radio/cassette player with 2 speakers.Windscreen wiper and washer (front).Instrumentation and monitoringWarning lights for hydraulic filter and airfilter restriction.Gauges : water temperature, fuel level.Hour meter.Warning lights, coupled to an audible signal,in the event of overheating or drop in oilpressure.Earthwork equipment<strong>ECR58</strong> :2900 mm long monobloc boom.1540 mm dipper arm.<strong>ECR88</strong> :3550 mm long monobloc boom.1700 mm dipper arm.SafetyLevel 1 FOPS (Falling Objects ProtectiveStructure).TOPS (Tip-Over Protective Structure).ROPS (Roll-Over Protective Structure).Device for locking the earthworkequipment’s controls and the travel leverswhen the left console is raised to gainaccess to the driver’s cab.Engine starting safety device : the leftconsole must be raised to operate thestarter.Pressure accumulator in order to be ableto put the equipment on the ground ifthe engine is switched off.Laminated glass front window.Retractable seatbelt.Tool kit.Official approvalMachine conforming to European directive98/37/EC.Noise emissions in the environmentconforming to directive 2000/14/EC.Object handling device conforming toEN 474-5 standard.FOPS 1 conforming to ISO 3449 standard.TOPS conforming to ISO 12117 andEN 13531 standards.Electromagnetic compatibility (EMC)conforming to European directive89/336/EC and its amendments.OPTIONAL EQUIPMENTHandling and earthwork equipmentLong dipper (1940 mm on <strong>ECR58</strong>,2100 mm on <strong>ECR88</strong>).Safety valve piloted by the powerassistance circuit on the boom ram withoverload indicator.Safety valve on the dipper ram.Hydraulically-controlled quick-changeattachment coupling.Single-acting or double-acting hydrauliccircuit for quick-coupling.Hydraulic circuits for attachmentsHydraulic circuit for operating a clam-shellbucket (opening/closing and rotation ofthe bucket).Additional adjustment roller of max.delivery available on the accessory circuit.Second hydraulic circuit for accessorieswith piping on the boom.UndercarriageSteel tracks :<strong>ECR58</strong> : 380 mm or 500 mm wide.<strong>ECR88</strong> : 450 mm or 600 mm wide.Cab“Deluxe” vinyl-covered superior comfortseat with a high back.LightingAdditional working light on the boom.Additional rear working light.Rotating beacon.Environmental protectionBio-degradable hydraulic oil.Comfort and safetyAnti-theft system (2 programmable codes).Side view mirrors.Level 2 FOPS.MiscellaneousSpecial customised paint(RAL specifications).11

Volvo Construction Equipment is different. It’s designed, builtand supported in a different way. That difference comes fromour 170-year engineering heritage. A heritage ofthinking firstabout the people who actually use the machines. About how tohelp them be safer, more comfortable, more productive. Aboutthe environment we all share. The result of that thinking is agrowing range of machines and a global support networkdedicated to helping you do more. People around the worldare proud to use Volvo. And we’re proud of what makesVolvo different – More care. Built In.All products are not available in all markets. Under our policy of continuous improvement, we reserve the right to changespecifications and design without prior notice. The illustrations do not necessarily show the standard version of the machine.Construction Equipmentwww.volvoce.comRef No. 21 1 432 1145 EnglishPrinted in Germany 2004.07Volvo, BelleyCEX