PRECAST PARKING STRUCTURES

PCI Maintenance Manual for Precast Parking Structures - Clark Pacific

PCI Maintenance Manual for Precast Parking Structures - Clark Pacific

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

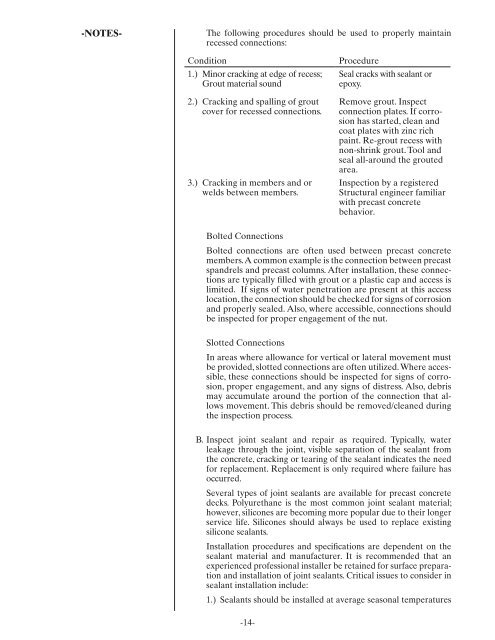

-14--NOTES-The following procedures should be used to properly maintainrecessed connections:Condition1.) Minor cracking at edge of recess;Grout material sound2.) Cracking and spalling of groutcover for recessed connections.3.) Cracking in members and orwelds between members.ProcedureSeal cracks with sealant orepoxy.Remove grout. Inspectconnection plates. If corrosionhas started, clean andcoat plates with zinc richpaint. Re-grout recess withnon-shrink grout. Tool andseal all-around the groutedarea.Inspection by a registeredStructural engineer familiarwith precast concretebehavior.Bolted ConnectionsBolted connections are often used between precast concretemembers. A common example is the connection between precastspandrels and precast columns. After installation, these connectionsare typically filled with grout or a plastic cap and access islimited. If signs of water penetration are present at this accesslocation, the connection should be checked for signs of corrosionand properly sealed. Also, where accessible, connections shouldbe inspected for proper engagement of the nut.Slotted ConnectionsIn areas where allowance for vertical or lateral movement mustbe provided, slotted connections are often utilized. Where accessible,these connections should be inspected for signs of corrosion,proper engagement, and any signs of distress. Also, debrismay accumulate around the portion of the connection that allowsmovement. This debris should be removed/cleaned duringthe inspection process.B. Inspect joint sealant and repair as required. Typically, waterleakage through the joint, visible separation of the sealant fromthe concrete, cracking or tearing of the sealant indicates the needfor replacement. Replacement is only required where failure hasoccurred.Several types of joint sealants are available for precast concretedecks. Polyurethane is the most common joint sealant material;however, silicones are becoming more popular due to their longerservice life. Silicones should always be used to replace existingsilicone sealants.Installation procedures and specifications are dependent on thesealant material and manufacturer. It is recommended that anexperienced professional installer be retained for surface preparationand installation of joint sealants. Critical issues to consider insealant installation include:1.) Sealants should be installed at average seasonal temperatures