Atlas Copco Portable air compressors - Boramtech

Atlas Copco Portable air compressors - Boramtech

Atlas Copco Portable air compressors - Boramtech

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

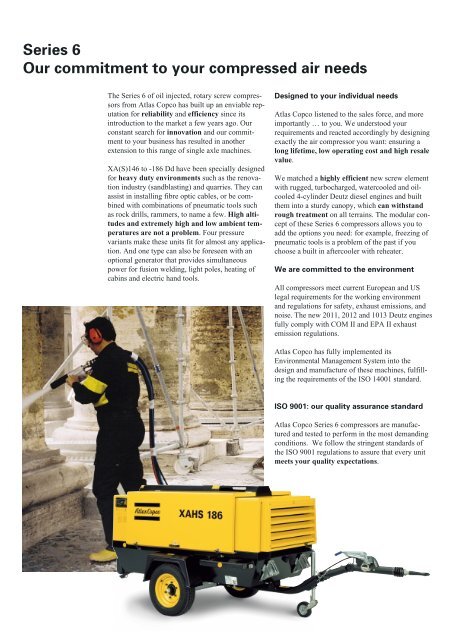

Series 6Our commitment to your compressed <strong>air</strong> needsThe Series 6 of oil injected, rotary screw <strong>compressors</strong>from <strong>Atlas</strong> <strong>Copco</strong> has built up an enviable reputationfor reliability and efficiency since itsintroduction to the market a few years ago. Ourconstant search for innovation and our commitmentto your business has resulted in anotherextension to this range of single axle machines.XA(S)146 to -186 Dd have been specially designedfor heavy duty environments such as the renovationindustry (sandblasting) and quarries. They canassist in installing fibre optic cables, or be combinedwith combinations of pneumatic tools suchas rock drills, rammers, to name a few. High altitudesand extremely high and low ambient temperaturesare not a problem. Four pressurevariants make these units fit for almost any application.And one type can also be foreseen with anoptional generator that provides simultaneouspower for fusion welding, light poles, heating ofcabins and electric hand tools.Designed to your individual needs<strong>Atlas</strong> <strong>Copco</strong> listened to the sales force, and moreimportantly … to you. We understood yourrequirements and reacted accordingly by designingexactly the <strong>air</strong> compressor you want: ensuring along lifetime, low operating cost and high resalevalue.We matched a highly efficient new screw elementwith rugged, turbocharged, watercooled and oilcooled4-cylinder Deutz diesel engines and builtthem into a sturdy canopy, which can withstandrough treatment on all terrains. The modular conceptof these Series 6 <strong>compressors</strong> allows you toadd the options you need: for example, freezing ofpneumatic tools is a problem of the past if youchoose a built in aftercooler with reheater.We are committed to the environmentAll <strong>compressors</strong> meet current European and USlegal requirements for the working environmentand regulations for safety, exhaust emissions, andnoise. The new 2011, 2012 and 1013 Deutz enginesfully comply with COM II and EPA II exhaustemission regulations.<strong>Atlas</strong> <strong>Copco</strong> has fully implemented itsEnvironmental Management System into thedesign and manufacture of these machines, fulfillingthe requirements of the ISO 14001 standard.ISO 9001: our quality assurance standard<strong>Atlas</strong> <strong>Copco</strong> Series 6 <strong>compressors</strong> are manufacturedand tested to perform in the most demandingconditions. We follow the stringent standards ofthe ISO 9001 regulations to assure that every unitmeets your quality expectations.