CONTROLS

314 Parts - Peelle Company

314 Parts - Peelle Company

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

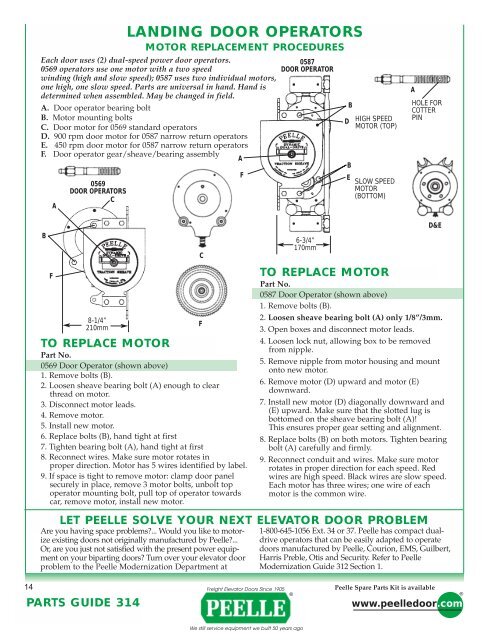

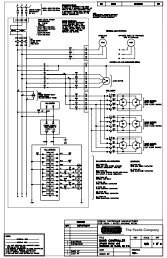

LANDING DOOR OPERATORSMOTOR REPLACEMENT PROCEDURESEach door uses (2) dual-speed power door operators.0569 operators use one motor with a two speedwinding (high and slow speed); 0587 uses two individual motors,one high, one slow speed. Parts are universal in hand. Hand isdetermined when assembled. May be changed in field.A. Door operator bearing boltB. Motor mounting boltsC. Door motor for 0569 standard operatorsD. 900 rpm door motor for 0587 narrow return operatorsE. 450 rpm door motor for 0587 narrow return operatorsF. Door operator gear/sheave/bearing assemblyAA0569DOOR OPERATORSCF0587DOOR OPERATORDBBEHIGH SPEEDMOTOR (TOP)SLOW SPEEDMOTOR(BOTTOM)AHOLE FORCOTTERPINBF8-1/4”210mmTO REPLACE MOTORPart No.0569 Door Operator (shown above)1. Remove bolts (B).2. Loosen sheave bearing bolt (A) enough to clearthread on motor.3. Disconnect motor leads.4. Remove motor.5. Install new motor.6. Replace bolts (B), hand tight at first7. Tighten bearing bolt (A), hand tight at first8. Reconnect wires. Make sure motor rotates inproper direction. Motor has 5 wires identified by label.9. If space is tight to remove motor: clamp door panelsecurely in place, remove 3 motor bolts, unbolt topoperator mounting bolt, pull top of operator towardscar, remove motor, install new motor.CF6-3/4”170mmTO REPLACE MOTORLET PEELLE SOLVE YOUR NEXT ELEVATOR DOOR PROBLEMAre you having space problems?... Would you like to motorizeexisting doors not originally manufactured by Peelle?...Or, are you just not satisfied with the present power equipmenton your biparting doors? Turn over your elevator doorproblem to the Peelle Modernization Department atD&EPart No.0587 Door Operator (shown above)1. Remove bolts (B).2. Loosen sheave bearing bolt (A) only 1/8”/3mm.3. Open boxes and disconnect motor leads.4. Loosen lock nut, allowing box to be removedfrom nipple.5. Remove nipple from motor housing and mountonto new motor.6. Remove motor (D) upward and motor (E)downward.7. Install new motor (D) diagonally downward and(E) upward. Make sure that the slotted lug isbottomed on the sheave bearing bolt (A)!This ensures proper gear setting and alignment.8. Replace bolts (B) on both motors. Tighten bearingbolt (A) carefully and firmly.9. Reconnect conduit and wires. Make sure motorrotates in proper direction for each speed. Redwires are high speed. Black wires are slow speed.Each motor has three wires; one wire of eachmotor is the common wire.1-800-645-1056 Ext. 34 or 37. Peelle has compact dualdriveoperators that can be easily adapted to operatedoors manufactured by Peelle, Courion, EMS, Guilbert,Harris Preble, Otis and Security. Refer to PeelleModernization Guide 312 Section 1.14PARTS GUIDE 314Freight Elevator Doors Since 1905®Peelle Spare Parts Kit is availablewww.peelledoor.com®We still service equipment we built 50 years ago