Chemical Industry pdf, 3.7 MB - GEA Westfalia Separator

Chemical Industry pdf, 3.7 MB - GEA Westfalia Separator

Chemical Industry pdf, 3.7 MB - GEA Westfalia Separator

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

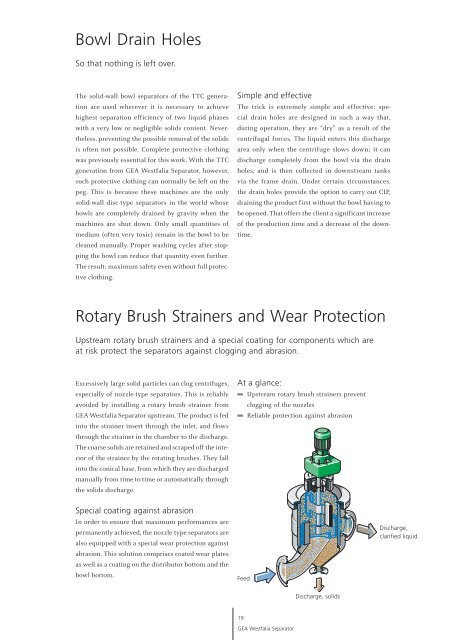

Bowl Drain HolesSo that nothing is left over.The solid-wall bowl separators of the TTC generationare used wherever it is necessary to achievehighest separation efficiency of two liquid phaseswith a very low or negligible solids content. Nevertheless,preventing the possible removal of the solidsis often not possible. Complete protective clothingwas previously essential for this work. With the TTCgeneration from <strong>GEA</strong> <strong>Westfalia</strong> <strong>Separator</strong>, however,such protective clothing can normally be left on thepeg. This is because these machines are the onlysolid-wall disc-type separators in the world whosebowls are completely drained by gravity when themachines are shut down. Only small quantities ofmedium (often very toxic) remain in the bowl to becleaned manually. Proper washing cycles after stoppingthe bowl can reduce that quantity even further.The result: maximum safety even without full protectiveclothing.Simple and effectiveThe trick is extremely simple and effective: specialdrain holes are designed in such a way that,during operation, they are “dry” as a result of thecentrifugal forces. The liquid enters this dischargearea only when the centrifuge slows down; it candischarge completely from the bowl via the drainholes, and is then collected in downstream tanksvia the frame drain. Under certain circumstances,the drain holes provide the option to carry out CIP,draining the product first without the bowl having tobe opened. That offers the client a significant increaseof the production time and a decrease of the downtime.Rotary Brush Strainers and Wear ProtectionUpstream rotary brush strainers and a special coating for components which areat risk protect the separators against clogging and abrasion.Excessively large solid particles can clog centrifuges,especially of nozzle-type separators. This is reliablyavoided by installing a rotary brush strainer from<strong>GEA</strong> <strong>Westfalia</strong> <strong>Separator</strong> upstream. The product is fedinto the strainer insert through the inlet, and flowsthrough the strainer in the chamber to the discharge.The coarse solids are retained and scraped off the interiorof the strainer by the rotating brushes. They fallinto the conical base, from which they are dischargedmanually from time to time or automatically throughthe solids discharge.At a glance:Upstream rotary brush strainers preventclogging of the nozzlesReliable protection against abrasionSpecial coating against abrasionIn order to ensure that maximum performances arepermanently achieved, the nozzle-type separators arealso equipped with a special wear protection againstabrasion. This solution comprises coated wear platesas well as a coating on the distributor bottom and thebowl bottom.FeedDischarge,clarified liquidDischarge, solids19<strong>GEA</strong> <strong>Westfalia</strong> <strong>Separator</strong>