CAGE PROCESSING in Animal Facilities - GV-SOLAS

CAGE PROCESSING in Animal Facilities - GV-SOLAS

CAGE PROCESSING in Animal Facilities - GV-SOLAS

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

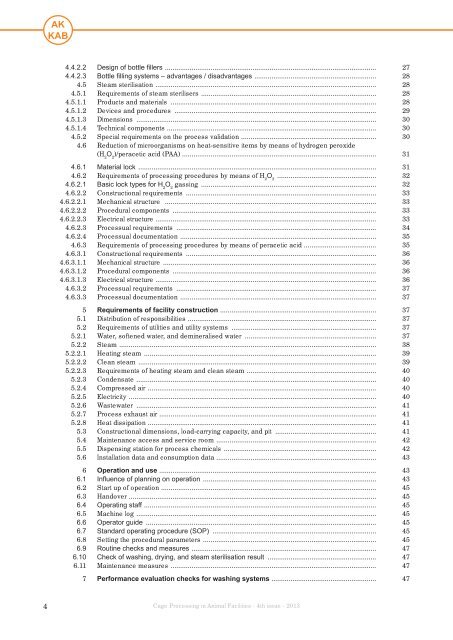

4.4.2.2 Design of bottle fillers ................................................................................................................ 274.4.2.3 Bottle fill<strong>in</strong>g systems – advantages / disadvantages ................................................................. 284.5 Steam sterilisation ..................................................................................................................... 284.5.1 Requirements of steam sterilisers ............................................................................................. 284.5.1.1 Products and materials ............................................................................................................. 284.5.1.2 Devices and procedures ........................................................................................................... 294.5.1.3 Dimensions ............................................................................................................................... 304.5.1.4 Technical components ............................................................................................................... 304.5.2 Special requirements on the process validation ........................................................................ 304.6 Reduction of microorganisms on heat-sensitive items by means of hydrogen peroxide(H 2O 2)/peracetic acid (PAA) ....................................................................................................... 314.6.1 Material lock .............................................................................................................................. 314.6.2 Requirements of process<strong>in</strong>g procedures by means of H 2O 2..................................................... 324.6.2.1 Basic lock types for H 2O 2gass<strong>in</strong>g ............................................................................................. 324.6.2.2 Constructional requirements ..................................................................................................... 334.6.2.2.1 Mechanical structure ................................................................................................................ 334.6.2.2.2 Procedural components ............................................................................................................ 334.6.2.2.3 Electrical structure ..................................................................................................................... 334.6.2.3 Processual requirements .......................................................................................................... 344.6.2.4 Processual documentation ........................................................................................................ 354.6.3 Requirements of process<strong>in</strong>g procedures by means of peracetic acid ....................................... 354.6.3.1 Constructional requirements ..................................................................................................... 364.6.3.1.1 Mechanical structure ................................................................................................................. 364.6.3.1.2 Procedural components ............................................................................................................ 364.6.3.1.3 Electrical structure ..................................................................................................................... 364.6.3.2 Processual requirements .......................................................................................................... 374.6.3.3 Processual documentation ........................................................................................................ 375 Requirements of facility construction ................................................................................... 375.1 Distribution of responsibilities .................................................................................................... 375.2 Requirements of utilities and utility systems ............................................................................. 375.2.1 Water, softened water, and dem<strong>in</strong>eralised water ...................................................................... 375.2.2 Steam ........................................................................................................................................ 385.2.2.1 Heat<strong>in</strong>g steam ........................................................................................................................... 395.2.2.2 Clean steam .............................................................................................................................. 395.2.2.3 Requirements of heat<strong>in</strong>g steam and clean steam ..................................................................... 405.2.3 Condensate ............................................................................................................................... 405.2.4 Compressed air ......................................................................................................................... 405.2.5 Electricity ................................................................................................................................... 405.2.6 Wastewater ............................................................................................................................... 415.2.7 Process exhaust air ................................................................................................................... 415.2.8 Heat dissipation ......................................................................................................................... 415.3 Constructional dimensions, load-carry<strong>in</strong>g capacity, and pit ...................................................... 415.4 Ma<strong>in</strong>tenance access and service room ..................................................................................... 425.5 Dispens<strong>in</strong>g station for process chemicals ................................................................................. 425.6 Installation data and consumption data ..................................................................................... 436 Operation and use ................................................................................................................... 436.1 Influence of plann<strong>in</strong>g on operation ............................................................................................ 436.2 Start up of operation .................................................................................................................. 456.3 Handover ................................................................................................................................... 456.4 Operat<strong>in</strong>g staff ........................................................................................................................... 456.5 Mach<strong>in</strong>e log ............................................................................................................................... 456.6 Operator guide .......................................................................................................................... 456.7 Standard operat<strong>in</strong>g procedure (SOP) ....................................................................................... 456.8 Sett<strong>in</strong>g the procedural parameters ............................................................................................ 456.9 Rout<strong>in</strong>e checks and measures .................................................................................................. 476.10 Check of wash<strong>in</strong>g, dry<strong>in</strong>g, and steam sterilisation result .......................................................... 476.11 Ma<strong>in</strong>tenance measures ............................................................................................................. 477 Performance evaluation checks for wash<strong>in</strong>g systems ........................................................ 474Cage Process<strong>in</strong>g <strong>in</strong> <strong>Animal</strong> <strong>Facilities</strong> · 4th issue · 2013